Drilling tool supporting mechanism

A technology for drilling tools and transmission mechanisms, which is applied to drill pipes, drill pipes, drilling equipment, etc., can solve problems such as potential safety hazards and poor work reliability, so as to reduce oil leakage hazards, reduce on-site pollution, and respond to fast effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0048] The present invention will be further described in detail below in conjunction with test examples and specific embodiments. However, it should not be understood that the scope of the above subject matter of the present invention is limited to the following embodiments, and all technologies realized based on the content of the present invention belong to the scope of the present invention.

[0049] This embodiment provides a drilling tool supporting mechanism.

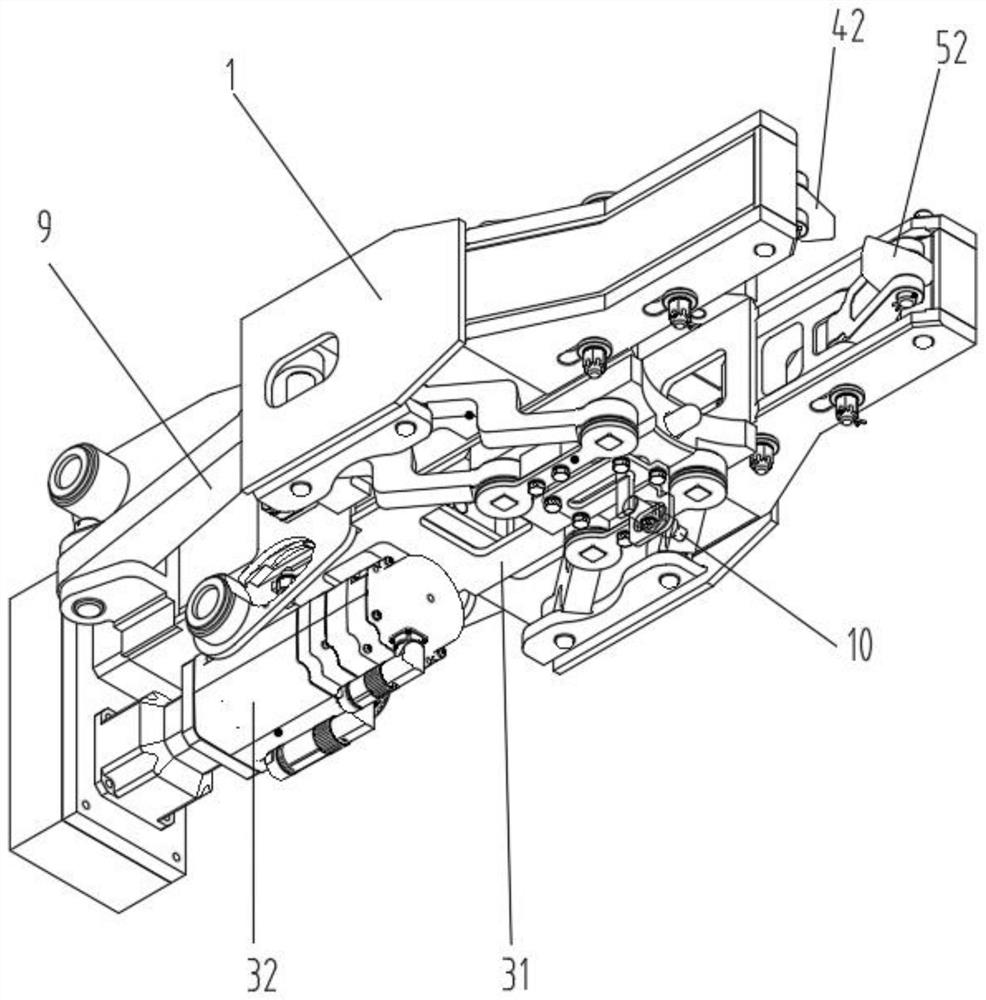

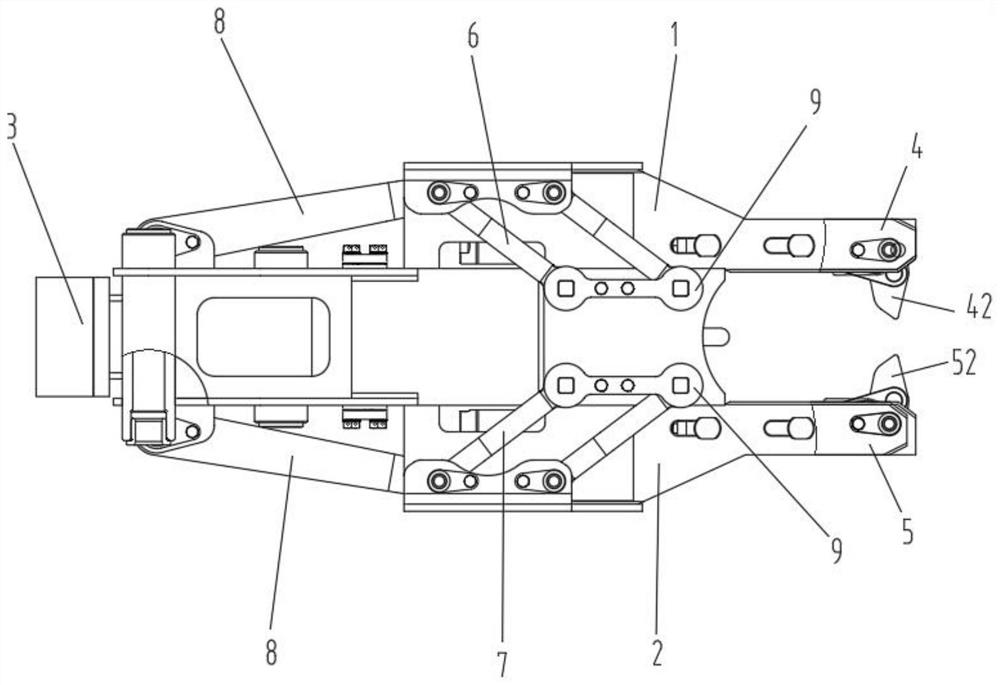

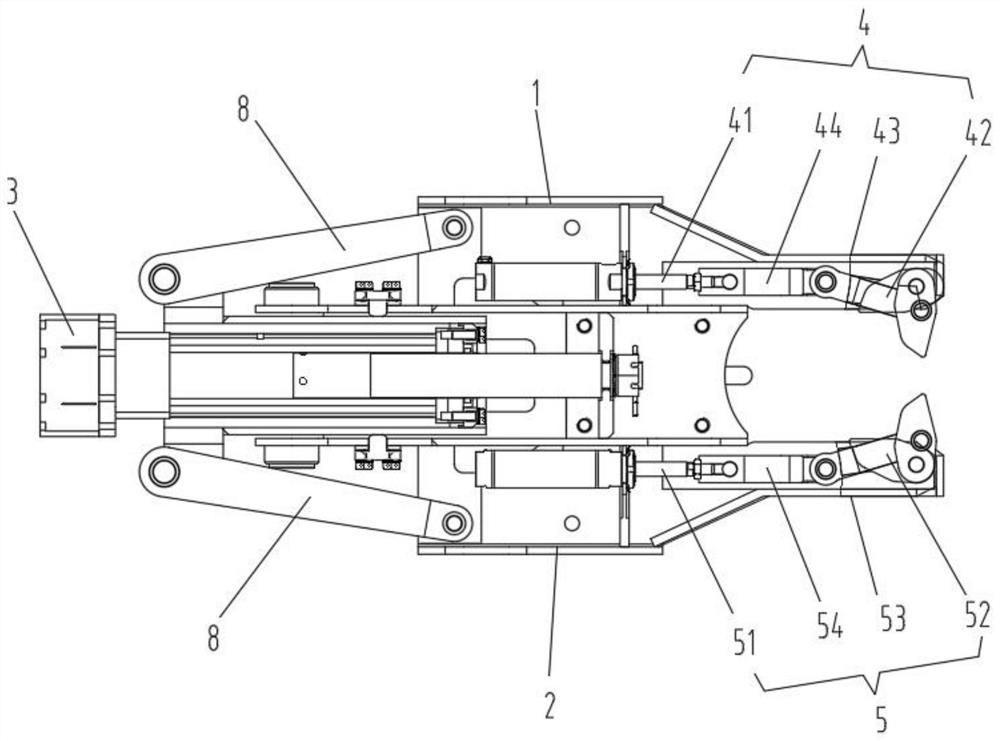

[0050] Such as Figure 1 to Figure 6 As shown, this embodiment includes a transmission mechanism 3 , a first grab bar 1 and a second grab bar 2 . The transmission mechanism 3 includes a pincer head outer cylinder 31 and a telescoping driving member 32 . In this embodiment, the first grab bar 1 and the second grab bar 2 are arranged oppositely, and the first grab bar 1 and the second grab bar 2 are respectively located on two sides of the outer cylinder 31 of the pliers head. exist Figure 4 In the shown view,...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap