Terminal crimping machine for branching

A terminal crimping machine and branching technology, which is applied in the direction of connection, line/collector parts, electrical components, etc., can solve the problem of easy arching of the cable, and achieve the advantages of simple and labor-saving operation, good effect, and ingenious structural design Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

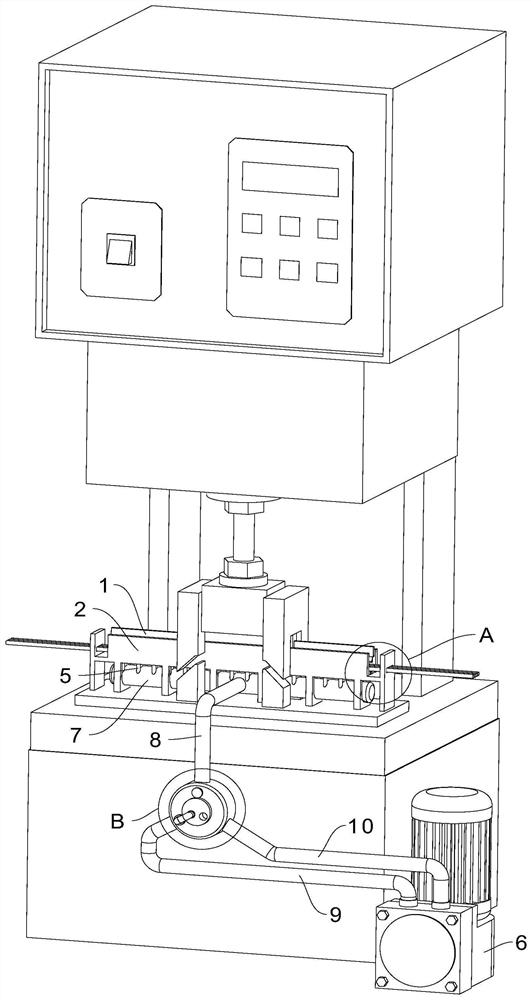

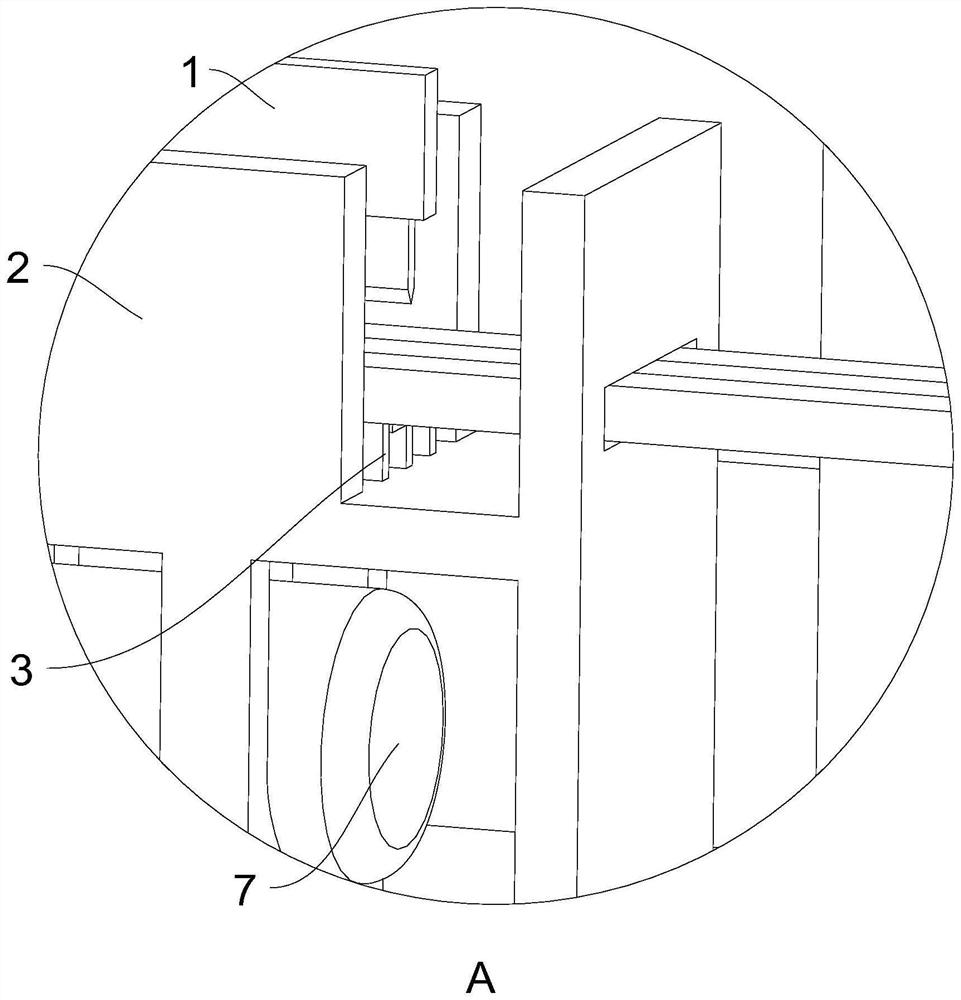

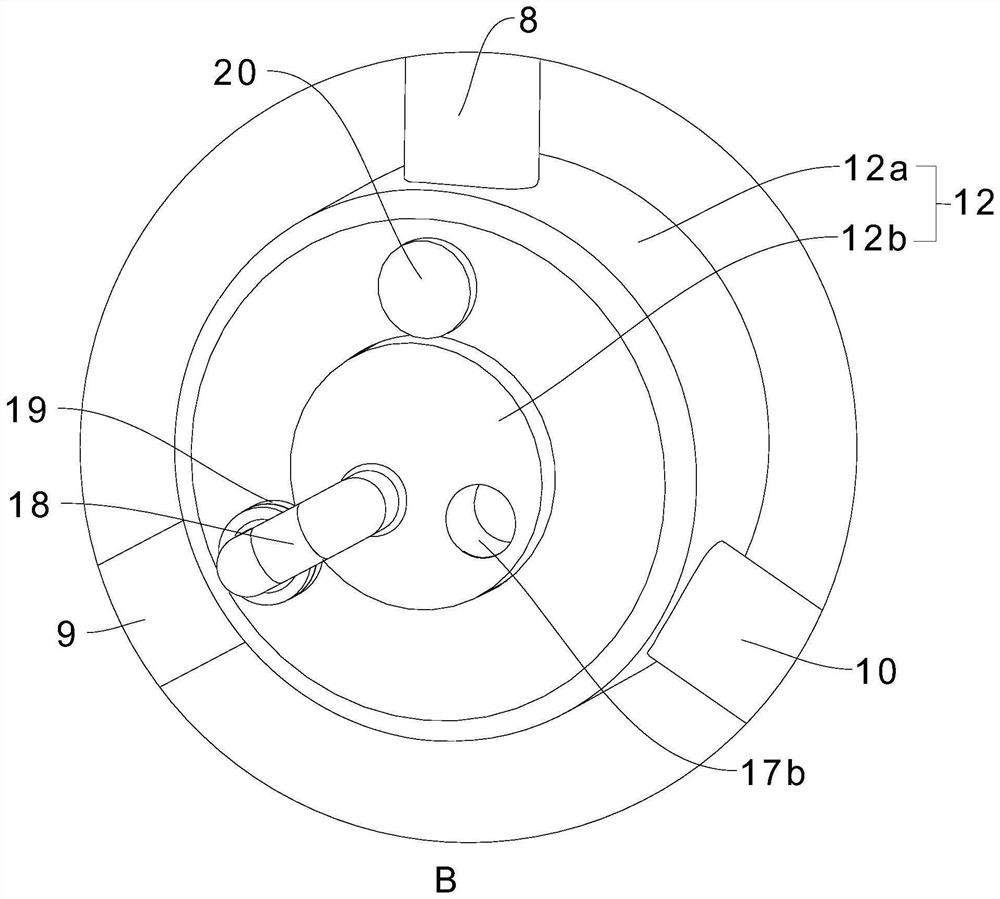

[0040] A terminal crimping machine for branching provided by the present invention, such as Figure 1 to Figure 8 As shown, the upper mold 1 and the lower mold 2 that the vertical movable pipe is arranged below the upper mold 1 are included, the longitudinal section of the lower mold 2 is U-shaped, and the opposite of the upper mold 1 and the lower mold 2 A plurality of slitting blades 3 are arranged in a staggered manner corresponding to the surface, and the lower mold 2 is uniformly provided with a plurality of air holes 4 and is connected with a plurality of branch pipes 5 communicating with the air holes 4, and also includes an air extraction device 6. The suction device 6 communicates with the branch pipe 5 .

[0041] Working process: the cable is pre-passed from the clamping mechanism on one side of the lower mold 2 to the clamping mechanism on the other side of the lower mold 2, and the two sides of the U-shaped lower mold 2 can carry out the wiring A certain degree of...

Embodiment 2

[0053] A terminal crimping machine for branching, such as Figure 9 As shown, different from the structure of the conversion assembly 12 in Embodiment 1, it also includes a first conversion tube 21 and a second conversion tube 22, and the first conversion tube 21 and the second conversion tube 22 are connected to the communication tube 8 The first conversion pipe 21 and the second conversion pipe 22 are provided with a control valve 23, the first conversion pipe 21 is screwed to the outlet pipe 10, and the second conversion pipe 22 is connected to the second conversion pipe 22. The air intake pipe 9 is threaded.

[0054]Suction function conversion: When the air suction device 6 exerts its suction function to make the cable and the lower mold 2 fit together, the first conversion pipe 21 is separated from the air outlet pipe 10, and will be installed on the first conversion pipe 21 The control valve 23 of the second conversion pipe 22 is closed, and the second conversion pipe 2...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap