Lithium battery rapid processing and welding device

A welding device and lithium battery technology, applied in lithium batteries, welding equipment, welding equipment, etc., can solve the problems of welding slag scalding workers, prolonging the processing time of lithium batteries, reducing the processing efficiency of lithium batteries, etc., and achieving the effect of increasing processing efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

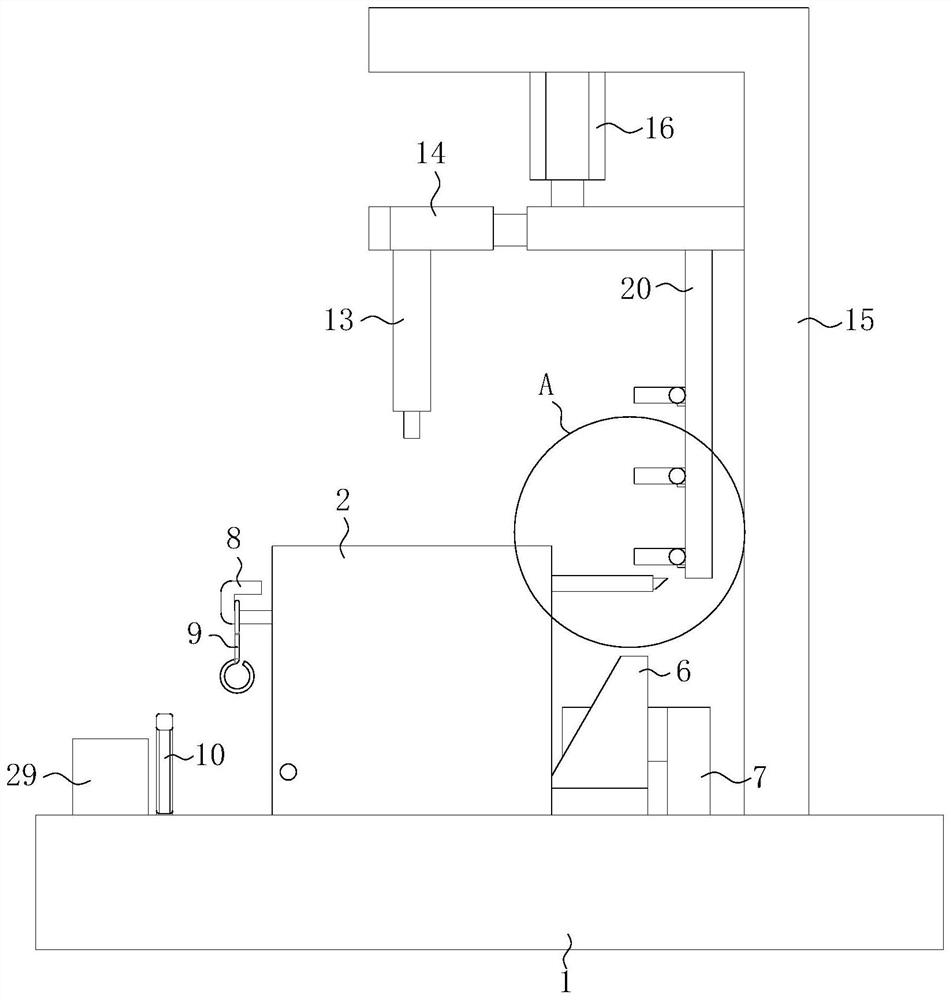

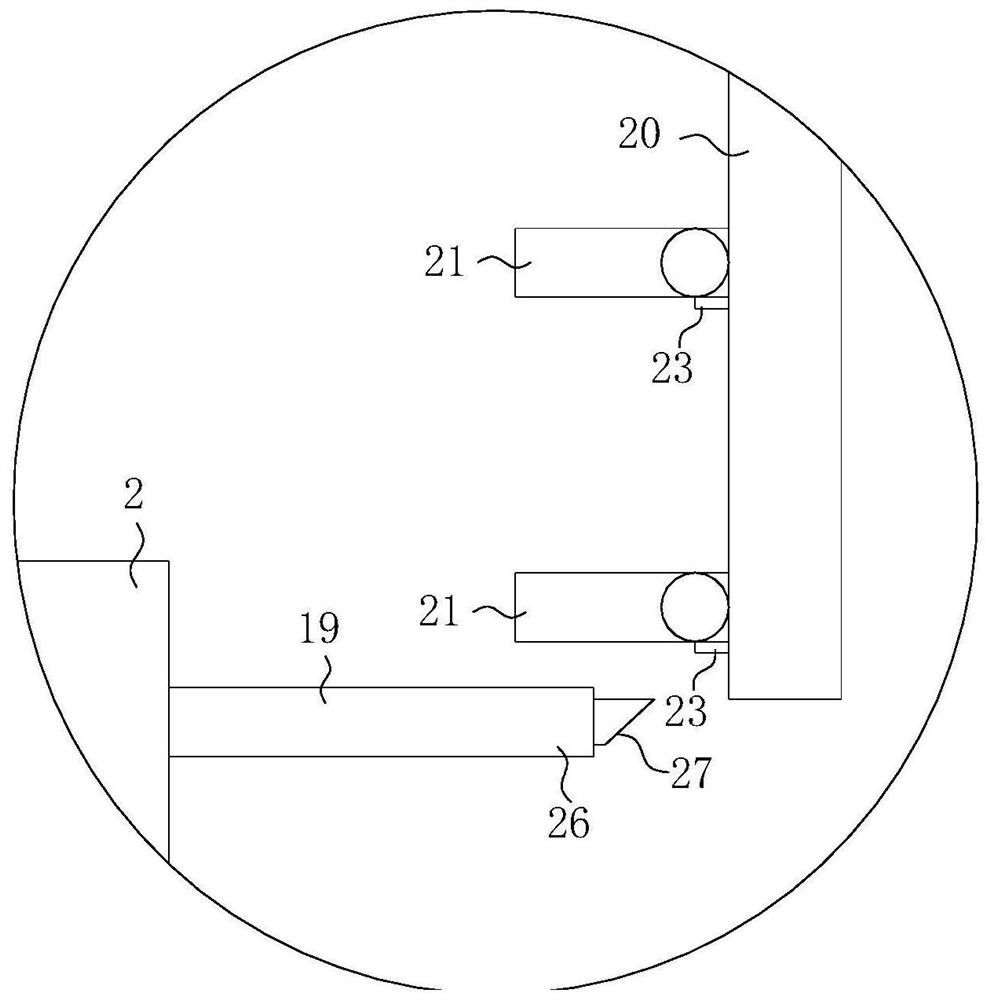

[0031] see figure 1 -9, a lithium battery rapid processing and welding device of the present invention includes a bottom plate 1, a U-shaped frame 2 is slidably connected to the top of the bottom plate 1, and a U-shaped bearing plate is jointly rotatably connected to the left and right inner walls of the U-shaped frame 2 3. A shielding plate 4 is rotatably connected to the top of the front side of the U-shaped carrier plate 3, and a first torsion spring 5 is sleeved on the rotating shaft of the shielding plate 4; The moving linear drive mechanism, the top of the bottom plate 1 is provided with a welding mechanism, and the top of the bottom plate 1 is also provided with a linkage mechanism, which drives the U-shaped carrying plate 3 and the shielding plate 4 under the linkage of the linear drive mechanism Turn over discharge.

[0032]When the above scheme is put into practical application, the lithium battery is placed on the U-shaped carrier plate 3, so that the front and rea...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com