Laminated film structure, multi-mode piezoelectric type miniature ultrasonic transducer and manufacturing method

A technology of ultrasonic transducers and laminated films, applied in piezoelectric effect/electrostrictive or magnetostrictive motors, electrical components, generators/motors, etc., can solve the problem of increasing device volume, power consumption, and complex design In order to achieve the effects of easy integration and array, flexible design, and simple production

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

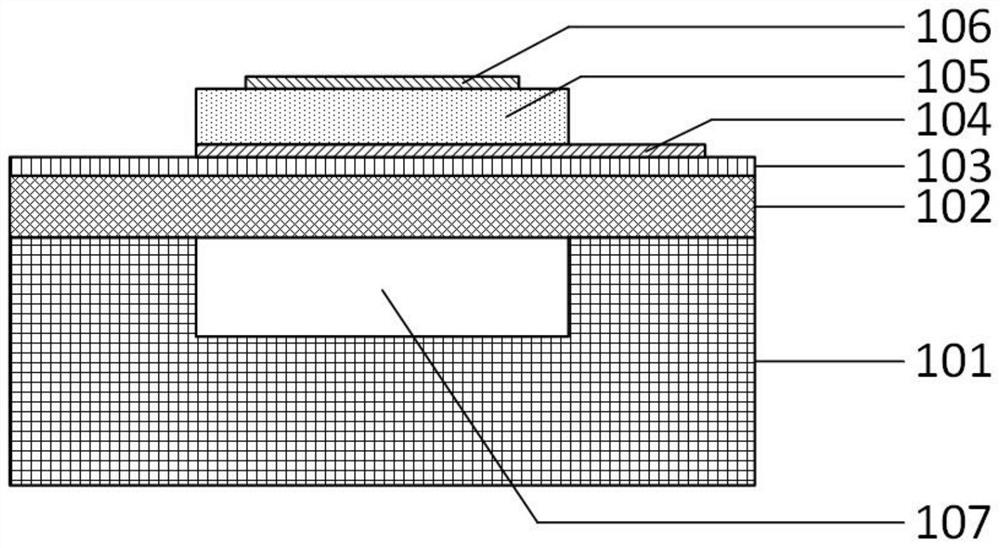

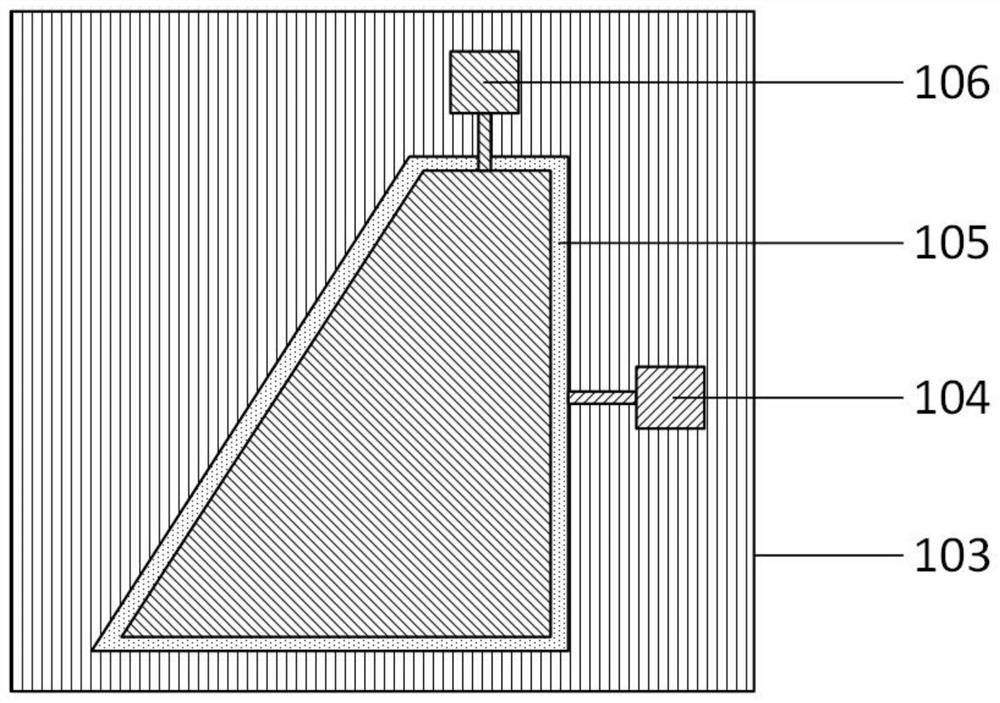

[0024] Embodiment 1 of the present invention provides a laminated film structure, which includes a substrate 101, a support film 102, an insulating film 103, a bottom electrode 104, a piezoelectric film 105 and a top electrode stacked sequentially from bottom to top. electrode 106 . Such as figure 1 with figure 2 As shown, the upper surface of the substrate 101 is recessed downwards to provide a cavity structure 107, and the horizontal cross-sectional shape of the cavity structure 107 is a non-axissymmetrical shape; the support film 102 covers the substrate 101 The upper port of the cavity structure 107 is completely sealed; the piezoelectric film 105 is arranged between the bottom electrode 104 and the top electrode 106, and its horizontal cross-sectional shape is a non-axissymmetric shape consistent with the cavity structure 107, and The position of the piezoelectric film 105 on the bottom electrode 104 is also set corresponding to the up and down mapping of the cavity st...

Embodiment 2

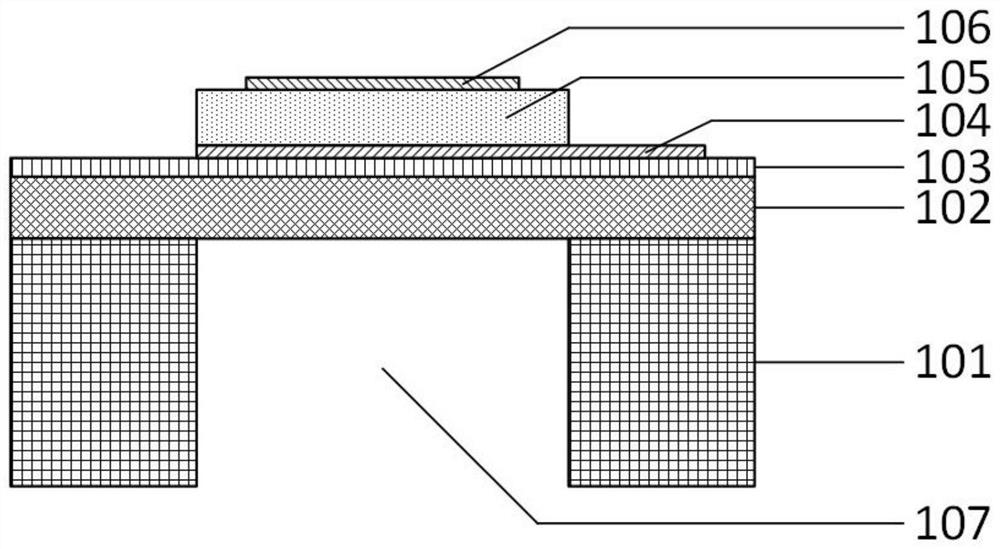

[0032] Embodiment 2 of the present invention provides a laminated film structure, which includes a substrate 101, a support film 102, an insulating film 103, a bottom electrode 104, a piezoelectric film 105 and a top electrode stacked sequentially from bottom to top. electrode 106 . Such as image 3 As shown, the upper surface of the substrate 101 is recessed downward, and a cavity structure 107 connecting the upper surface and the lower surface of the substrate 101 is provided, and the horizontal cross-sectional shape of the cavity structure 107 is a non-axissymmetric shape; The support film 102 covers the upper surface of the substrate 101, and completely seals the upper port of the cavity structure 107; the piezoelectric film 105 is arranged between the bottom electrode 104 and the top electrode 106, and its horizontal cross-sectional shape is the same as that of the cavity structure 107. The cavity structure 107 has a consistent non-axissymmetric shape, and the position o...

Embodiment 3

[0036] Embodiment 3 of the present invention provides a laminated film structure, which includes a substrate 101, a support film 102, an insulating film 103, a bottom electrode 104, a piezoelectric film 105 and a top electrode stacked sequentially from bottom to top. electrode 106 . Such as Figure 4 As shown, the upper surface of the substrate 101 is recessed downward, and a cavity structure 107 connecting the upper surface and the lower surface of the substrate 101 is provided, and the horizontal cross-sectional shape of the cavity structure 107 is a non-axissymmetric shape; The support film 102 covers the upper surface of the substrate 101, and completely seals the upper port of the cavity structure 107; the piezoelectric film 105 is arranged between the bottom electrode 104 and the top electrode 106, and its horizontal cross-sectional shape is the same as that of the cavity structure 107. The cavity structure 107 has a consistent non-axissymmetric shape, and the position ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com