Ciprofloxacin hydrochloride suppository and preparation method thereof

A technology for ciprofloxacin hydrochloride and suppositories, which is applied in the field of ciprofloxacin hydrochloride suppositories and its preparation, can solve the problems of many types of substrates and low bioavailability of ciprofloxacin hydrochloride suppositories, and achieve simple composition and irritating small effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

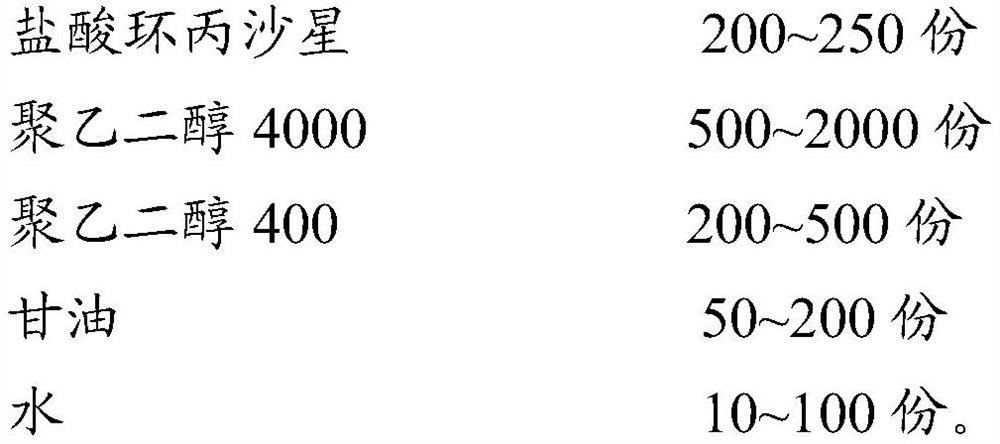

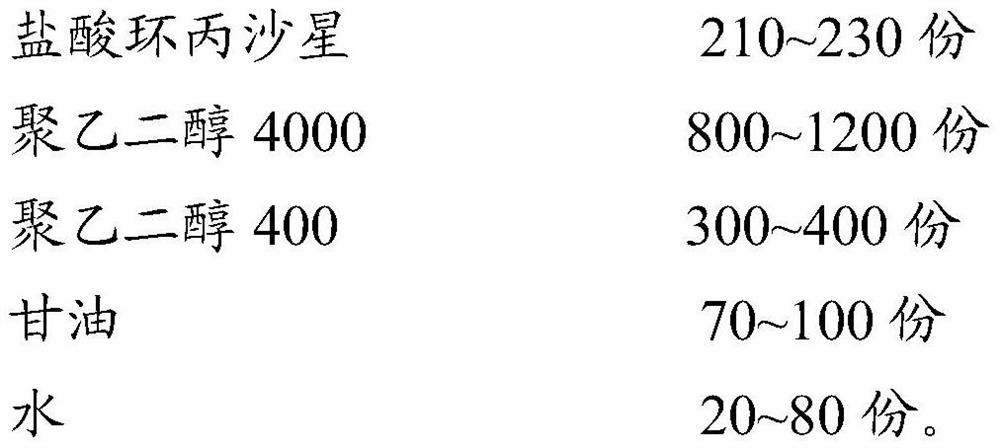

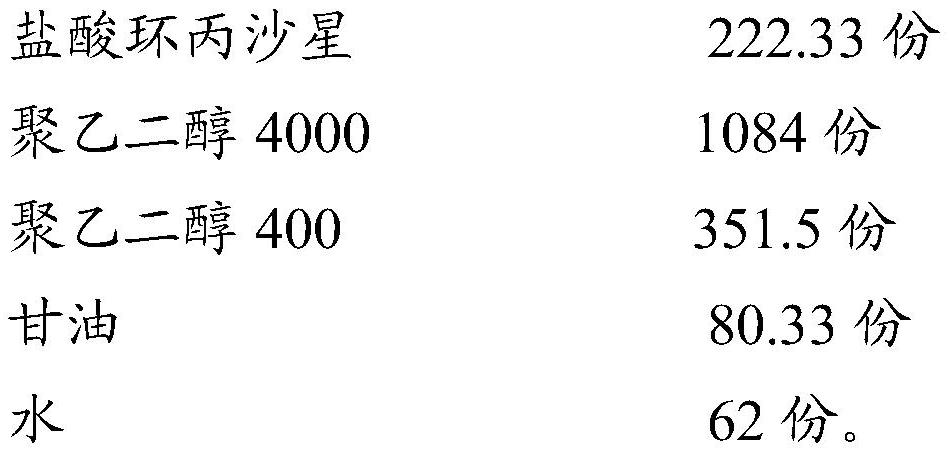

[0029] (1) Prescription

[0030] Table 1 Ciprofloxacin Hydrochloride Suppository Prescription

[0031] Raw materials Dosage for 1000 capsules (g) pre-processing Ciprofloxacin Hydrochloride 222.33 N / A polyethylene glycol 4000 1084 200 mesh filter after melting polyethylene glycol 400 351.5 200 mesh filter glycerin 80.33 200 mesh filter purified water 62 N / A

[0032] (2) Preparation process

[0033] Add polyethylene glycol 4000 and polyethylene glycol 400 into the matrix tank, heat at 80±5°C, and after most of the solid matrix melts, start stirring to completely melt the solid matrix at a stirring speed of 1000r / min; then add glycerin, Purified water, continue stirring for 15-20 minutes. Add the prescribed amount of ciprofloxacin hydrochloride, the main stirring blade is 30-35r / min, and the rapid stirring is 2800-3000r / min for 20 minutes. Vacuumize the main tank to a vacuum degree of -0.06Pa; start stirring; stir for 15...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com