Method and device for magnetic particle induced laser plasma etching insulating transparent material

A transparent material and plasma technology, applied in laser welding equipment, welding equipment, metal processing equipment, etc., can solve problems such as complex operation, high cost of high-power lasers, thermal cracking of glass, etc., achieve high output frequency, realize processing efficiency, The effect of reducing power requirements

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0034] The present invention will be further described below in conjunction with the accompanying drawings and specific embodiments, but the protection scope of the present invention is not limited thereto.

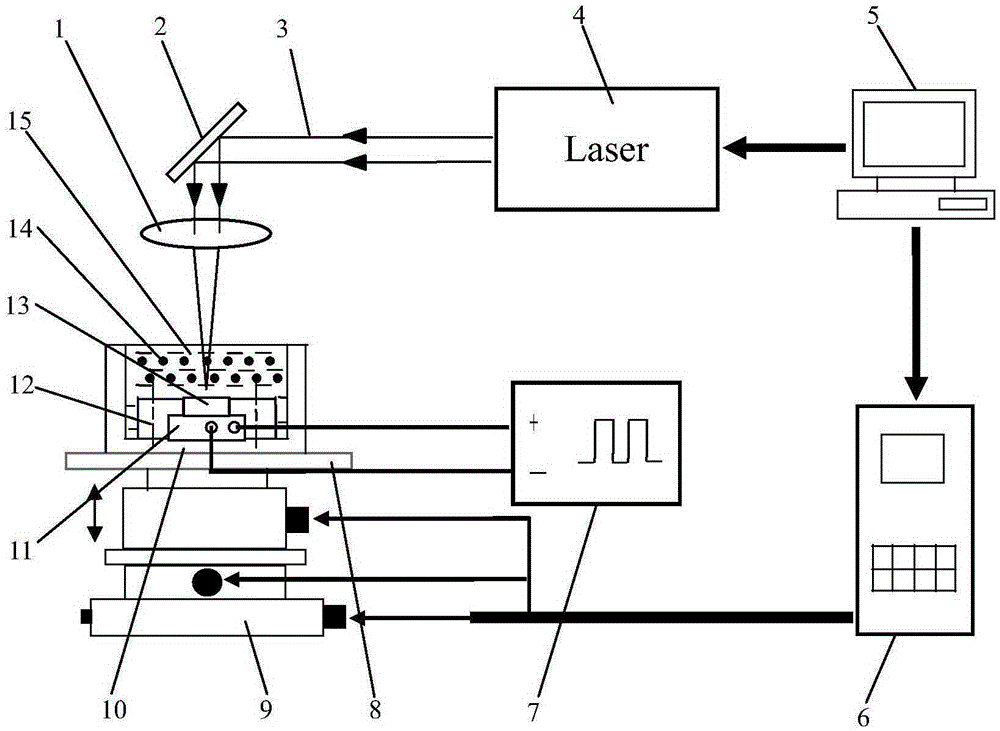

[0035] Such as figure 1 As shown, the device for etching insulating and transparent materials by magnetic particle-induced laser plasma in the present invention includes a laser output device, a beam transmission system, and a laser etching processing system. The laser output device is a nanosecond pulse laser, the wavelength of the output pulse laser is 1064 nanometers, the pulse time is 10 nanoseconds, the frequency is 10-100 Hz, the laser energy is 1 Joule, and the laser spot mode is selected from basement film or multimode. The beam transmission system is located on the laser optical path and includes an adjustable mirror and an adjustable focusing lens. The laser beam emitted by the laser is focused on the glass surface through the beam modulation and transmission sy...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| wavelength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com