Automatically adjusted magnetic tensioner for textile processing

A technology of tensioner and magnetic force, which is applied in the field of magnetic tensioner for textile processing, can solve problems such as low adjustment accuracy, slipping of damping wheel, and affecting textile quality, and achieve the effect of preventing continuous slipping and strong magnetism

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

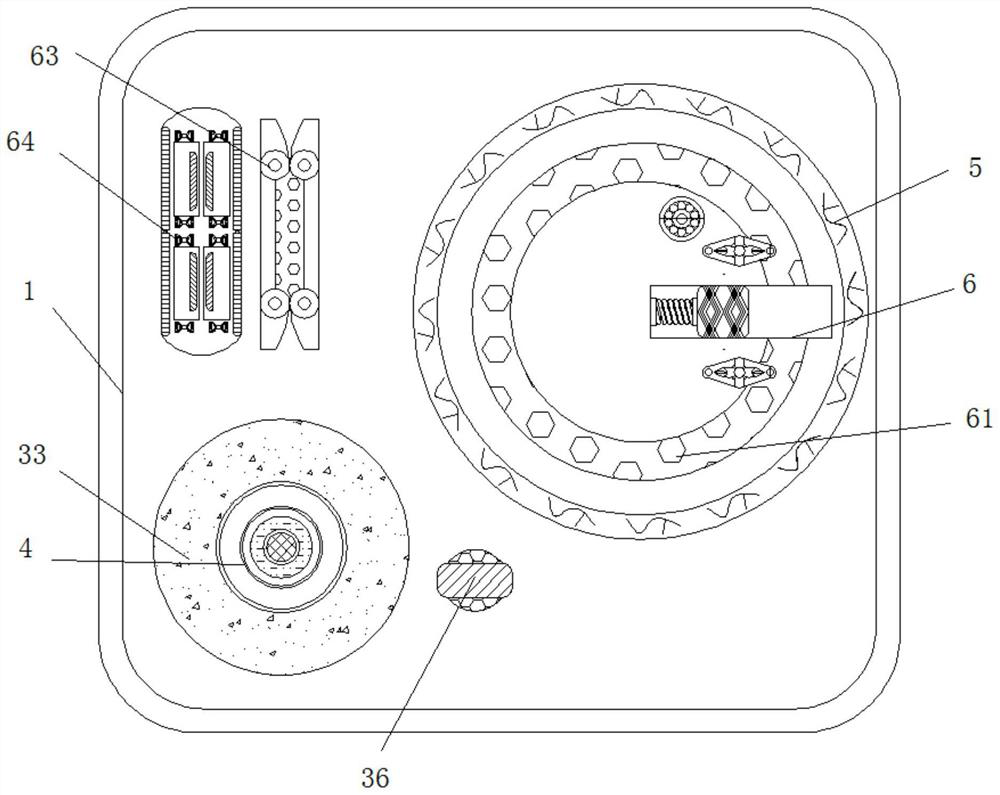

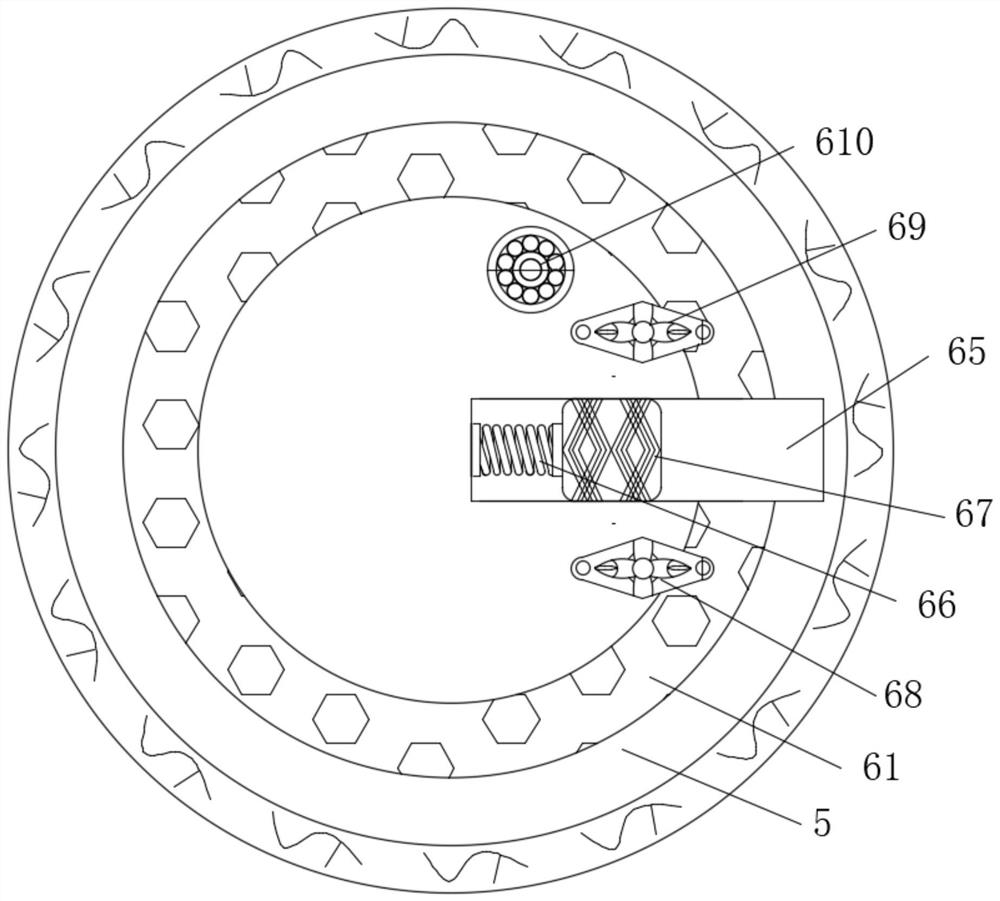

[0026] see Figure 1-2 , a magnetic tensioner for textile processing that can be automatically adjusted, includes a device housing 1, and also includes a mounting shaft 2, an adjustment component 3, a rotating shaft 4, a damping wheel 5, and an induction component 6. The front of the device housing 1 is fixedly connected with Install the shaft 2, the front of the installation shaft 2 is fixedly connected with the adjustment component 3, the front of the equipment housing 1 is fixedly connected with the rotating shaft 4, the front of the rotating shaft 4 is movably connected with the damping wheel 5, and the inside of the damping wheel 5 is fixedly connected with the induction component 6;

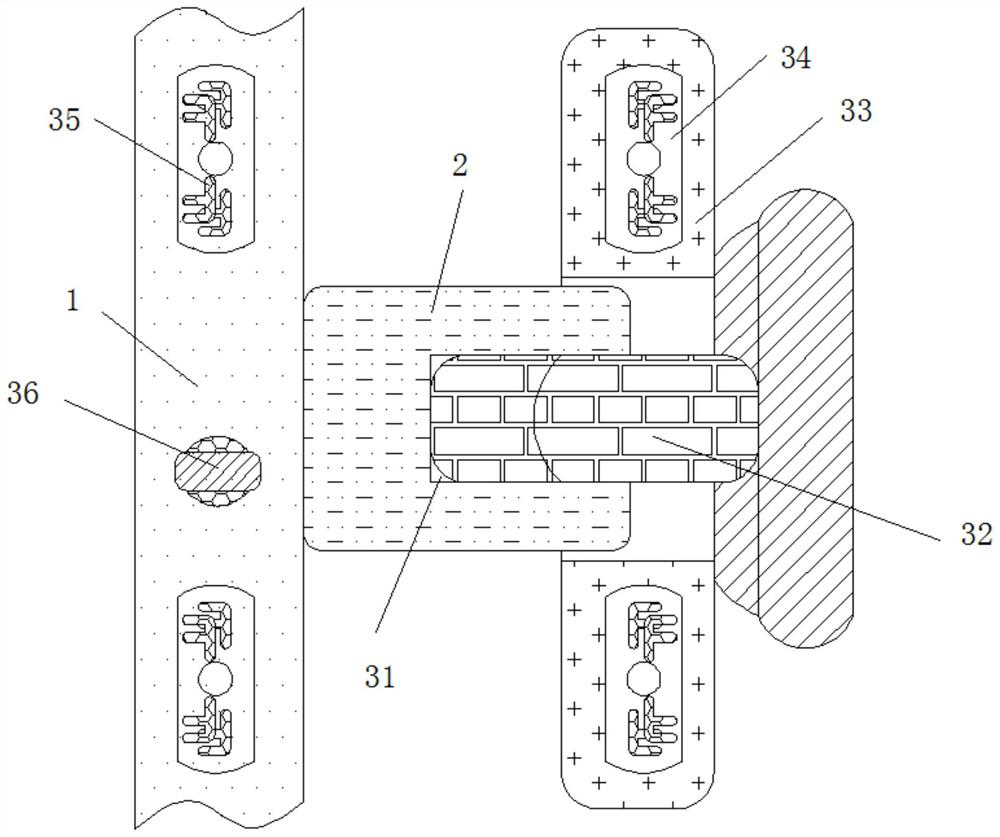

[0027] The adjustment assembly 3 includes a movable groove 31, a magnetostrictive shaft 32, a wool loop 33, a first positive plate 34, and a first negative plate 35. The inside of the installation shaft 2 is provided with a movable groove 31, and the movable groove 31 is fixedly connected wi...

Embodiment 2

[0029] see Figure 1-4 , a magnetic tensioner for textile processing that can be automatically adjusted, includes a device housing 1, and also includes a mounting shaft 2, an adjustment component 3, a rotating shaft 4, a damping wheel 5, and an induction component 6. The front of the device housing 1 is fixedly connected with Install the shaft 2, the front of the installation shaft 2 is fixedly connected with the adjustment component 3, the front of the equipment housing 1 is fixedly connected with the rotating shaft 4, the front of the rotating shaft 4 is movably connected with the damping wheel 5, and the inside of the damping wheel 5 is fixedly connected with the induction component 6;

[0030] The adjustment assembly 3 includes a movable groove 31, a magnetostrictive shaft 32, a wool loop 33, a first positive plate 34, and a first negative plate 35. The inside of the installation shaft 2 is provided with a movable groove 31, and the movable groove 31 is fixedly connected wi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com