Double-process electric furnace waste heat utilization system with stable steam parameters

A technology with steam parameters and two processes, applied in the field of waste heat recovery devices, can solve the problems of difficulty in stabilizing the steam inlet parameters of the turbine, limited smelting characteristics of electric furnaces, hidden dangers of pipe bursting on the heating surface, etc., to achieve stable output, reduce initial investment, and improve The effect of power generation efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0015] The present invention will be further described below in conjunction with the accompanying drawings.

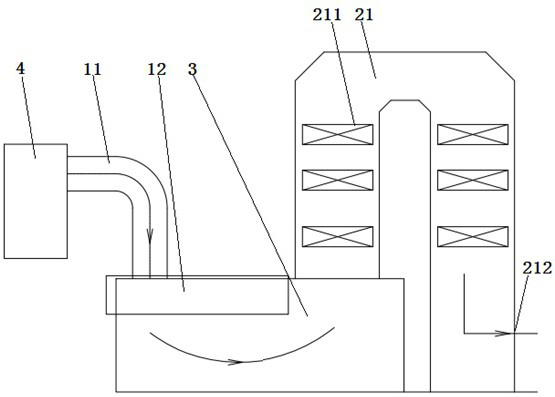

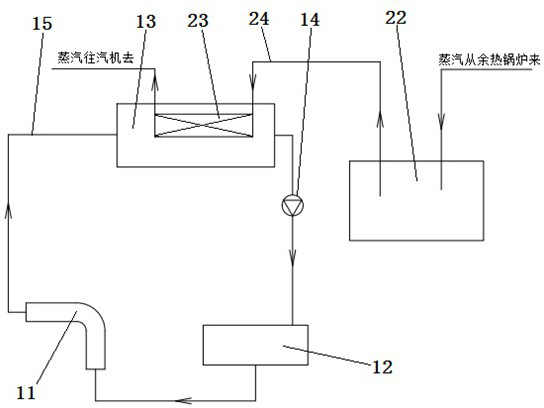

[0016] Such as figure 1 , 2 As shown, a dual-process electric furnace waste heat utilization system with stable steam parameters includes a heat transfer oil working medium process and a steam working medium process. 12 and the heat transfer oil storage tank 13 arranged on the heat transfer oil flue 11 and the heat transfer oil furnace top 12, the heat transfer oil flue 11, the heat transfer oil furnace top 12 and the heat transfer oil storage tank 13 are sequentially connected through the heat transfer oil pipe 15 to realize the heat transfer oil in the three Circulation in the structure; the steam working medium process includes a waste heat boiler 21, a heat accumulator 22 and a superheater 23 connected in sequence through a steam pipeline 24, and the superheater 23 is placed inside the heat transfer oil storage tank 13; The heat transfer oil flue 11 of the heat t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com