Polylactic acid carrier color master batch and preparation method thereof

A technology of polylactic acid and color masterbatch, which is applied in the direction of adding pigments in single-component polyester rayon filament and spinning solution, can solve the problems of large amount of addition and the influence of mechanical properties of finished fibers, so as to achieve no three-waste pollution. , the processing technology is easy to control, the effect of low filter value

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

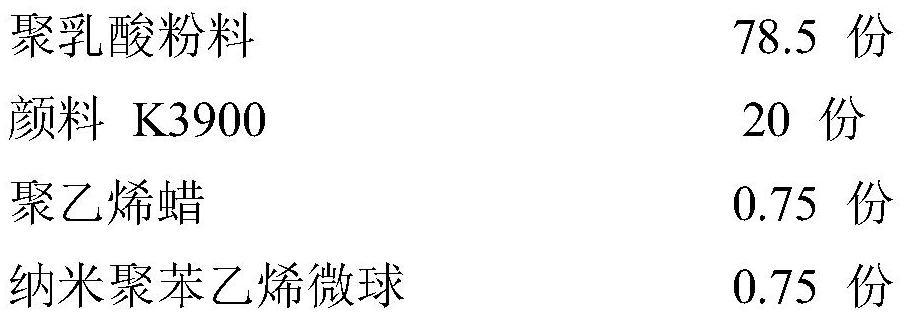

[0025] Polylactic acid carrier masterbatch, components:

[0026]

[0027]

[0028] Preparation method: first put the polylactic acid slices into the grinding disc mill for grinding, and the powder is sent to the vibrating screen by the discharge fan, and the polylactic acid powder with a particle size greater than 60 meshes is sieved, and then the polylactic acid powder, pigment and dispersant (a mixture of polyethylene wax and nano-polystyrene microspheres) were added to the high-speed mixer according to the above ratio and stirred for a certain period of time (preferably 2min) to make the materials evenly mixed, and the mixture was quantitatively fed into the twin-screw by weight loss. Extruder, the material is melted, sheared and mixed, devolatilized, re-sheared, etc., and extruded through the die head of the extruder. The extrusion temperature is preferably 225°C. After drying, enter the granulator to cut into particles of the required size, and finally sieve in the ...

Embodiment 2

[0030] Polylactic acid carrier masterbatch, components:

[0031]

[0032] The preparation process is the same as in Example 1, but the extrusion temperature of the extruder is preferably 220°C. The pressure filtration performance and viscosity drop test of the finished color masterbatch showed that the pressure filtration value was 0.029MPa / g, and the viscosity dropped to 0.216dl / g, which met the long-term stable operation requirements of the polylactic acid colored yarn spinning process.

Embodiment 3

[0034] Polylactic acid carrier masterbatch, components:

[0035]

[0036] The preparation process is the same as in Example 1, but the extrusion temperature of the extruder is preferably 212°C. The pressure filtration performance and viscosity drop test of the finished color masterbatch showed that the pressure filtration value was 0.056MPa / g, and the viscosity dropped to 0.342dl / g, which met the long-term stable operation requirements of the polylactic acid colored yarn spinning process.

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size (mesh) | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| elongation | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com