Anti-short-circuit high-voltage circuit board and manufacturing method thereof

A manufacturing method and high-voltage technology, applied in the field of PCB manufacturing, can solve the problems of reduced wiring density, increased cost, and increased product volume, and achieved the effect of preventing internal short circuits and improving withstand voltage capability.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

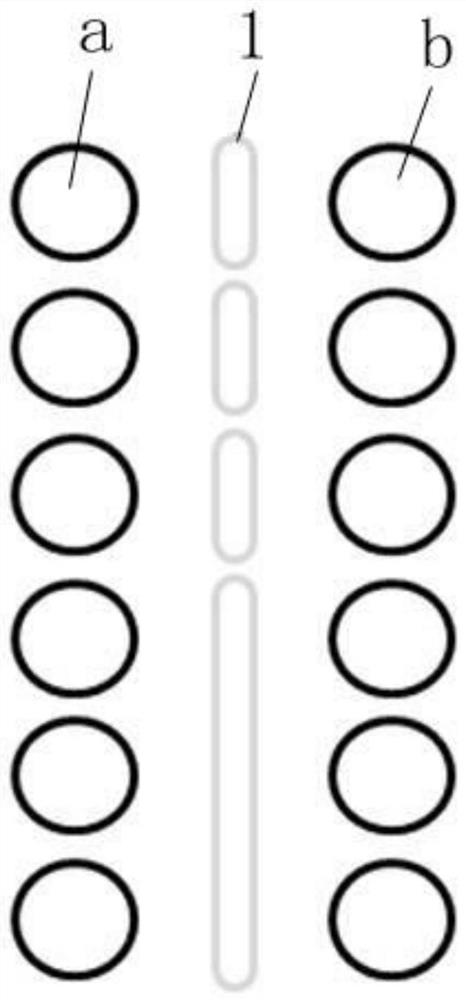

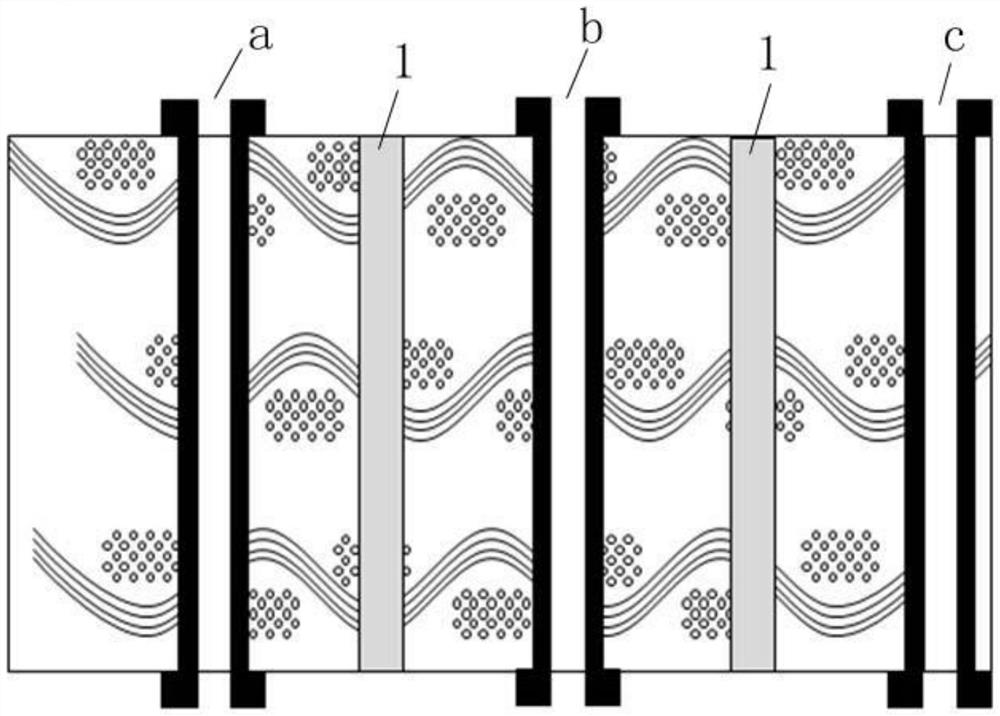

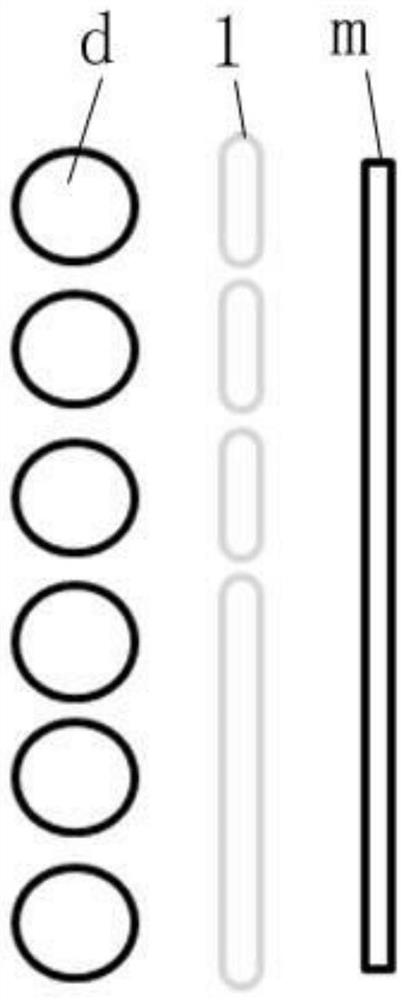

[0025] A method for manufacturing a short-circuit-proof high-voltage circuit board, comprising: between through holes with voltage differences on the high-voltage circuit board ( figure 1 Between the through hole a and the through hole b; figure 2 between through hole a and through hole b, through hole b and through hole c), between the through hole and the line where there is a voltage difference ( image 3 Between the through hole d and the line m; Figure 4 Make isolation holes between through hole d and line m, through hole e and line n, line m and through hole e).

[0026] In this embodiment, the isolation hole is a slotted hole 1 with a non-conductive inner wall processed by milling; the length of the slotted hole 1 is equal to or greater than the diameter of the corresponding through hole; The projected area on the through hole or line with which there is a voltage difference is completely shielded. The base material of high-voltage circuit boards contains glass fib...

Embodiment 2

[0028] The difference between this embodiment and Embodiment 1 is that the isolation hole is one drilled or several continuous non-perforated holes, and the continuous several non-perforated holes are tangent or intersected to form a string of non-perforated holes. The diameter of the non-through hole is equal to or greater than the diameter of the corresponding through hole. If the non-through hole string is used, the length of the non-through hole string is equal to or greater than the diameter of the corresponding through hole; and the setting position satisfies: the corresponding through hole is placed on another The projected area on a through hole or line with which there is a voltage difference is completely shielded. Such as Figure 5~Figure 8 shown in Figure 5 Among them, the length of the uppermost non-through hole 2 is longer than the diameter of the corresponding topmost through hole A and through hole B, and the non-through hole 2 completely covers the projectio...

Embodiment 3

[0030] Based on the manufacturing method of the short-circuit-proof high-voltage circuit board described in Embodiment 1 and Embodiment 2, this embodiment provides a short-circuit-proof high-voltage circuit board. There is an isolation hole between the through hole and the line where there is a voltage difference. The isolation hole is a non-conductive slot on the inner wall. The length of the slot is equal to or greater than the diameter of the corresponding through hole; The projected area of is completely covered. Or the isolation hole is one or several consecutive non-perforated holes, and the continuous several non-perforated holes are tangent or intersected to form a series of non-perforated holes; the diameter of the non-perforated holes is equal to or greater than the diameter of the corresponding through-holes. The non-through hole string, the length of the non-through hole string is equal to or greater than the diameter of the corresponding through hole; and the s...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com