Modified carbon black applied to coloring spinning resin and preparation method thereof

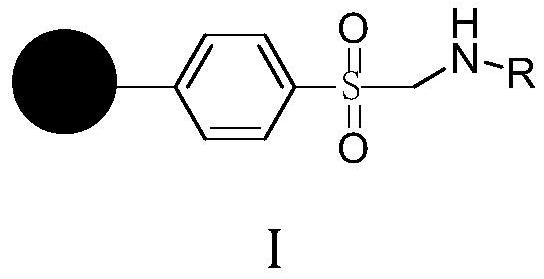

A technology of modified carbon black and modified carbon, which is applied in the preparation/purification of carbon, adding pigments in spinning solution, etc., which can solve the problem of low reaction grafting rate, difficult product quality to achieve the desired result, and inability to directly Apply resin fiber coloring and other problems to achieve the effect of easy dispersion

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

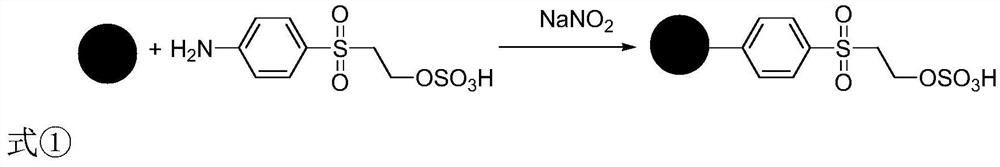

[0044] (1) carbon black grafting reaction

[0045] The reaction formula is:

[0046]

[0047]In a 1000 mL four-necked flask, 200 g of carbon black, 70 g of p-(β-ethylsulfone sulfate) aniline and 600 g of deionized water were added. Raise the temperature to 40° C., keep the temperature and react for 30 minutes, then gradually add 80 g of 25% sodium nitrite solution in portions, and react at this temperature for 3 hours. The particle size monitoring is detected by a nanometer particle size zeta potential analyzer, and the test particle size is D90=120nm. The test pH was 4-5, and there was no residue after filtering through a 0.25 μm membrane, and the grafting was considered successful. Proceed to the next experiment.

[0048] (2) Second group grafting

[0049]

[0050] Put the sand-milled material (particle size D90=105nm) into a 2000ml four-neck bottle, add 176g of 15% sodium carbonate solution under stirring, the feeding speed is 4ml / min, heat to 40°C after adding, k...

Embodiment 2

[0052] (1) carbon black grafting reaction

[0053] The reaction formula is:

[0054]

[0055] In a 1000 mL four-necked flask, 200 g of carbon black, 70 g of p-(β-ethylsulfone sulfate) aniline and 600 g of deionized water were added. Raise the temperature to 40° C., keep the temperature and react for 30 minutes, then gradually add 80 g of 25% sodium nitrite solution in portions, and react at this temperature for 3 hours. The particle size monitoring is detected by a nanometer particle size zeta potential analyzer, and the test particle size is at D90=125nm. The test pH was 4-5, and there was no residue after filtering through a 0.25 μm membrane, and the grafting was considered successful. This material can be used as the first reactant for PP stock solution coloring. If materials for fine denier filaments are required, sand milling is required, and the above materials are directly added to the hopper of a horizontal sand mill, using 0.6-0.8mm zirconium beads, sanding for ...

Embodiment 3

[0060] (1) carbon black grafting reaction

[0061] The reaction formula is:

[0062]

[0063] In a 1000 mL four-necked flask, 200 g of carbon black, 30 g of p-(β-ethylsulfone sulfate) aniline and 600 g of deionized water were added. Stir at room temperature (measured at 15° C.), keep warm for 30 minutes, then gradually add 73.5 g of 15% sodium nitrite solution in portions, and react at this temperature for 5 hours. The particle size monitoring is detected by a nanometer particle size zeta potential analyzer, and the test particle size is at D90=125nm. The pH of the test was 4.5, and there was no residue after filtering through a 0.25 μm membrane, and the grafting was considered successful. Put the above materials directly into the feeding hopper of a horizontal sand mill, use 0.6-0.8 mm zirconium beads, and sand them in a single cycle for 1 hour. The particle size D90=110nm is detected by a nano-particle size zeta potential analyzer, and the next experiment is carried out...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com