Method for actuating a dosing valve, tank ventilation system, and motor vehicle

A technology of exhaust system and metering valve, applied in the direction of electrical control, charging system, engine control, etc., can solve problems such as large extra load, negative impact of storage tank exhaust system, large quality risk, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

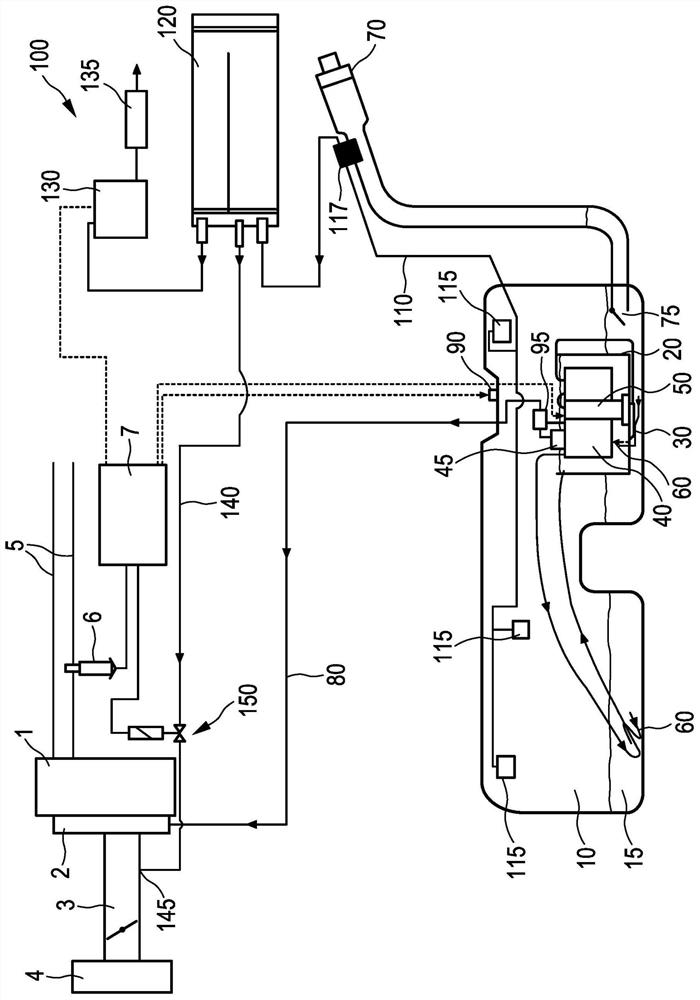

[0053] figure 1 An internal combustion engine 1 with further components, a tank 10 with further components and a tank venting system 100 according to one exemplary embodiment are shown. These constituents and others will be described below. In particular, the component shown can be part of a motor vehicle according to one exemplary embodiment.

[0054] Internal combustion engine 1 is a conventional internal combustion engine of a motor vehicle. In particular, this can be an Otto engine, since the components described below can be used particularly advantageously in Otto engines. However, it can also be another internal combustion engine.

[0055] An injection rail 2 is mounted on the internal combustion engine 1 , and the injection rail is in turn connected to an intake duct 3 . The intake pipe 3 is connected with an air filter 4 .

[0056] The internal combustion engine 1 is also connected to an exhaust system 5 , to which an oxygen sensor 6 is connected. Oxygen sensor ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com