Device system and method for staged water supply and cascade recycling of wet cooling unit

A technology for water supply systems and units, applied in separation methods, boiler cleaning devices, chemical instruments and methods, etc., can solve the problems of unsuitability for large-scale popularization, high system investment and high maintenance costs, and achieve obvious economic and environmental benefits. The effect of low operation and management costs and reduced demand

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

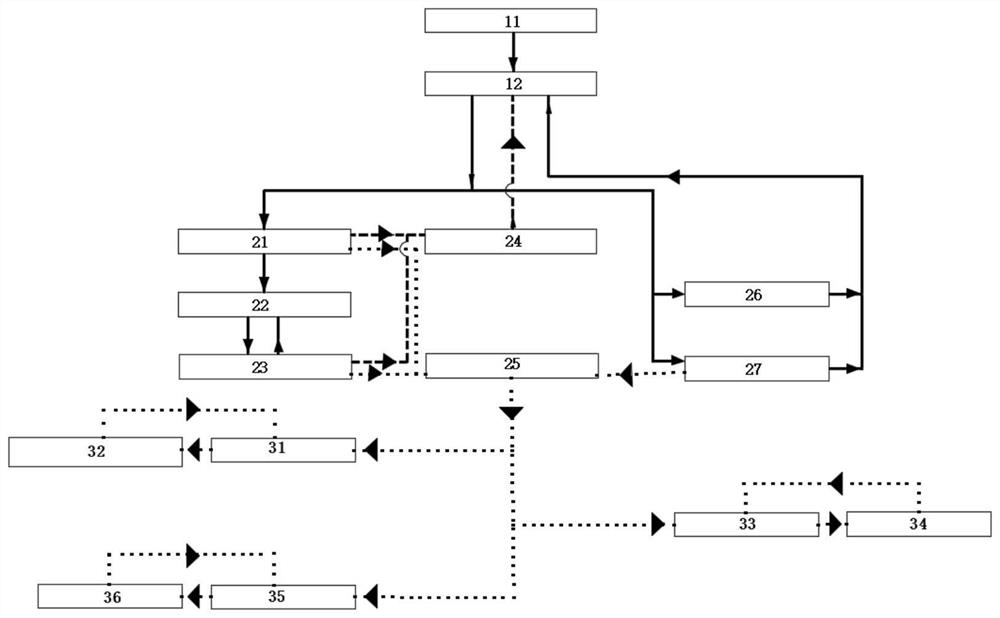

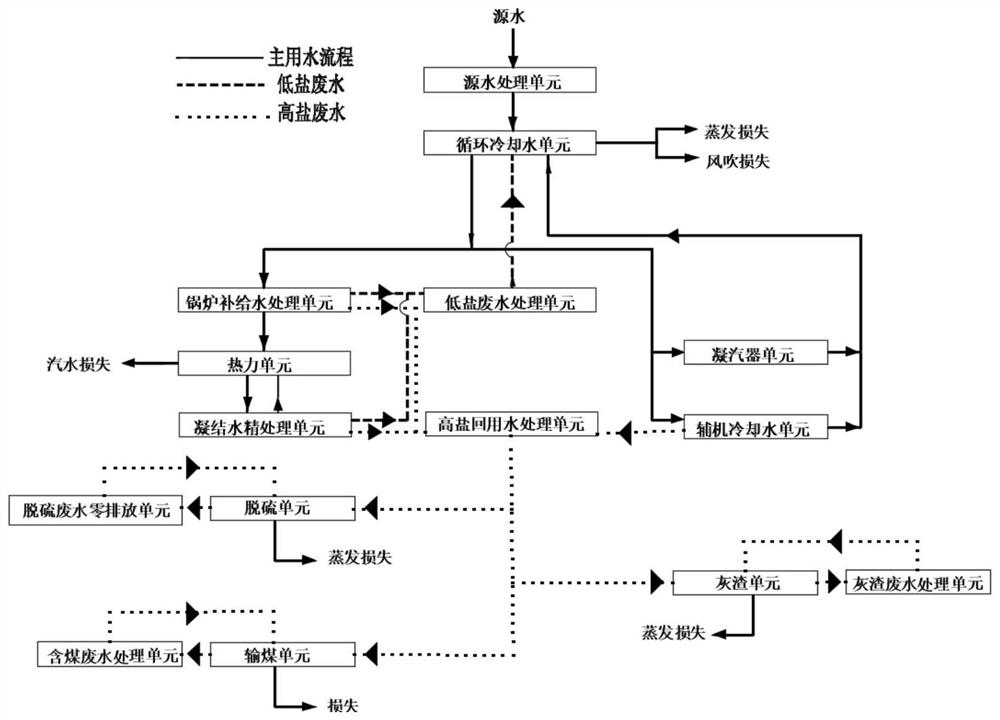

[0113] This embodiment provides a device system for cascaded reuse of wet-cooling unit graded water supply. cycle connected.

[0114] The primary water supply system includes a source water treatment unit and a circulating cooling water unit connected in sequence, and the circulating cooling water unit is connected to the boiler feed water treatment unit in the secondary water supply system.

[0115] The secondary water supply system includes a boiler feed water treatment unit, a thermal unit, a condensate fine treatment unit, a low-salt wastewater treatment unit, a high-salt reuse water treatment unit, a condenser unit and an auxiliary cooling water unit. The low-salt wastewater outlet pipe of the boiler feed water treatment unit and the low-salt wastewater outlet pipe of the condensate polishing unit are connected to the low-salt wastewater treatment unit, and the outlet pipe of the low-salt wastewater treatment unit is connected to the circulating cooling water unit; The h...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com