Chip testing and braiding machine capable of automatically taking materials, detecting, positioning and braiding

A technology of chip testing and automatic reclaiming, applied in packaging and other directions, can solve problems such as no breakthrough, and achieve the effect of automatic feeding, guaranteeing yield, and overcoming technical difficulties.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0065] In order to better understand the present invention, the technical solution of the present invention will be further described below with reference to the accompanying drawings and examples.

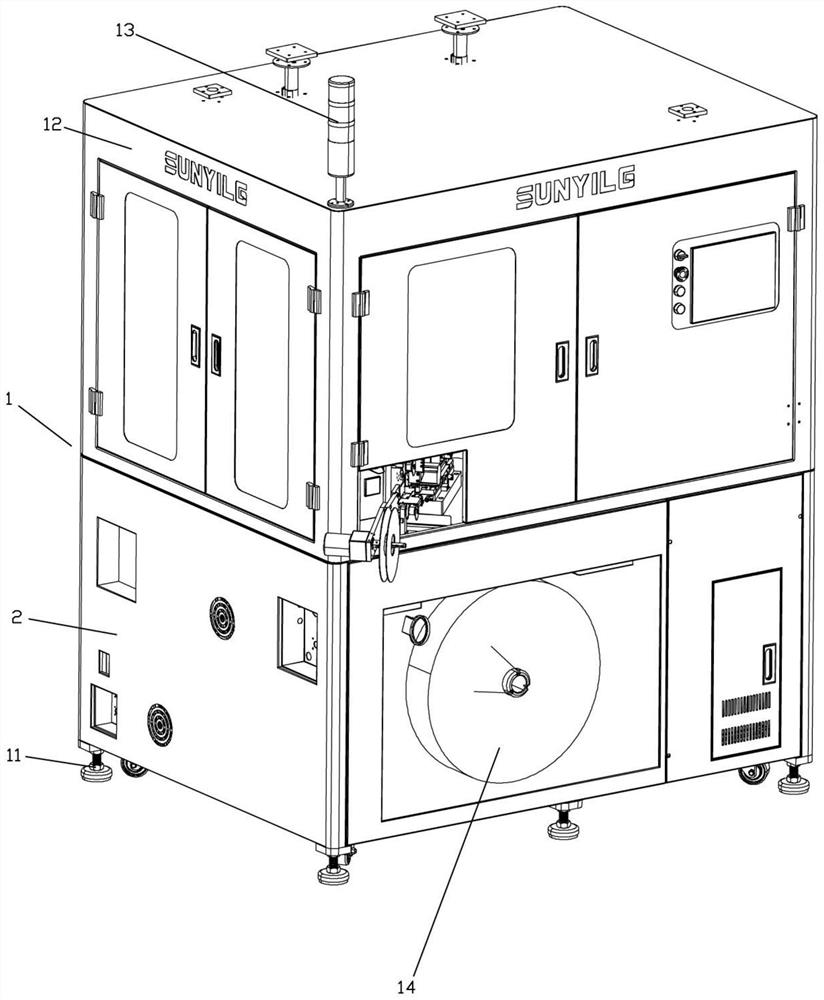

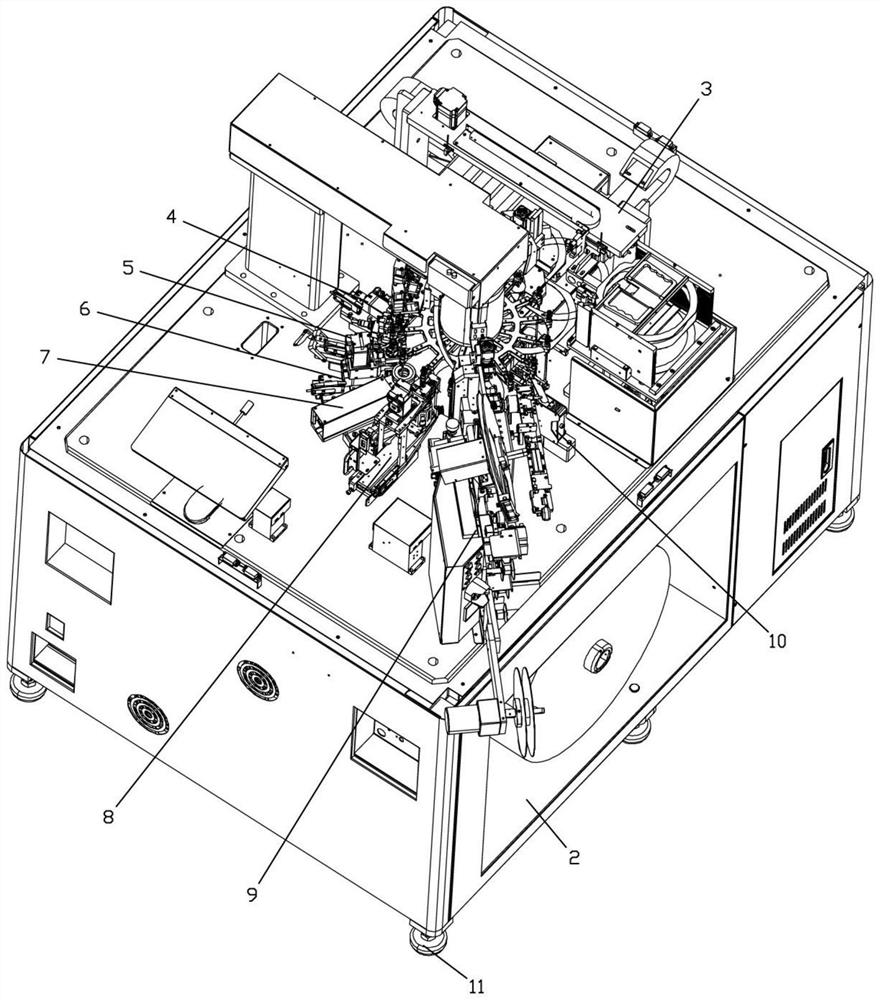

[0066] like Figure 1-2 As shown, a chip test of the present invention can be automatically taking, detects, positioned, and is tested, including host 1, characterized in that the host 1 includes an organizer 2, a seat 2 surface is attached to a sheet. 3, the first positioning mechanism 4, the test mechanism 5, the second positioning mechanism 6, the bottom imaging mechanism 7, the classification mechanism 8, carrier belt mechanism 9, NG mechanism 10 and carrier 14;

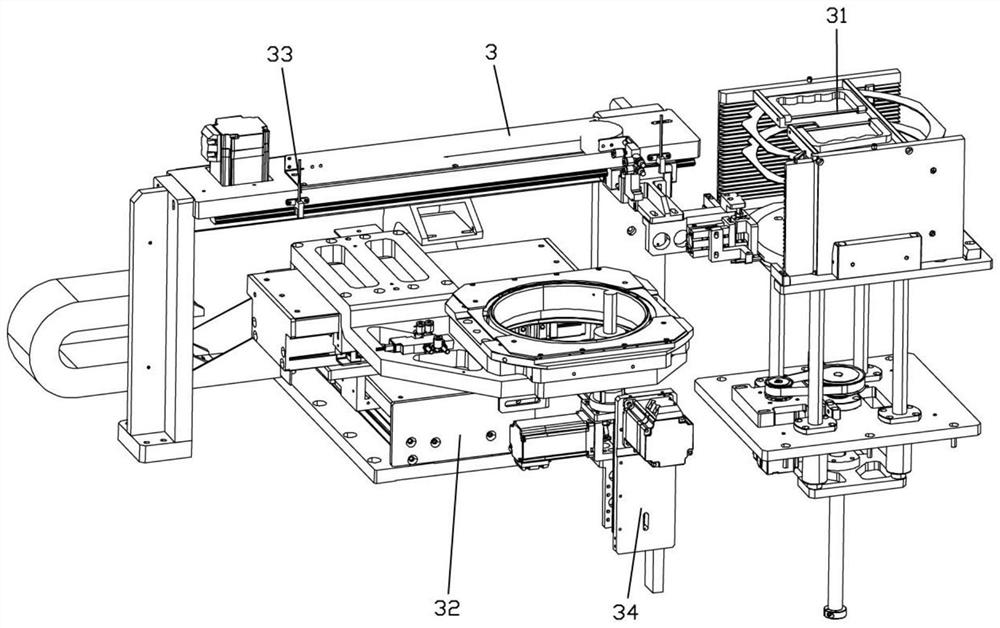

[0067] The upper body 3 includes a cartridge assembly 31, a moving assembly 32, a clamp assembly 33, and a top rising assembly 34;

[0068] The cartridge assembly 31 includes a fixing plate 311, the fixing plate 311 is mounted having a motor 312, and the power output end of the motor 312 is connected to a small pulley 313...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com