A kind of antifreeze conductive hydrogel and its preparation method and force response sensing application

A conductive hydrogel and deionized water technology, applied in applications, sensors, diagnostic recording/measurement, etc., can solve the problems of limited types, development and application restrictions, and achieve the effect of simple operation

Active Publication Date: 2022-05-31

HUNAN UNIV OF TECH

View PDF9 Cites 0 Cited by

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

However, due to the limited types of conventional organic antifreeze solvents, the development and application of such gels are greatly restricted

Method used

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

View moreImage

Smart Image Click on the blue labels to locate them in the text.

Smart ImageViewing Examples

Examples

Experimental program

Comparison scheme

Effect test

Embodiment 1

Embodiment 2

Embodiment 3

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

| width | aaaaa | aaaaa |

Login to View More

Abstract

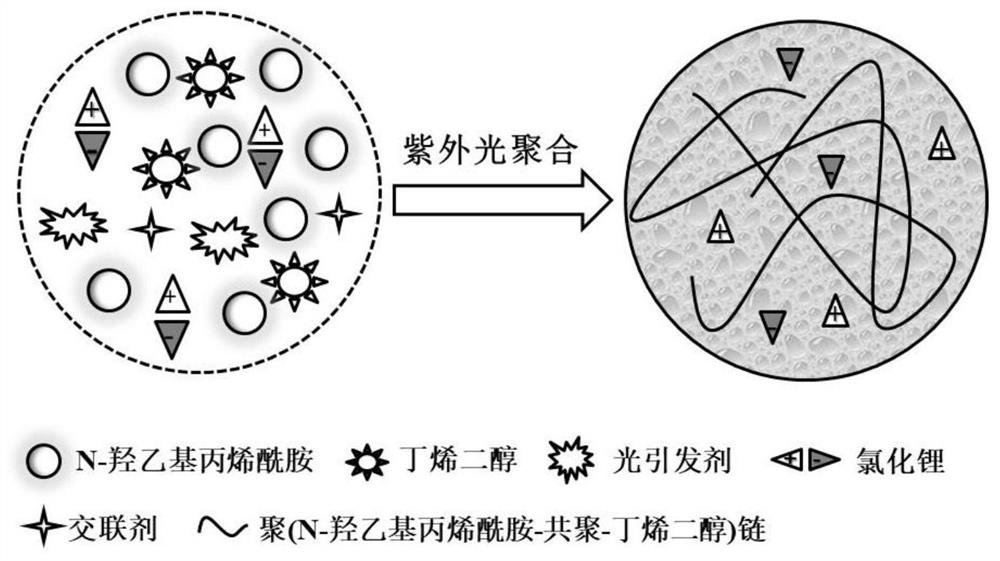

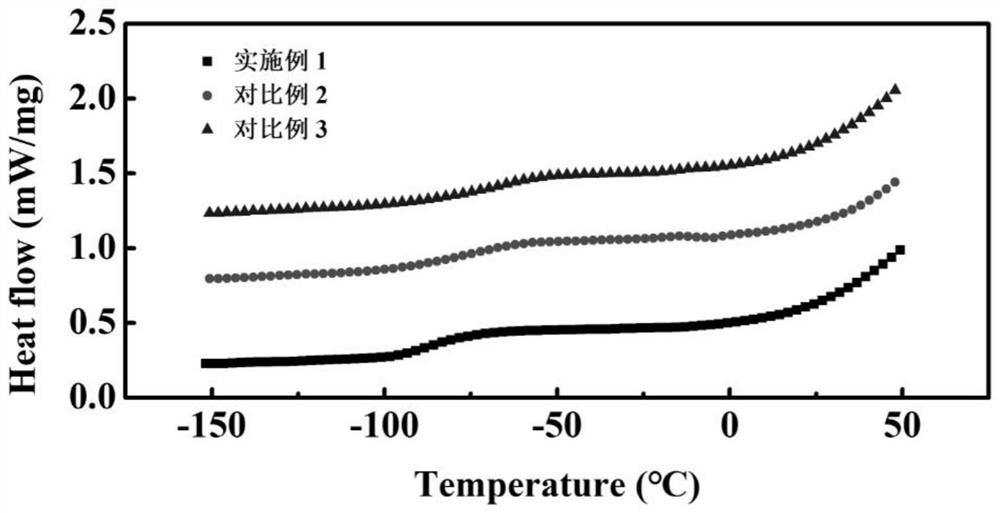

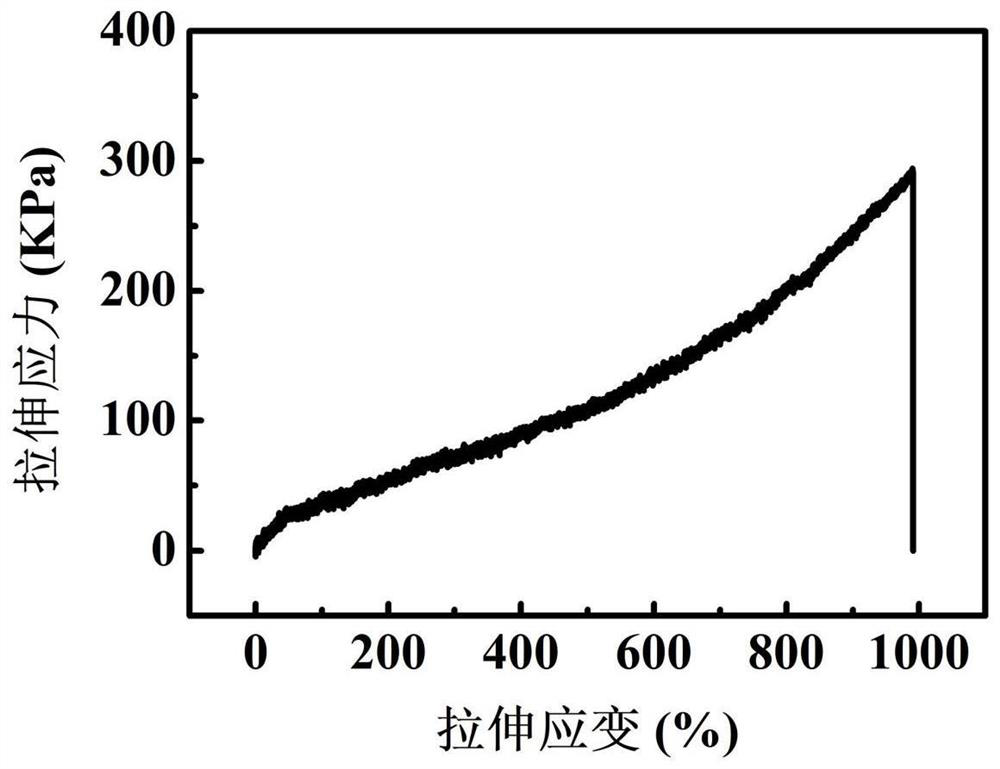

The invention belongs to the field of polymer material chemistry, and discloses an antifreeze conductive hydrogel and its preparation method and force response sensing application. The antifreeze conductive hydrogel includes the following components in mass percentage: butylene glycol 10 %‑30%, N‑hydroxyethylacrylamide 50%‑70%, photoinitiator 1%‑3%, crosslinker 0.1%‑0.3%, lithium chloride 1%‑7%, deionized water 9.7% ‑37.9%. The preparation method comprises the following steps: 1) adding lithium chloride, N-hydroxyethylacrylamide, butylene glycol, a cross-linking agent and a photoinitiator into deionized water, stirring evenly, and reacting to form a prepolymer solution; 2) adding The prepolymer solution is injected into the mold, and then transferred to a UV lamp for polymerization to form a gel. The invention overcomes the limitation that most traditional antifreeze gels are based on organic gels, and realizes the effect that the water-based gel has excellent antifreeze properties.

Description

A kind of antifreeze conductive hydrogel and its preparation method and force-responsive sensing application technical field The present invention relates to the field of polymer material chemistry, more specifically to a kind of antifreeze conductive hydrogel and preparation thereof. Preparation method and application of force-responsive sensing. Background technique Conductive gel is a three-dimensional polymer hydrogel with electrical conductivity, however, most of the hydrogel itself It is not conductive, and conductive fillers need to be filled in the hydrogel medium to achieve its conductive properties, and the gel contains a large amount of water, which crystallizes at low temperatures resulting in most conductive gels at sub-zero conditions due to the lack of antifreeze properties. Under these conditions, these conductive gels will lose their electrical conductivity or stretchability, which greatly limits their applications in smart sensing, smart driving a...

Claims

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More Application Information

Patent Timeline

Login to View More

Login to View More Patent Type & Authority Patents(China)

IPC IPC(8): C08J3/075C08F220/58C08F216/04C08F222/38C08F212/36C08F222/14C08F2/48C08F2/44C08K3/16A61B5/11C08L33/24

CPCC08J3/075C08F220/58C08F2/48C08F2/44C08K3/16A61B5/11A61B5/1126C08J2333/24C08F216/04C08F222/385C08F212/36C08F222/102

Inventor 龚亮汤力崔婷汤建新

Owner HUNAN UNIV OF TECH

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com