A nitrogen removal device for denitration wastewater and ammonia nitrogen wastewater

A technology for ammonia nitrogen wastewater and wastewater, applied in water/sewage treatment, multi-stage water/sewage treatment, neutralized water/sewage treatment, etc., can solve problems such as economic loss, low mixing efficiency, and inability to improve the efficiency of ammonia nitrogen removal. Improve consumption speed and cost, avoid forward and backward displacement, and improve nitrogen removal efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

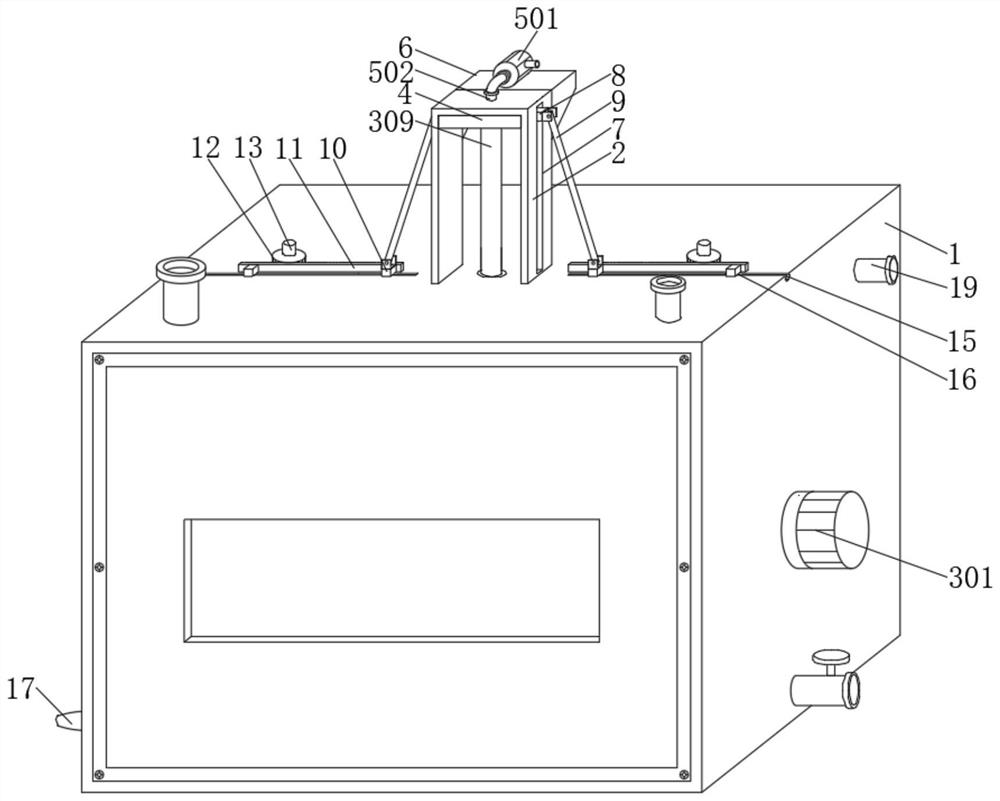

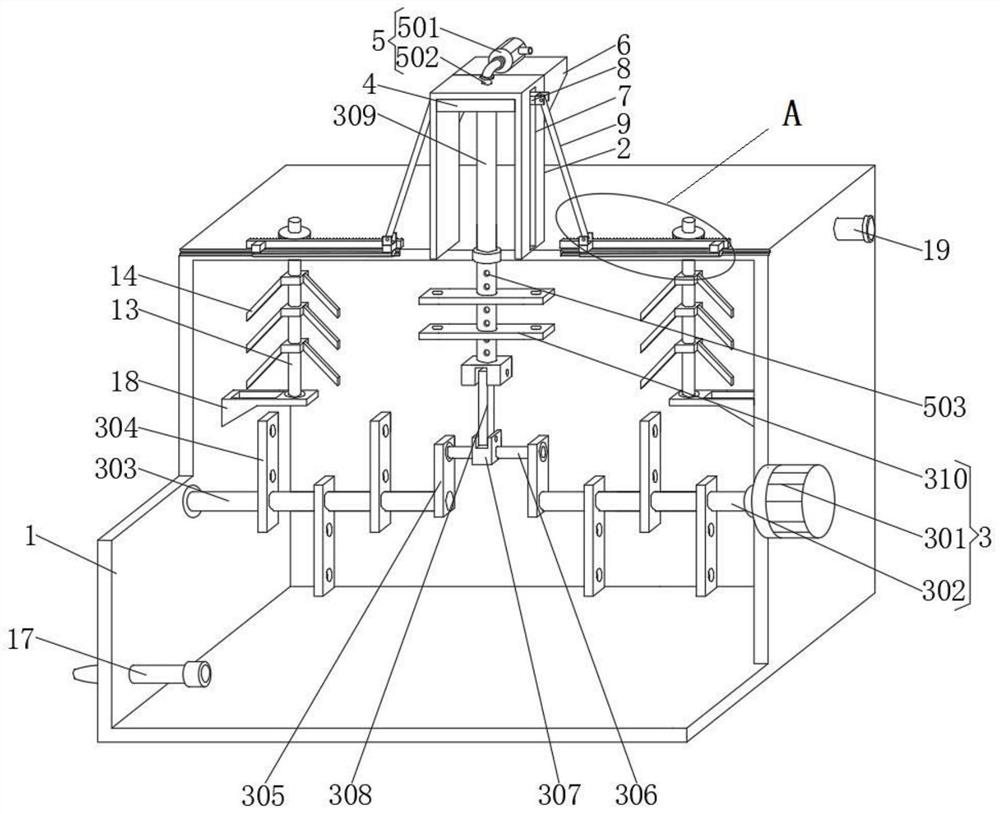

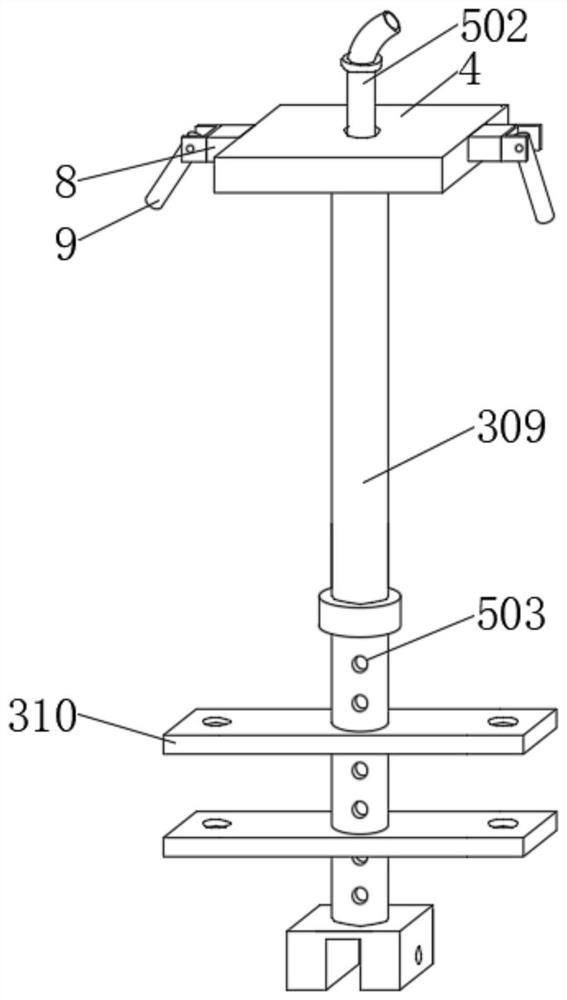

[0036] The following is attached Figure 1-7 The present invention is described in further detail.

[0037] A nitrogen removal device for denitrification wastewater and ammonia nitrogen wastewater, comprising a treatment box 1, the top of the back of the right side of the treatment box 1 is provided with a heating pipe 19, and the heating pipe 19 can use external heating equipment to heat the inside of the treatment box 1, so that the treatment The temperature in the box 1 is always kept at 25°C to 30°C, so as to avoid the effect of the temperature being too high or too low on the nitrogen removal efficiency of the device for wastewater. Mechanism 3, the fixed frame 2 is provided with the jet mechanism 5 used in conjunction with the rapid mixing mechanism 3, the front of the processing box 1 top is connected with the feeding pipe and the medicine feeding pipe successively from left to right, the back side of the fixed frame 2 is provided with The support seat 6 used in conjunct...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com