In-situ activated geopolymer plugging agent and preparation method thereof

A technology of geopolymer and plugging agent, which is applied in drilling compositions, chemical instruments and methods, and earthwork drilling and mining, and can solve the problems of large loss of plugging agent

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

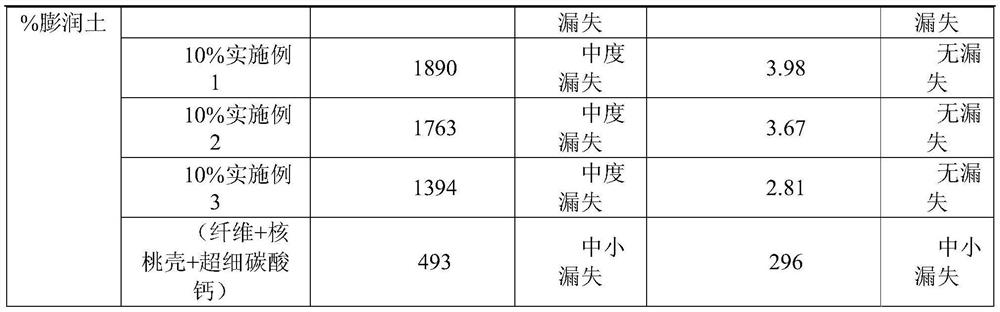

Embodiment 1

[0055] 1) Preparation of pre-embedded activator: (1) Add 300g of flake sodium hydroxide, 200g of dry powdered water glass (modulus 2.0), 100g of sodium fluorosilicate and 1200g of deionized water in the autoclave, and the system Increase the temperature to 60°C, increase the stirring speed to 2000rpm, and alkalize for 30 minutes; (2) Add 1200g chitosan and 1000g deionized water to the above reactor in sequence, raise the system temperature to 150°C, and increase the stirring speed Reduce to 300rpm, continue to react for 30min; (3) after the reaction is over, cool, vacuum filter three times, collect the corresponding microspheres, wash the surface of the microspheres with deionized water three times, transfer to a rotary evaporator, remove the remaining solvent, and obtain Pre-embedded activators.

[0056] 2) Preparation of in-situ activated geopolymer plugging agent: (1) Add 2200g metakaolin, 1800g red mud, and 2100g pozzolan powder in sequence to a high-temperature and high-p...

Embodiment 2

[0058] 1) Preparation of pre-embedded activator: (1) Add 400g of flake sodium hydroxide, 250g of dry powdered water glass (modulus 2.5), 125g of sodium fluorosilicate and 1350g of deionized water in the autoclave, and the system Increase the temperature to 70°C, increase the stirring speed to 2000rpm, and alkalinize for 40 minutes; (2) Add 1350g chitosan and 1250g deionized water to the above reactor in sequence, raise the system temperature to 165°C, and increase the stirring speed Reduce to 300rpm, continue to react for 40min; (3) After the reaction is over, cool, vacuum filter three times, collect the corresponding microspheres, wash the surface of the microspheres with deionized water three times, transfer to a rotary evaporator, remove the remaining solvent, and obtain Pre-embedded activators.

[0059] 2) Preparation of in-situ activated geopolymer plugging agent: (1) Add 2350g metakaolin, 1900g red mud, and 2350g pozzolan powder in sequence to a high-temperature and high...

Embodiment 3

[0061] 1) Preparation of pre-embedded activator: (1) Add 500g of flake sodium hydroxide, 300g of dry powdered water glass (modulus 3.0), 150g of sodium fluorosilicate and 1500g of deionized water in the autoclave, and the system Increase the temperature to 80°C, increase the stirring speed to 2000rpm, and alkalinize for 50 minutes; (2) Add 1500g chitosan and 1500g deionized water to the above reactor in sequence, raise the system temperature to 180°C, and increase the stirring speed Reduce to 300rpm, continue to react for 50min; (3) After the reaction is over, cool, vacuum filter three times, collect the corresponding microspheres, wash the surface of the microspheres with deionized water three times, transfer to a rotary evaporator, remove the remaining solvent, and obtain Pre-embedded activator.

[0062] 2) Preparation of in-situ activated geopolymer plugging agent: (1) Add 2500g metakaolin, 2000g red mud, and 2600g pozzolan powder in sequence to a high-temperature and high-...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com