Thermal expansion microsphere and preparation method thereof

A technology of heat-expandable microspheres and microspheres, which is applied in the field of foaming materials, can solve the problems of high expansion rate high-temperature foam stabilization performance, no effective solution, and the difficulty of heat-resistant high-temperature thermal expansion microspheres, etc., to improve the use of Comfortable, good foaming effect, guaranteed homogeneity effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Synthetic example 2

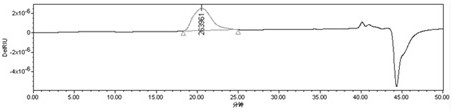

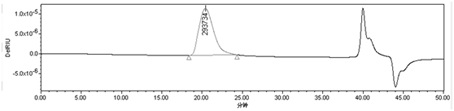

[0052] Add 89.5g of water and 1.5g of gelatin to the reaction bottle, stir evenly and heat it up to 80°C, then add a mixed solution containing 9g of methyl methacrylate and 0.03g of benzoyl peroxide dropwise to the gelatin The polymerization reaction is carried out in the aqueous solution, and the drip rate is controlled by a peristaltic pump, and the dripping is uniformly added in about 3 hours.

[0053] During the dropping process, the polymerized PMMA precipitates out of the system, and is suspended in the system due to the stirring and dispersing agent. After all the reactions are completed, the required ultra-high molecular weight PMMA-2 is obtained by filtration. The molecular weight Mw is 304193, and its GPC spectrum See attached figure 2 .

Synthetic example 3

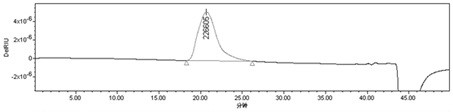

[0055] Add 90g of water and 1g of gelatin to the reaction bottle, stir evenly and heat it up to 75°C, then add the mixed solution containing 9g of methyl methacrylate and 0.02g of benzoyl peroxide dropwise to the gelatin aqueous solution Carry out the polymerization reaction in the middle, use the peristaltic pump to control the dropping rate, and drop evenly for about 3 hours.

[0056] During the dropping process, the polymerized PMMA precipitated from the system, and was suspended in the system due to the stirring and dispersing agent. After all the reactions were completed, the required ultra-high molecular weight PMMA-3 was obtained by filtration. The molecular weight Mw was 346492, and its GPC spectrum See attached image 3 .

Embodiment 1

[0058] 5g of PMMA-1 was dissolved in 10g of dichloromethane, 95g of acetic acid was added as a core material, 1g of polyvinyl alcohol was added as a dispersant, and 0.5g of sodium dodecylbenzenesulfonate was added as an emulsifier;

[0059] After stirring evenly, add 400g of water, control the solution temperature to maintain between 10-20°C and keep stirring for 2 hours to make the solution emulsify evenly;

[0060] After the emulsification was uniform, the emulsion was placed on a tray and dried at 35°C until the dichloromethane was completely removed to obtain an aqueous solution 1 of PMMA-coated organic acid microspheres. attached Figure 4 It is the microscopic observation figure of the microsphere aqueous solution 1 of PMMA coating organic acid.

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com