Titanium black modified degradable plastic and production system

A technology for degrading plastics and titanium dioxide, applied in grain processing and other directions, can solve the problems of relatively large impact on plastic quality, unsatisfactory mixing uniformity, and cost reduction, and achieve the effect of improving the effect of extrusion and fusion

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

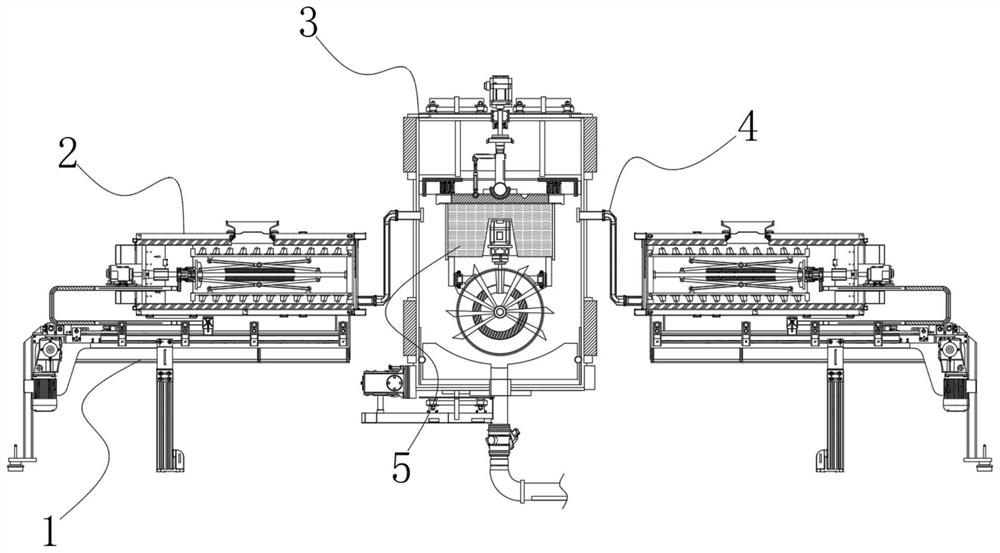

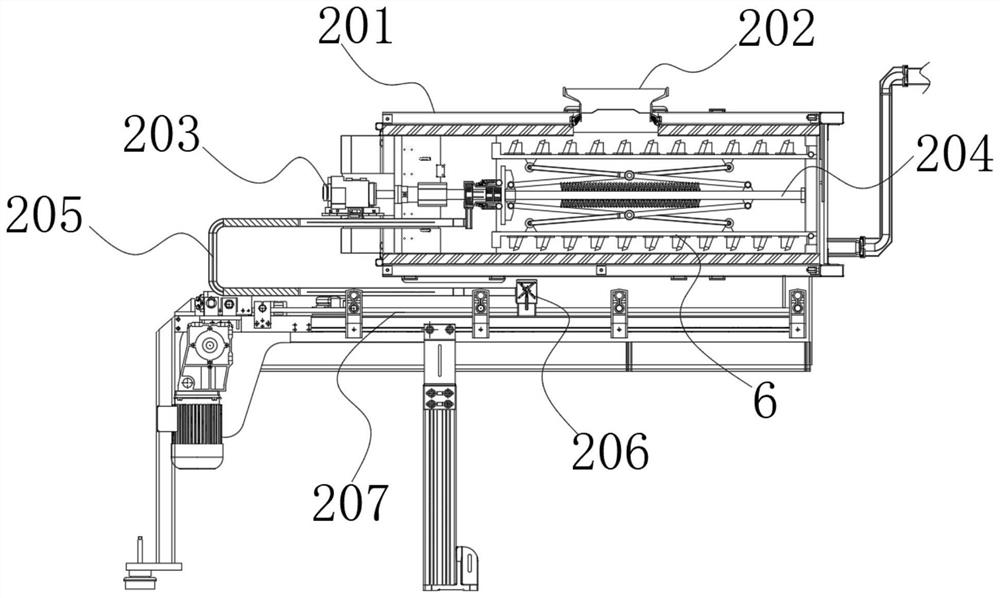

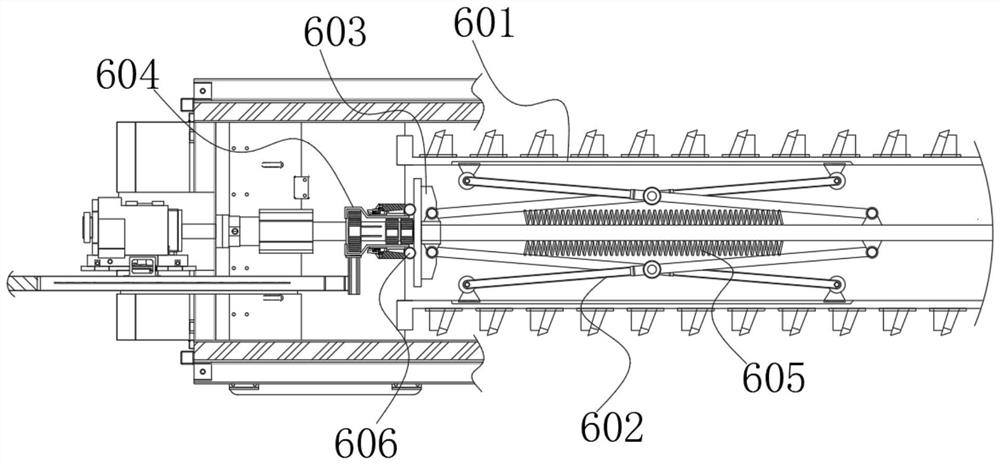

[0028] refer to figure 1 , the present invention provides a technical solution: a titanium oxide modified degradable plastic and production system, which includes a fixed support 1, a main material addition component 2, a mixing barrel 3, a delivery branch pipe 4 and an internal mixing mechanism 5 , wherein, the space orientation circumferential array of the mixing barrel 3 is provided with a plurality of fixed supports 1, each of the fixed supports 1 is supported and fixed on the ground by the lower support, and the upper end surface of the fixed support 1 is installed There are main material adding components 2, and one end of each main material adding component 2 is communicated with a conveying branch pipe 4, and the other end of the conveying branch pipe 4 is communicated with the mixing barrel 3;

[0029] The main material adding component 2 is used to add various raw and auxiliary materials in product formula ratio, and carry out diversified cutting and crushing of mate...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com