Degerming and acarus-killing method for clothes processing equipment and clothes processing equipment

A technology for clothes processing equipment and compressors, which is applied to household clothes dryers, washing devices, textiles, and papermaking, etc. It can solve the problems of poor sterilization and mite removal effects, achieve good sterilization or mite removal effects, and good removal The effect of anti-mite effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

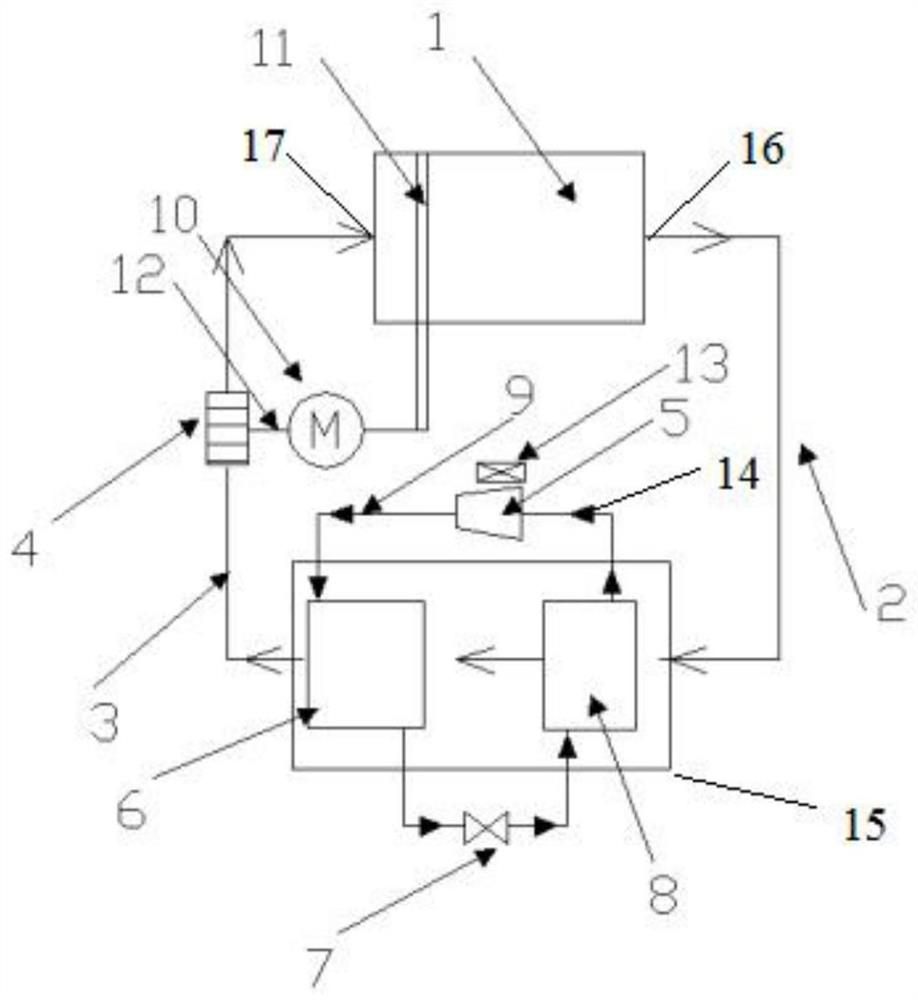

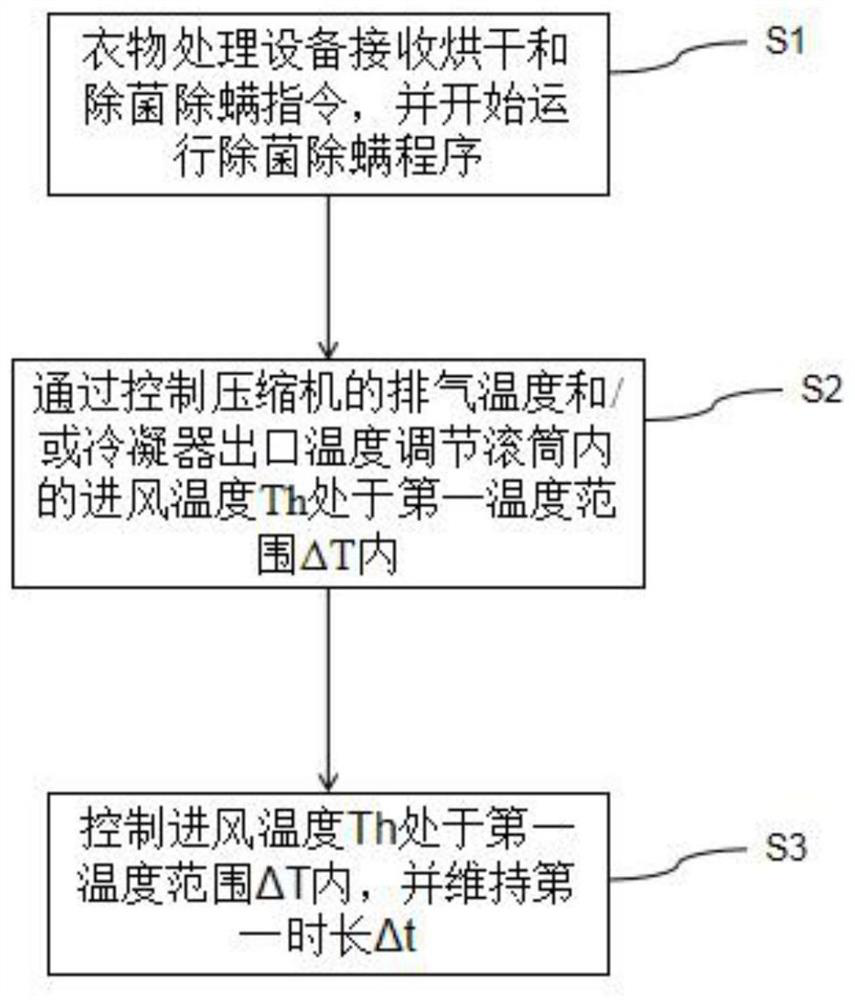

[0064] Such as Figure 1~4 As shown, this embodiment provides a method for eliminating bacteria and mites in clothes treatment equipment by controlling the ratio of on-off time of the cooling fan to control the exhaust temperature of the compressor, which specifically includes the following steps:

[0065] S1. Start-up: the laundry processing equipment receives the drying and sterilization and mite removal instructions, and starts to run the sterilization and mite removal program.

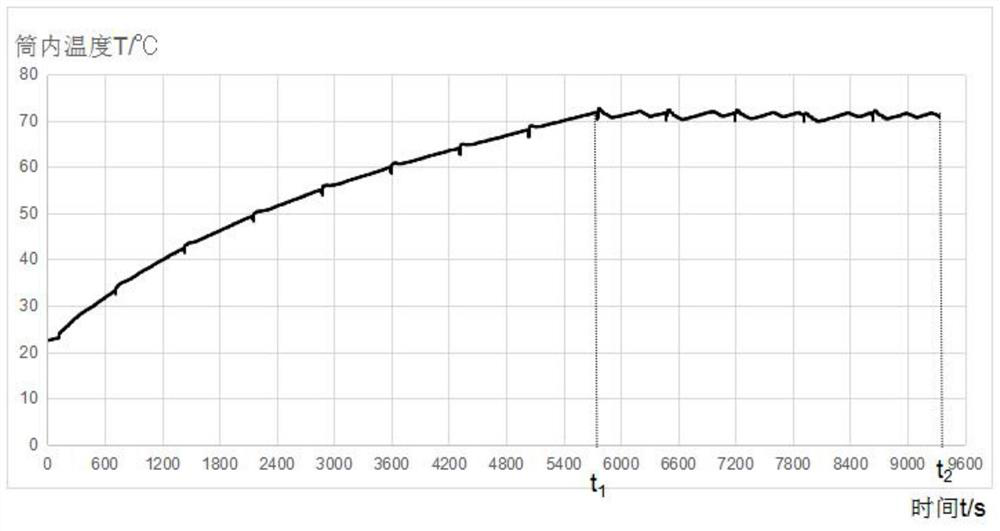

[0066] The motor 10 and the heat pump system 15 are turned on, and the circulating air heated by the heat pump system 15 enters the interior of the drum 1 to dry the clothes inside the drum 1, and the temperature Th of the inlet air in the drum 1 begins to rise, as image 3 As shown, the time period during which the inlet air temperature Th increases is: 0~t1, and t1 is 5400s~6000s.

[0067] S21. Determine whether the discharge temperature Tp of the compressor 5 reaches the second set temperature ...

Embodiment 2

[0075] Such as Figure 1~3 and Figure 5 As shown, this embodiment provides a method for eliminating bacteria and mites in clothes treatment equipment by controlling the frequency of the compressor 5 to control the discharge temperature of the compressor. The difference between this embodiment and Embodiment 1 is:

[0076] Step S22, controlling the air inlet temperature Th in the drum to be in the range of 70-75° C. by controlling the frequency of the compressor.

[0077] When the inlet air temperature Th is close to or greater than 75°C, the compressor discharge temperature can be lowered by reducing the operating frequency of the compressor, and then the inlet air temperature Th in the drum can be lowered to keep Th within the range of 70-75°C. Because the temperature is too high, it will cause damage to the clothes in the drum; when the inlet air temperature Th is close to or lower than 70°C, you can increase the compressor operating frequency to increase the compressor di...

Embodiment 3

[0082] Such as Figure 1~3 and Figure 6As shown, this embodiment provides a method for eliminating bacteria and mites in clothes treatment equipment that controls the exhaust temperature of the compressor by controlling the ratio of on-off time of the cooling fan and the frequency of compressor up-and-down. The difference is that:

[0083] S22. Control the inlet air temperature Th in the drum 1 to be in the range of 70-75° C. by adjusting the time ratio of turning on and off of the cooling fan 13 and increasing the operating frequency of the compressor;

[0084] When the inlet air temperature Th is close to or 75°C, you can turn on the cooling fan and reduce the operating frequency of the compressor to reduce the discharge temperature of the compressor, and then reduce the inlet air temperature Th in the drum to maintain Th at 70-75°C Within the range, the clothes in the drum will not be damaged due to excessive temperature; when the inlet air temperature Th is close to or ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com