Traveling mechanism of reactor pressure vessel bolt hole video scanning device

A technology of pressure vessel and scanning device, which is applied in the fields of nuclear reactor monitoring, reactor, nuclear power generation, etc., can solve the problems of low transmission efficiency of worm gear and worm mechanism, complicated structure of scanning device, high processing accuracy requirements, etc., so as to achieve convenient and reliable transmission of power. , The effect of easy on-site maintenance and simple structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0016] Below in conjunction with the embodiment shown in the accompanying drawings, the present invention is described in detail as follows:

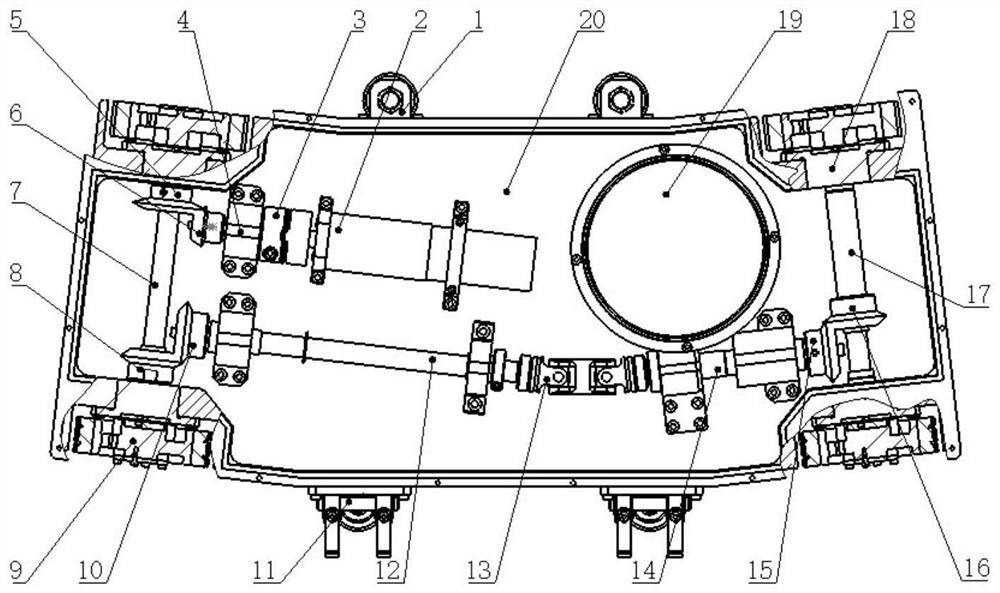

[0017] like figure 1 As shown, the running mechanism of the reactor pressure vessel bolt hole video scanning device includes a casing 20 provided with bolt holes 19, a wheel front axle 7 and a wheel rear axle 17 that are rotatably connected to the casing 20, and are installed on the wheel front axle 7 And the wheel on the wheel rear axle 17, and the driving part for driving the wheel to rotate, the wheel front axle 7 and the wheel rear axle 17 are coplanar and the extension line of both axes passes through the arc-shaped circle of the end face of the pressure vessel. The front axle 7 of the wheel is coplanar with the rear axle 17 of the wheel, and the angle formed by the intersection of the extension lines of both axes is less than 90°, which is 13° in this embodiment.

[0018] The driving part includes a first coupling 3 installed on ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com