Air film building with rail type sliding snow removing structure

An air-film building and track-type technology, which is applied in the field of air-film buildings, energy-saving and environmental-friendly air-film buildings, can solve the problems of affecting the service life of air-film buildings, prone to collapse, and air-film buildings without snow removal structures, etc., so as to ensure firmness performance, improve service life, and improve the effect of use

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

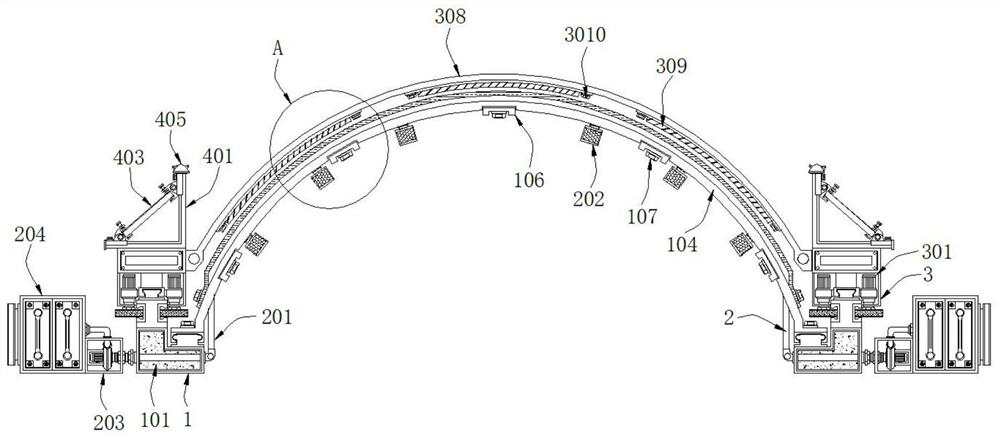

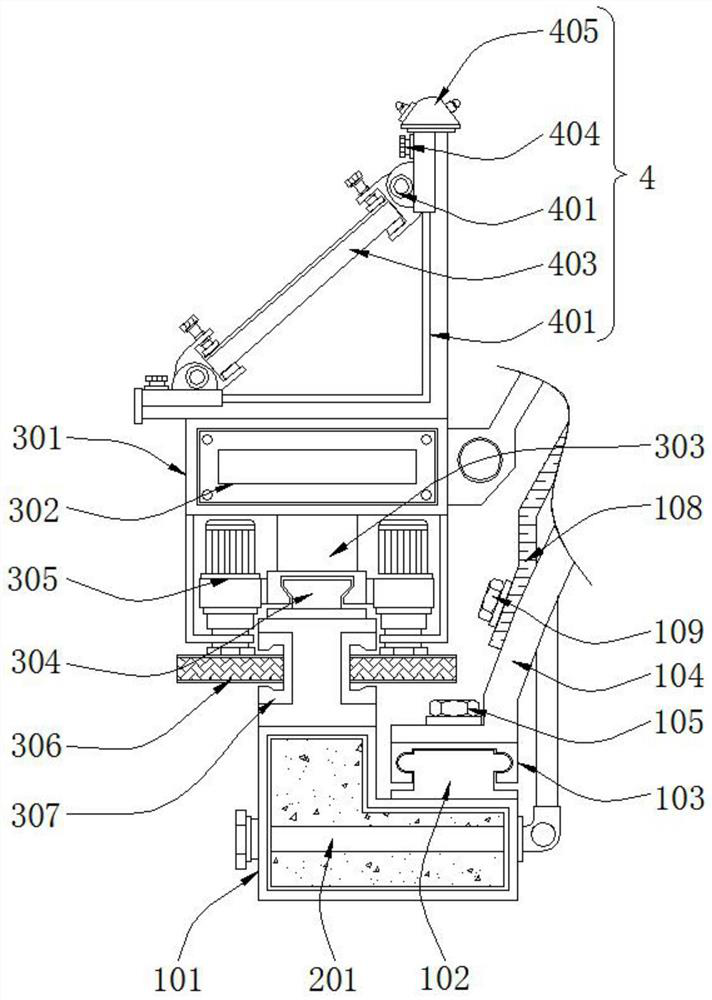

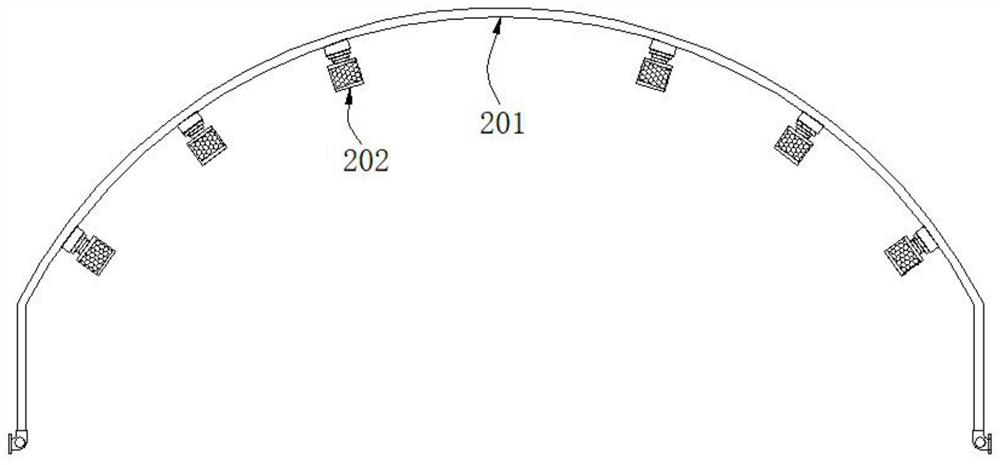

[0029] see Figure 1-7 , a kind of air film building with track-type sliding snow removal structure, including placement assembly 1 and energy collection assembly 4, the middle of placement assembly 1 is provided with ventilation assembly 2, and the outside of placement assembly 1 is provided with snow removal assembly 3, snow removal assembly 3 It includes a fixed frame 301, a battery compartment 302, a limit slider 303, a limit slide 304, a drive motor 305, a drive wheel 306, a drive slot 307, an arc-shaped snow removal beam 308, a flexible scraper 309 and assembly bolts 3010, and fixed The upper part of the inner side of the frame 301 is provided with a battery compartment 302 , the middle part of the inner side of the fixed frame 301 is provided with a limit slider 303 , and the lower end of the limit slider 303 is connected to a limit slide rail 304 , and a drive is provided on both sides of the inner lower part of the fixed frame 301 . The motor 305, and the lower end of...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com