Front axle assembly of automatic driving test target vehicle carrying platform

A technology for testing objects and carrying platforms, applied in the field of front axle assembly, which can solve problems such as inability to complete vehicle emergency braking, collision, rolling, difficult to meet braking performance requirements, and structural failure to arrange braking systems, etc., to achieve good Steering lightness, improved straight-line driving ability and returning ability, and better braking thermal stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

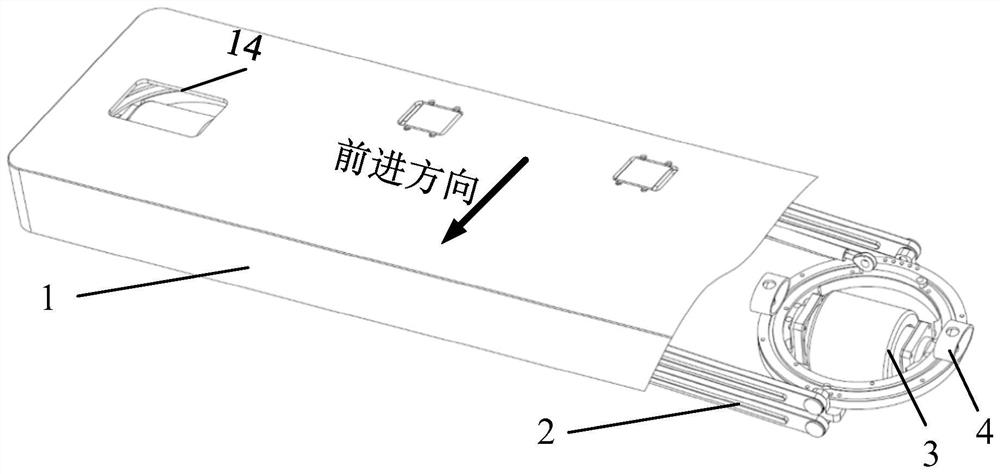

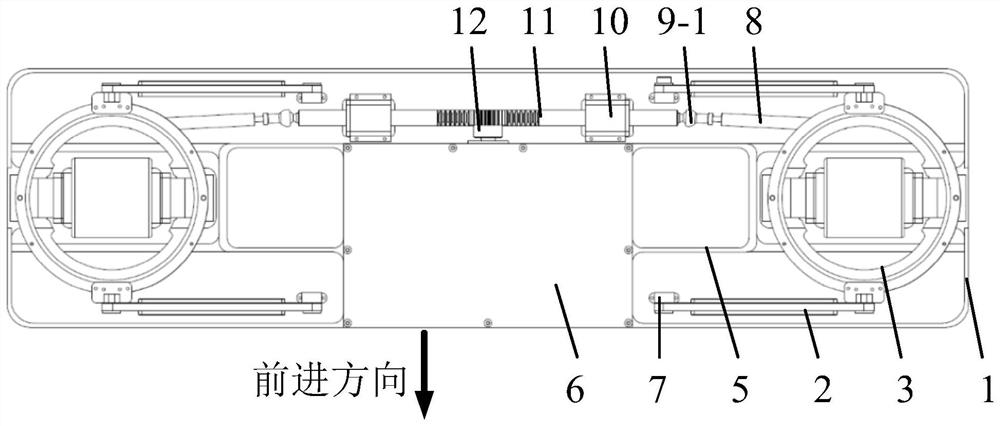

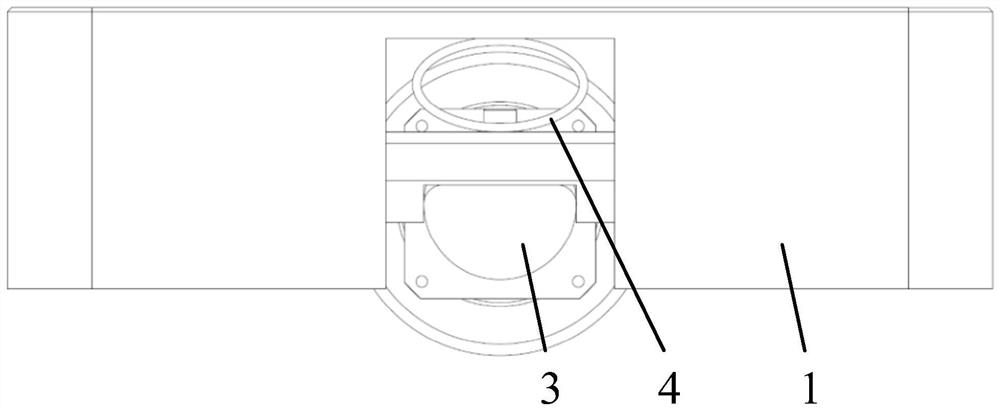

[0038] A front axle assembly of a self-driving test target vehicle carrying platform, such as Figure 1~3 As shown, the housing 1, the steering assembly, the two wheel assemblies 3 and the two suspension assemblies, each assembly is embedded in the housing by modularization, the structure height is extremely low, and it can be matched with other actuators and the target vehicle to meet the For the strict requirements of emergency braking, high-speed collision and crushing and other dangerous test conditions of automatic driving, the rack and pinion mechanism is used as the power source of the steering system, the suspension system is a parallel double swing arm mechanism, and the hub electromagnetic braking system realizes Flat, compact, integrated front axle configuration.

[0039] In this embodiment, the shell 1 is integrally formed by high-strength aluminum alloy, and the inner cavity is provided with a ribbed box 5. The thickness of the shell 1 and the ribbed box 5 is desi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com