High-strength spraying-free engineering material and preparation device

A technology for engineering materials and preparation devices, which is applied to heating devices, lighting and heating equipment, dryers, etc., can solve the problems of insufficient compactness between structures, limited movement of drying frames, and inability to sample, detect and mold items, and reduce direct churn effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

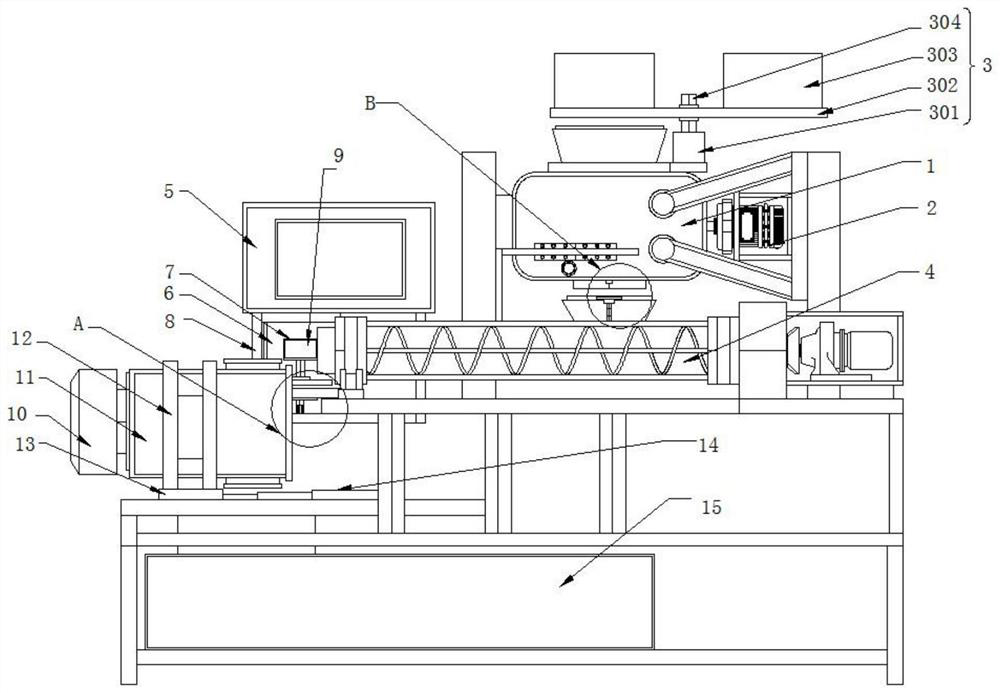

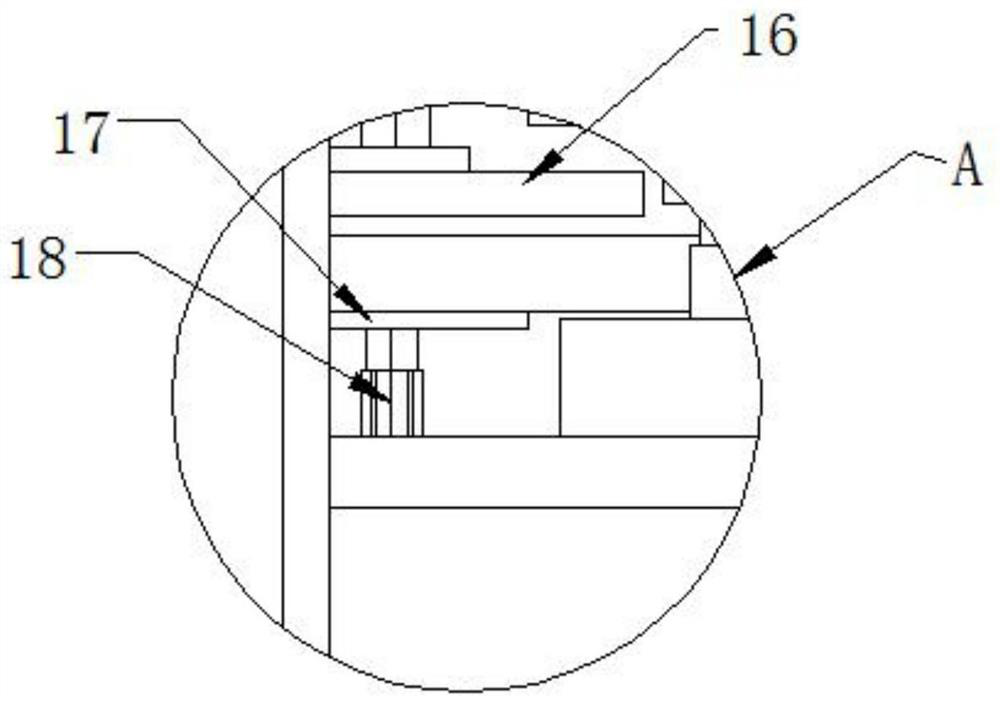

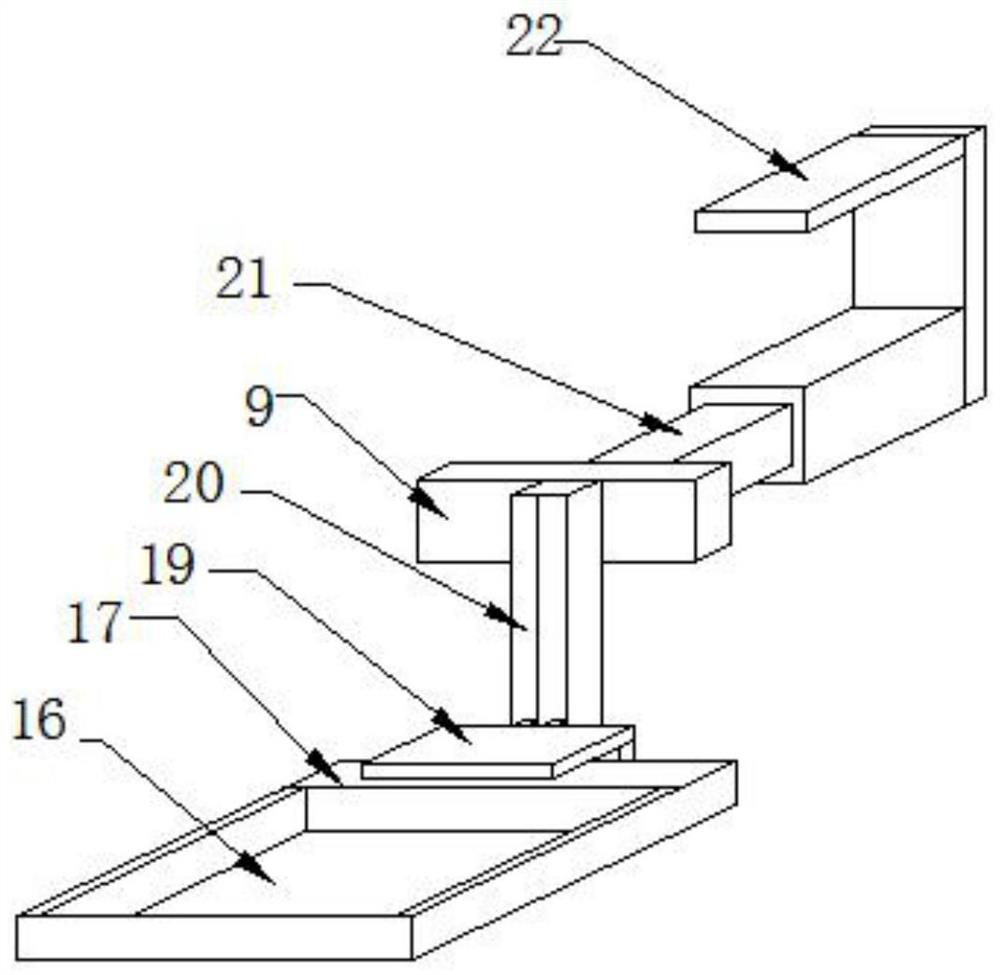

[0029] see Figure 1 to Figure 6, the present invention provides a technical solution: a high-strength spray-free engineering material and preparation device, including a stirring frame 1, a stirring motor 2, an adjustment assembly 3, an auxiliary motor 301, a connecting plate 302, an external frame 303, a connecting shaft 304, Extruder 4, baffle plate 5, detection frame 6, limit groove 7, slideway 8, built-in plate 9, servo motor 10, drying frame 11, limit plate 12, connecting seat 13, hydraulic cylinder 14, injection molding machine 15 , material receiving plate 16, push plate 17, electric push rod 18, adapter block 19, vertical rod 20, first hydraulic air rod 21, mounting plate 22, fastening cover 23, auxiliary component 24, built-in cavity 241, first Material port 242, card cavity 243, built-in baffle plate 244, second material port 245, closing cover 246, second hydraulic air rod 25, positioning plate 26, storage frame 27, material leakage port 28, fixing plate 29, materi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com