Method for predicting phase structure of Al-series high-entropy alloy based on Md-delta

A high-entropy alloy and phase structure technology, applied in testing metal structure, testing metal, material inspection products, etc., can solve problems such as poor applicability, and achieve the effect of reducing preparation cost, avoiding waste and improving efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

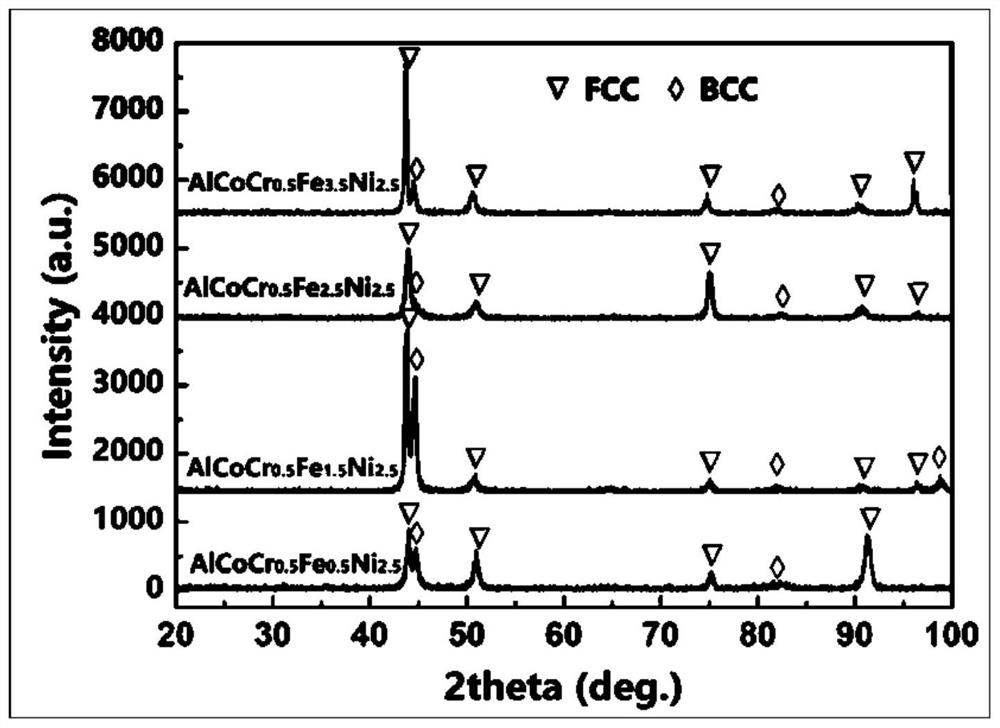

[0024] A method for predicting the phase structure of Al-based high-entropy alloys based on Md-δ, specifically for the analysis of high-entropy alloys AlCoCr with different Fe contents 0.5 Fe x Ni 2.5 The phase composition of , its steps are:

[0025] (1) Al-based target high-entropy alloy is AlCoCr 0.5 Fe x Ni 2.5 (x=0.5, 1.5, 2.5, 3.5), by In the formula, xi is the atomic percentage of the i component, (Md)i represents the Md value of the i component, and the calculation of the atomic radius difference is as follows:

[0026]

[0027] Where: δ r is the atomic radius difference parameter, is the weighted average atomic radius of all components, r i is the atomic radius of component i, c i is the atomic fraction of component i. Calculation available: AlCoCr 0.5 Fe 0.5 Ni 2.5 of δ r =5.580%; AlCoCr0.5Fe1.5Ni2.5 δ r =5.276%; AlCoCr0.5Fe2.5Ni2.5 δ r =5.009%; AlCoCr0.5Fe3.5Ni2.5 δ r = 4.774%;

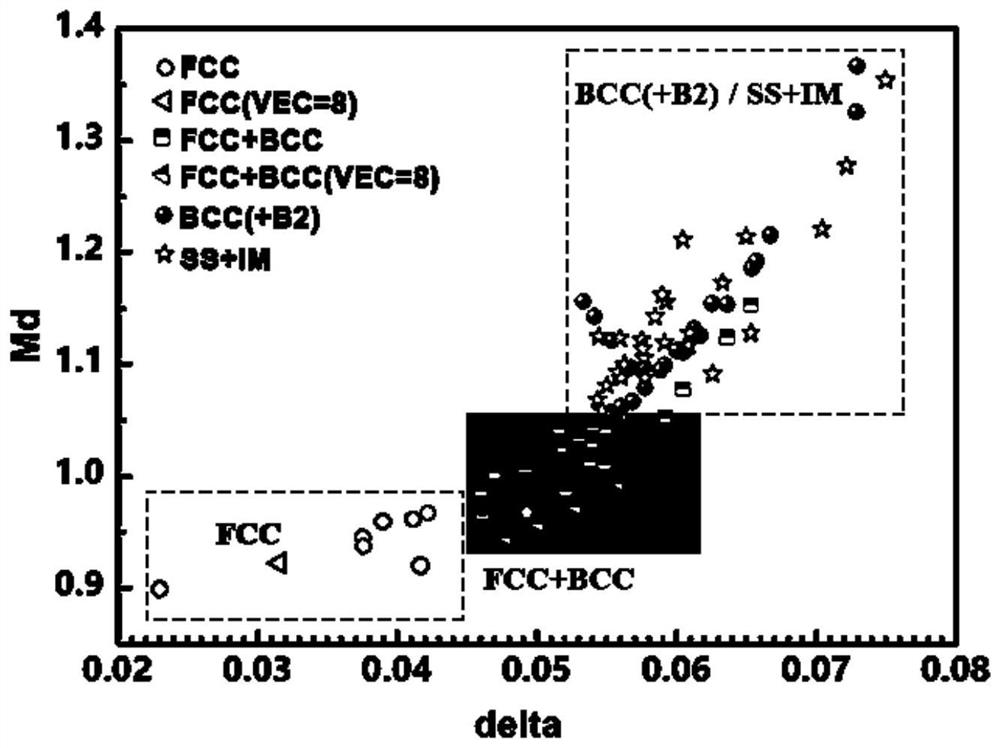

[0028] (2) According to the relationship between Md-δ an...

Embodiment 2

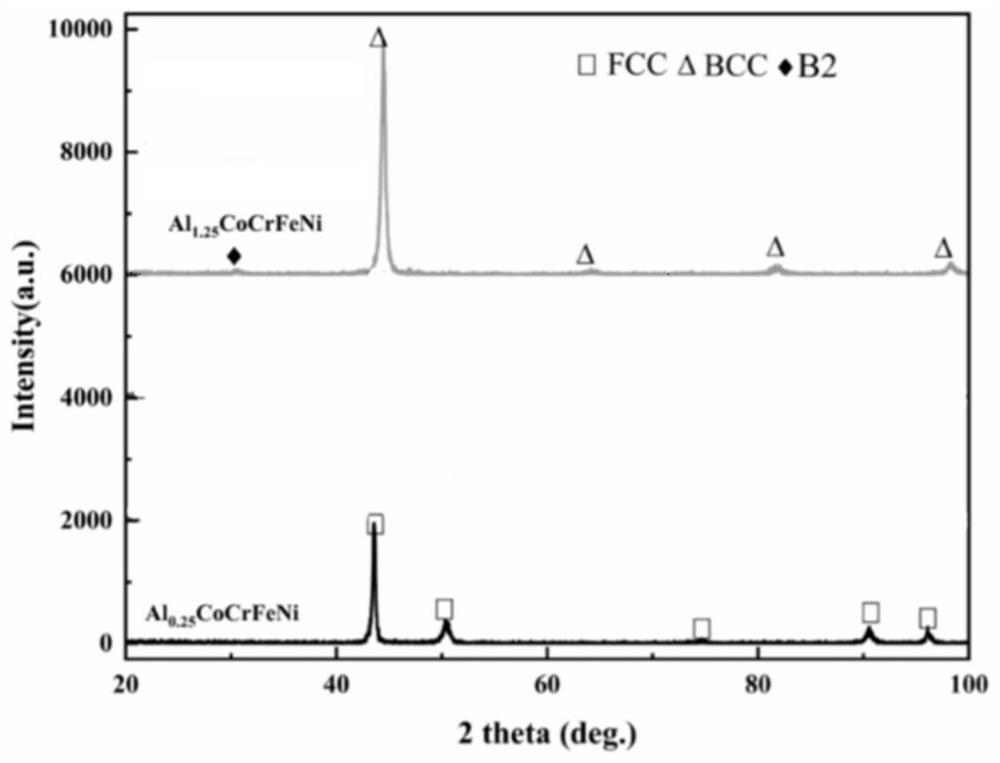

[0032] A method for predicting the phase structure of Al-based high-entropy alloys based on Md-δ, specifically for the analysis of high-entropy alloys with different Al contents x The phase composition of CoCrFeNi (x=0.25, 1.25), its steps are:

[0033] (1) Al-based target high-entropy alloy is Al x CoCrFeNi (x=0.25, 1.25), can be calculated by the formula as described in embodiment 1: Al0.25CoCrFeNi δ r =3.477%; Al1.25CoCrFeNi δ r = 6.116%;

[0034] (2) According to the relationship between Md-δ and phase structure, Al can be predicted 0.25 The CoCrFeNi alloy has an FCC phase structure in the as-cast state, and the Al 1.25 CoCrFeNi alloy forms an ordered structure or forms an intermetallic compound in the as-cast state;

[0035] (3) According to the phase structure and expression of Al-based target high-entropy alloys, the atomic percentages of each component were obtained and converted into weight percentages before alloying and smelting. Vacuum arc melting methods ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com