Gas leakage detection device for gas pipeline

A technology for gas pipelines and detection devices, applied in pipeline systems, can solve problems such as aging and corrosion of gas, leakage, loss, etc. by detecting the appearance of fluids, gas/liquid distribution and storage at leakage points

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

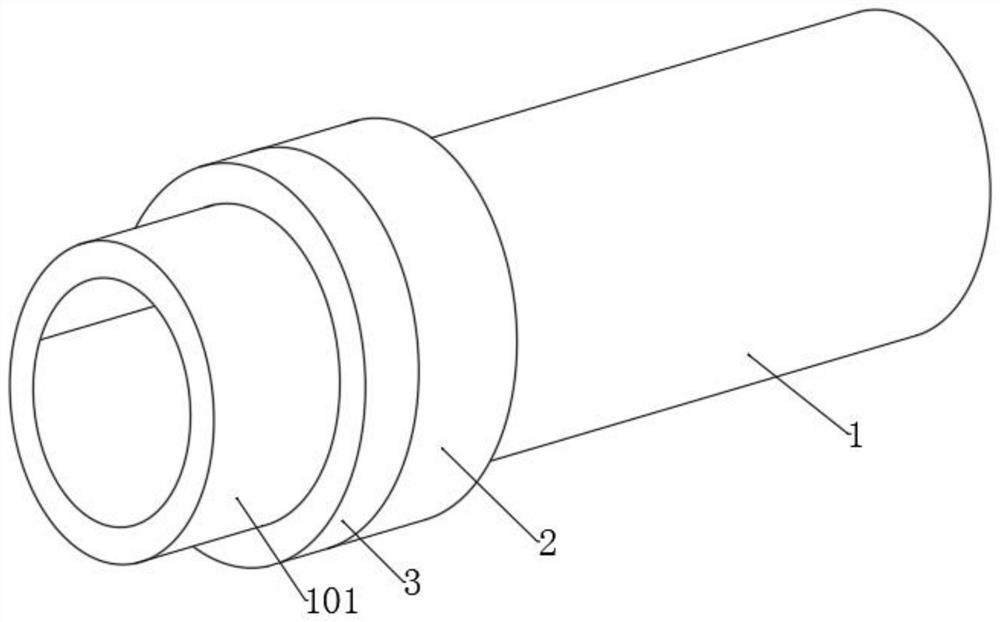

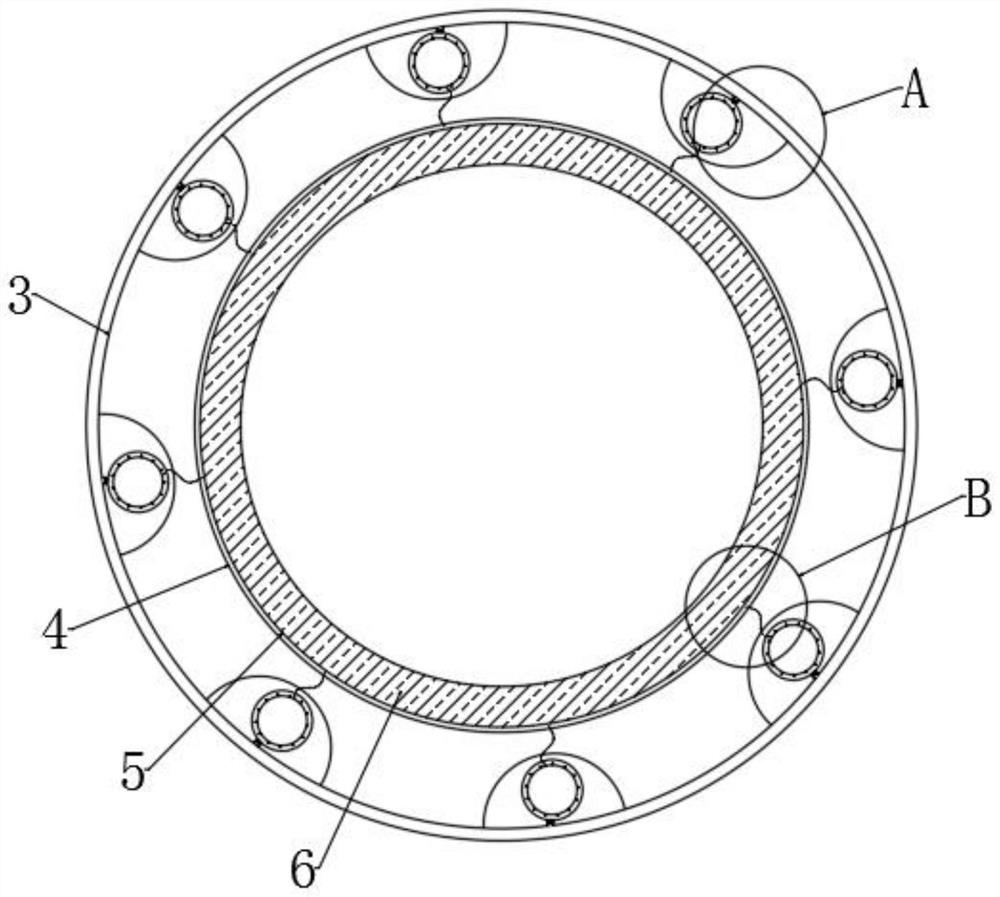

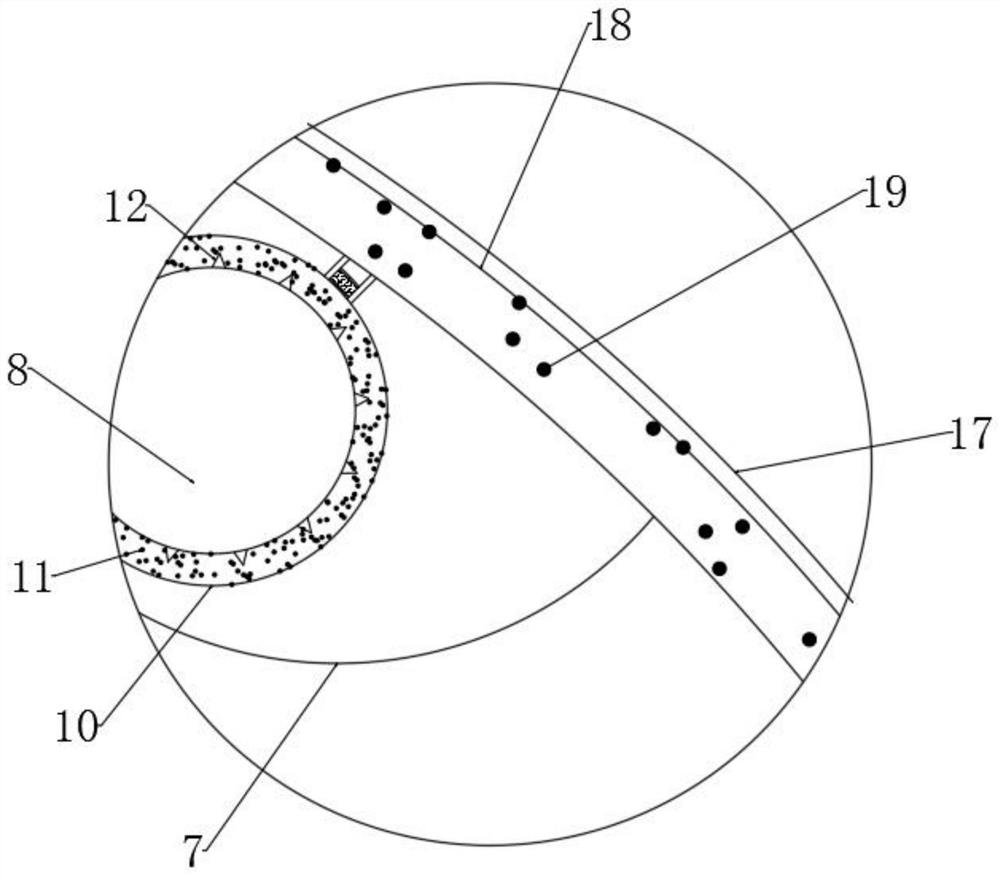

[0042] see Figure 1-5 , a gas pipeline gas leakage detection device, comprising a gas pipeline 1, the outer end of the gas pipeline 1 is fixedly connected with a connecting flange 2, the end of the connecting flange 2 away from the gas pipeline 1 is fixedly connected with a sealing ring 3, and the inner wall of the sealing ring 3 is fixed Connected with a storage sleeve 4, the inner wall of the storage sleeve 4 is fixedly connected with a liquid storage bag 5, the inner cavity of the liquid storage bag 5 is provided with an aqueous solution 6, and the outer end of the sealing ring 3 is dug with a plurality of evenly distributed spherical grooves 7, and the spherical groove 7 is equipped with There is an inflatable balloon 8, a water guide rope 9 is fixedly connected between the inflatable balloon 8 and the storage sleeve 4, the water guide rope 9 runs through the storage sleeve 4, the outer end of the inflatable balloon 8 is fixedly connected with a storage bag 10, and the ins...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com