Method for reducing etching marks of silver nanowire conducting film

A technology of nano-silver wire and conductive film, which is applied in the manufacture of circuits, electrical components, cables/conductors, etc. It can solve the problems of reducing light scattering and reflection, complex process, and difficulty in handling large-sized conductive films, etc., to reduce etching marks Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

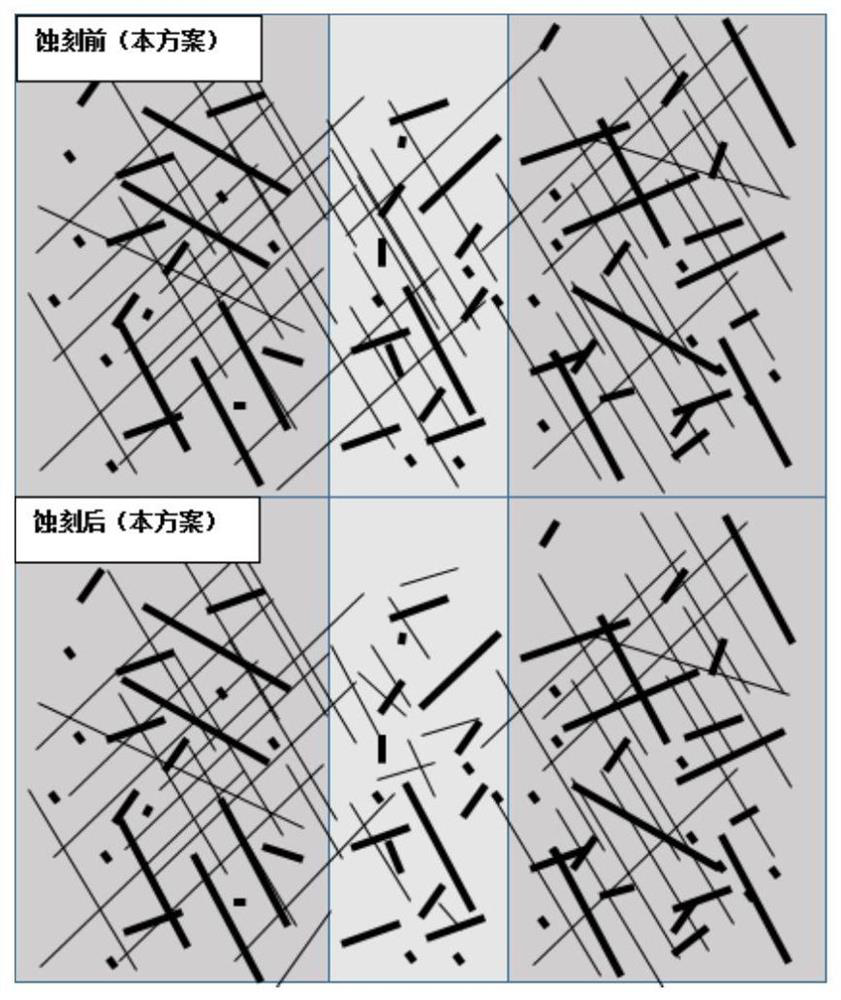

[0031] Embodiment 1: The conductive material is the conductive film of nano-silver wire + nano-silver rod + silver particles is etched

[0032] Combining conductive materials (nano-silver wire, nano-silver rod and silver particles, the diameter of the nano-silver wire is 27-30nm, the length is 5-16μm, the diameter of the silver rod is 50-200nm, the length is 0.5-10μm, the silver particle is The diameter is 50nm-5μm, wherein the content of silver nanowires is 70%, the total content of silver rods and silver particles is 30%), and the nano-silver ink with a content of 0.14wt% is coated on the surface of the substrate PET, and placed at 100 ° C for drying , after drying, apply a protective layer (OC for short) on its surface, dry at 100°C and then cure at 175°C for 5 minutes to obtain a conductive film; print the etching paste on the conductive film with a printing width of 150 μm, at 120°C Leave it for 30 minutes, and clean it with water after etching.

[0033] The schematic di...

Embodiment 2

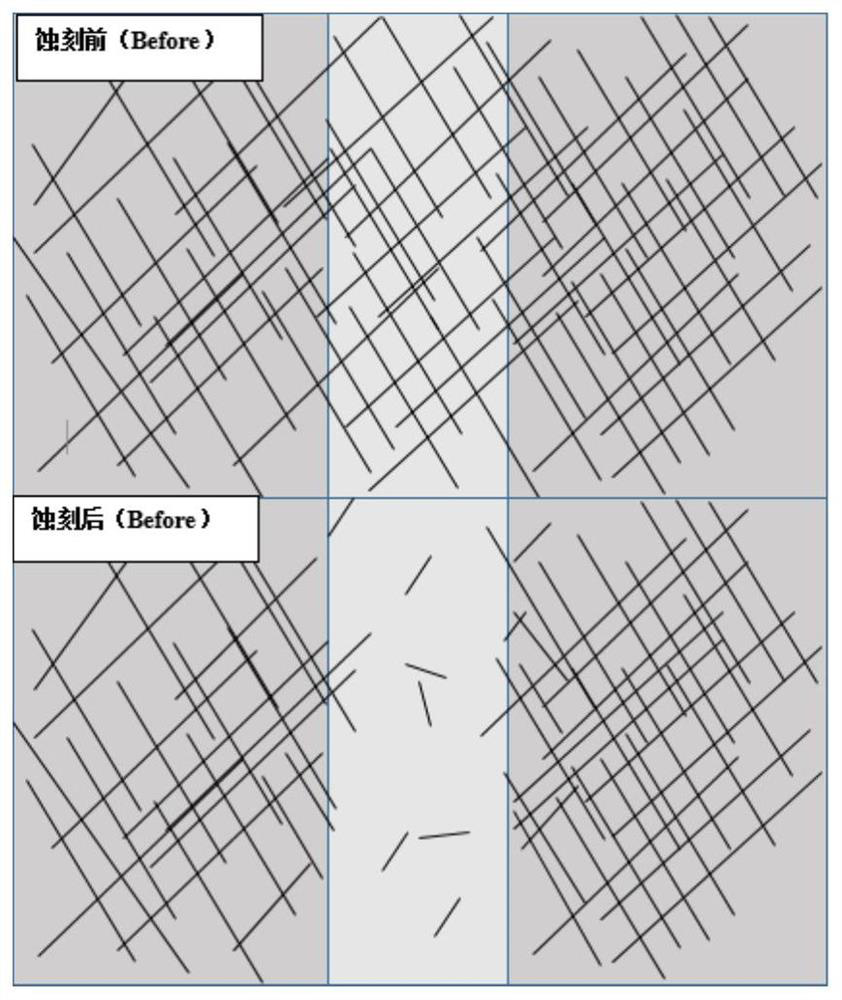

[0034] Embodiment 2: Etching the conductive film whose conductive material is nano-silver wire+gold-coated silver nano-wire

[0035] Combining conductive materials (nanometer silver wire and gold-coated silver nanowire, the diameter of the nano-silver wire is 27-30nm, the length is 5-16μm, the diameter of the gold-coated silver nanowire is 30-50nm, the length is 5-16μm, and the nano-silver The content of wire is 80%) and the nano-silver ink with 0.14wt% content is coated on the surface of the substrate PET, placed at 100 ° C for drying, after drying, the surface is coated with a protective layer (OC for short), after drying at 100 ° C Place at 175° C. for 5 minutes to cure to obtain a conductive film; print the etching paste on the conductive film with a printing width of 150 μm, place it at 120° C. for 30 minutes, and clean it with water after etching.

[0036] The silver wires in the etching area are etched, but the gold-coated silver nanowires are almost not etched, and the...

PUM

| Property | Measurement | Unit |

|---|---|---|

| length | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com