Photocatalytic sterilization and disinfection device

A sterilization and disinfection device, photocatalytic technology, applied in the direction of sterilization/microdynamic water/sewage treatment, illumination water/sewage treatment, etc., can solve the problems of unable to use sunlight, single purification function, poor purification effect, etc. Good disinfection effect, wide irradiation range and good purification effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

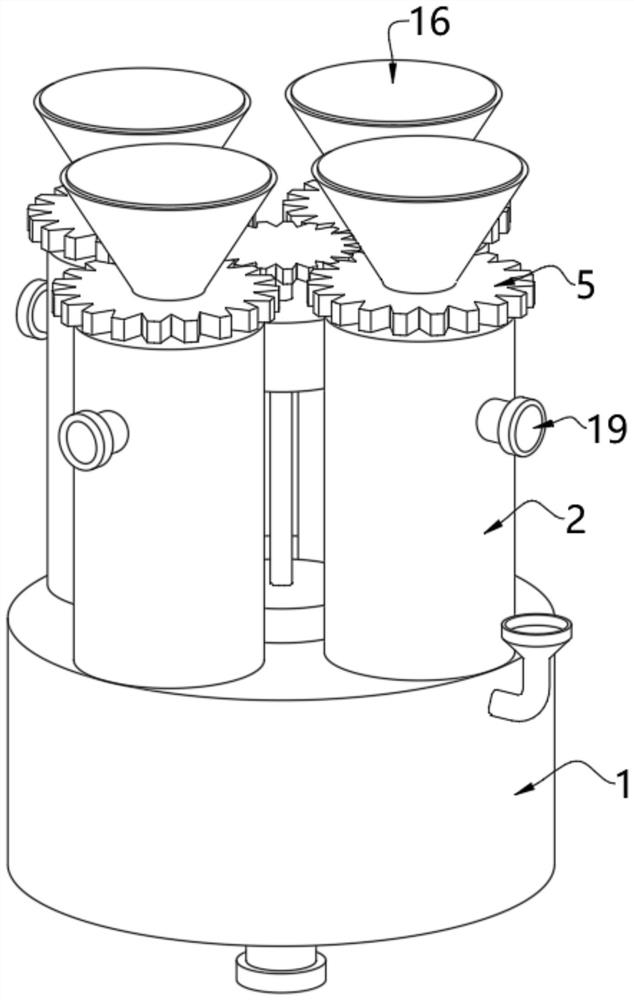

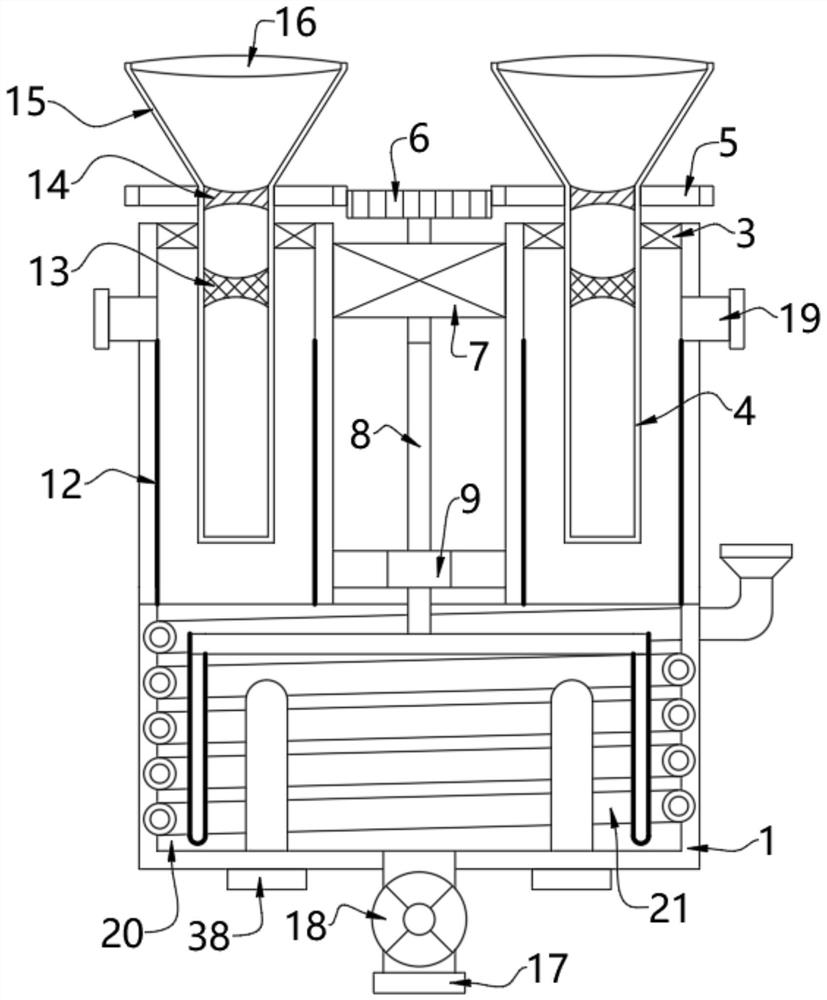

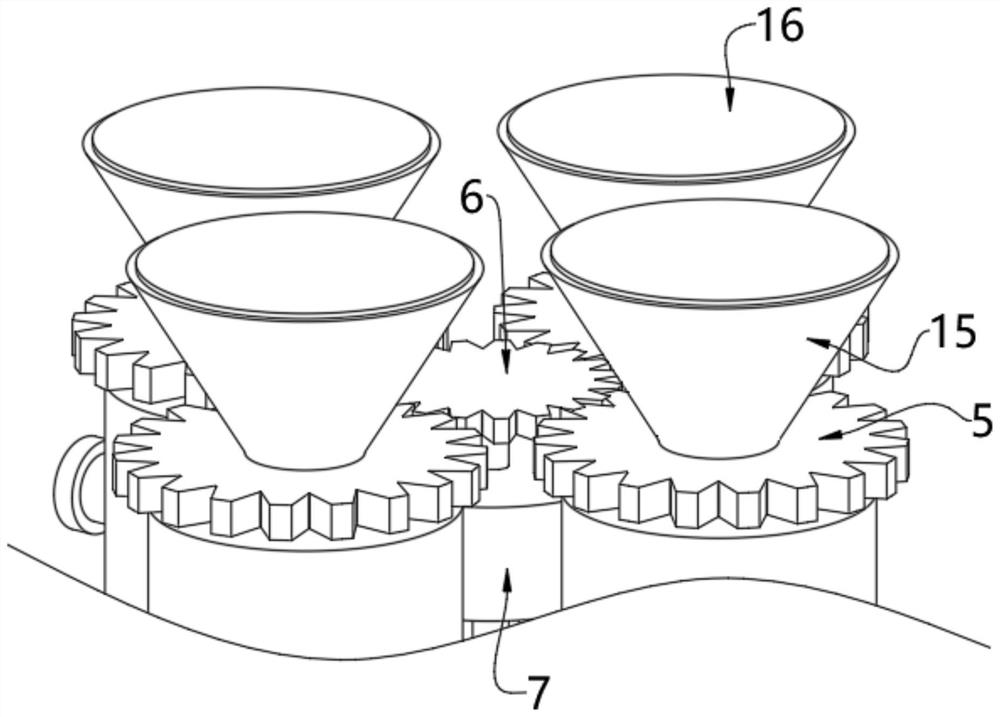

[0048] see Figure 1-5 , photocatalytic sterilization and disinfection device, including

[0049] Bottom cylinder 1, a water inlet pipe 17 is fixedly installed at the center of the bottom of the bottom cylinder 1, a control valve 18 is arranged inside the water inlet pipe 17, an inner cavity 20 is formed inside the bottom cylinder 1, and the edge of the top of the bottom cylinder 1 is evenly fixed Several top cylinders 2 are installed, bearings 3 are fixedly installed on the tops of the inner walls of several top cylinders 2, quartz sleeves 4 are fixedly installed on the inner walls of the bearings 3, double-headed motors 7 are fixedly installed on the outer wall of the top cylinder 2, double-headed The motor 7 can be selected as the 50S90-5-11 model of the Beili brand, and the driving device connected between the double-head motor 7 and the quartz sleeve 4 is used to drive the rotation of the quartz sleeve 4;

[0050] The outer wall of the top tube 2 is fixedly installed wit...

Embodiment 2

[0055] see figure 2 , Figure 4 with Image 6 , on the basis of Embodiment 1, a stirring rod 11 is rotated at the edge of the inner cavity 20, the outer wall of the stirring rod 11 is coated with a titanium dioxide photocatalytic coating 12, and the inner cavity 20 is uniformly provided with an ultraviolet lamp 38, The linkage device connected to the double-head motor 7 and the stirring rod 11 is used to drive the stirring rod 11 to rotate in the inner cavity 20 .

[0056] The linkage device includes a connecting shaft 8 and a connecting rod 10. The output shaft at the bottom of the double-head motor 7 is fixedly equipped with a connecting shaft 8. The connecting shaft 8 is rotatably arranged on the inner wall of the sealing ring 9, and the sealing ring 9 is fixedly installed on the top of the bottom cylinder 1. , the bottom of the connecting shaft 8 is fixedly installed with a connecting rod 10, and the stirring rod 11 is fixedly installed at the end of the stirring rod 11...

Embodiment 3

[0058] see Figure 7 with Figure 8 , on the basis of Embodiment 1 and Embodiment 2, the inner wall of the inner chamber 20 is spirally provided with a coiled tube 21, and the inside of the coiled tube 21 is formed with a lumen 23, and the top end of the coiled tube 21 extends to the outside of the bottom cylinder 1 and is fixed Connected with an addition cylinder 22, the addition cylinder 22 is used to add titanium dioxide powder to the lumen 23;

[0059] The inner wall of the lumen 23 is uniformly provided with a communication groove 24 , and the first discharge device arranged on the inner wall of the communication groove 24 is used to open the communication groove 24 under the action of water pressure.

[0060] The first discharge device comprises a first fixed plate 25, a first column 26, a first valve plate 27 and a first spring 28, the inner wall of the communication groove 24 is fixedly equipped with the first fixed plate 25, and the edge of the first fixed plate 25 o...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com