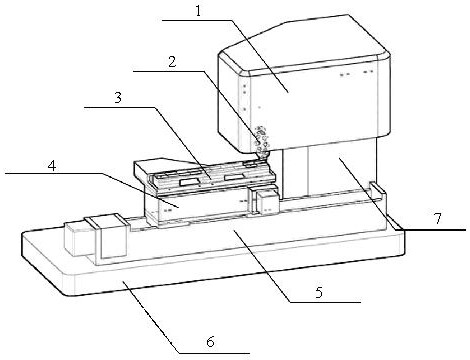

High-flux scratch-reciprocating friction wear test device

A friction and wear test, high-throughput technology, applied in the direction of measuring devices, using mechanical devices, testing wear resistance, etc., can solve the problems of lengthy, cumbersome, and reduced detection efficiency, and achieve high stability and precise control effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

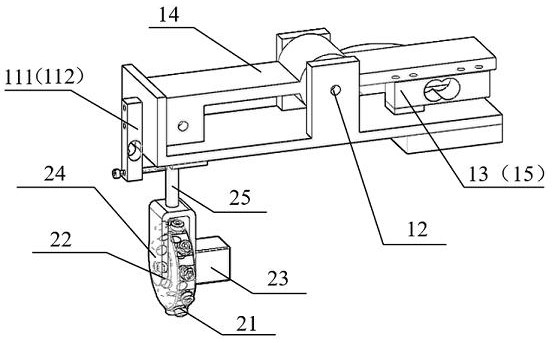

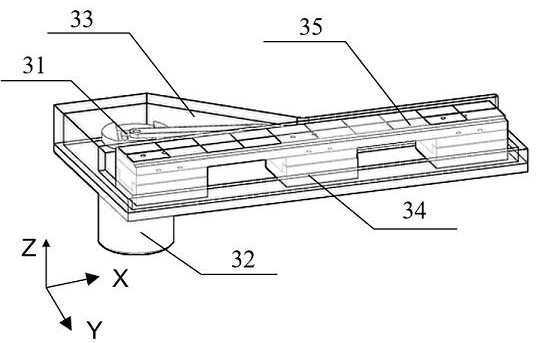

[0038] Example 1 The high-throughput coating scratch (bonding force) is tested. This test is a fixed load test to evaluate the samples with better membrane-base binding force among high-throughput samples. The specific process is as follows:

[0039] The multi-station grinding head disc 24 is equipped with a stylus, and the sample to be tested is fixed on the support plate I35 in the sample holder system 3. By adjusting the sample holder system 3 (X axis) and the sample reciprocating-scribing Tracking platform 4 (Y axis) ensures that the sample reaches the designated position. The position of the loading rod 25 is adjusted by the driving motor V15, so that the sample is in contact with the stylus, and then a fixed load is applied by the loading force sensor 13 and the driving motor V15. The sample reciprocating-scratch platform 4 moves along the reciprocating sliding track 53 of the sample displacement platform 5 along the X-axis at a uniform speed in one direction, so that s...

Embodiment 2

[0040] Example 2 Test the scratch (bonding force) of the high-throughput coating. This test is a uniform loading test, and the film-base binding force of the sample is tested. The specific process is as follows:

[0041] The multi-station grinding head disk 24 is equipped with a stylus, and the sample to be tested is fixed in the sample holder system 3. By adjusting the sample holder system 3 (X axis) and the sample reciprocating-scratch platform 4 (Y axis) to ensure that the sample arrives at the specified position. The position of the loading rod 25 is adjusted through the driving motor V15, so that the sample is in contact with the stylus, and then a uniform load is applied through the loading force sensor 13 and the driving motor V15. At the same time, the sample reciprocating-scratch platform 4 moves at a uniform speed along the X-axis along the reciprocating sliding track 53 of the sample displacement platform 5, and the setting end load is proportional to the scratch d...

Embodiment 3

[0042] Example 3 The friction and wear of high-throughput coatings is tested, this test is a fixed load test, and the friction and wear behavior of high-throughput samples is evaluated. The specific process is as follows:

[0043] The contact head 21 corresponding to the station on the multi-station grinding head disk 24 is a friction pair module (the friction pair can be a ball or a pin), and the sample to be tested is fixed in the sample holder system 3. By adjusting the sample holder system 3 (X-axis) and sample reciprocating-scratch platform 4 (Y-axis) to ensure that the sample reaches the designated position. The position of the loading rod 25 is adjusted through the driving motor V15, so that the sample is in contact with the friction pair, and then a fixed load is applied through the loading force sensor 13 and the driving motor V15. The sample reciprocating-scratch platform 4 reciprocates along the X-axis along the reciprocating sliding track 53 of the sample displace...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com