A production method, production system and functional polyester fiber of functional polyester

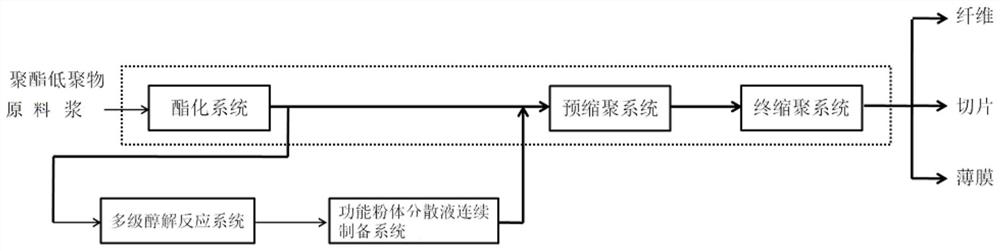

A production system and production method technology, applied in the direction of adding pigments in single-component polyester rayon filament, spinning solution, etc., can solve the problem of poor spinning performance of functional polyester melt, difficult to spin fine denier or ultra-fine denier. The problems of fine denier and functional powder are difficult to achieve the effect of enhancing interaction force, uniform structure and reducing agglomeration

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

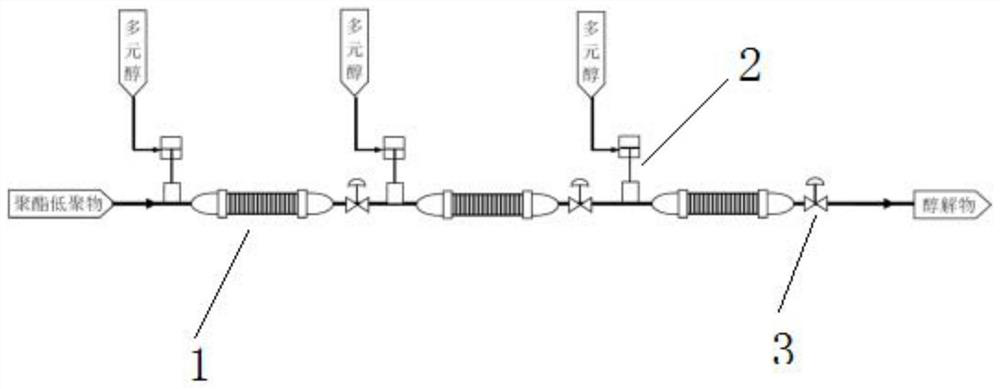

Method used

Image

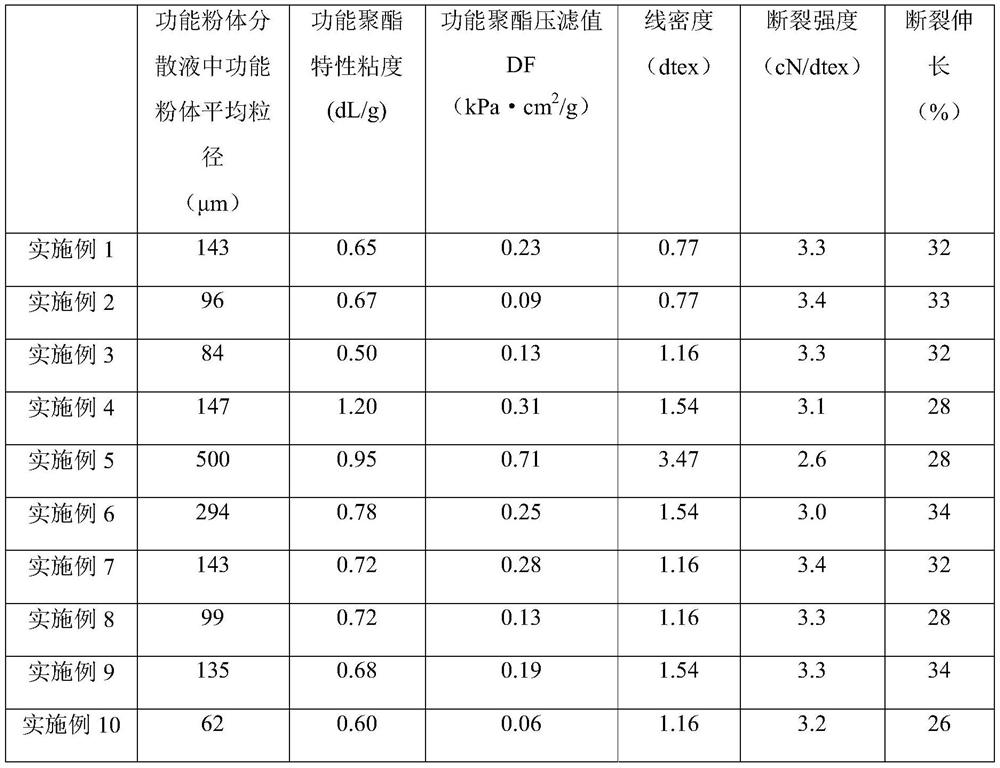

Examples

Embodiment 1

[0049] The raw material slurry of terephthalic acid and ethylene glycol prepared into a polyester oligomer with an alkyd molar ratio of 1.12 is continuously and uniformly transported to the vertical first esterification reaction tank and the vertical first esterification reaction tank at a flow rate of 4601kg / h. The esterification reaction is carried out in an esterification reaction system composed of diesterification reactors, the reaction temperature of the first esterification reactor is 265°C, and the reaction temperature of the second esterification reactor is 268°C. The catalyst ethylene glycol antimony solution with a concentration of 3 wt% was continuously and uniformly injected into the second esterification reaction tank at a flow rate of 54.8 kg / h. When the hydroxyl value of the polyester oligomer reaches 84mgKOH / g, the oligomer delivery metering device consisting of a pump and a flow meter is continuously and stably withdrawn from the second esterification reactor ...

Embodiment 2

[0056] The raw material slurry of terephthalic acid and ethylene glycol prepared into a polyester oligomer with an alkyd molar ratio of 1.12 is continuously and uniformly transported to the vertical first esterification reaction tank and the vertical first esterification reaction tank at a flow rate of 4601kg / h. The esterification reaction is carried out in an esterification reaction system composed of diesterification reactors, the reaction temperature of the first esterification reactor is 265°C, and the reaction temperature of the second esterification reactor is 268°C. The catalyst ethylene glycol antimony solution with a concentration of 3 wt% was continuously and uniformly injected into the second esterification reaction tank at a flow rate of 54.8 kg / h. When the hydroxyl value of the polyester oligomer reaches 84mgKOH / g, the oligomer delivery metering device consisting of a pump and a flow meter is continuously and stably withdrawn from the second esterification reactor ...

Embodiment 3

[0063] The terephthalic acid and ethylene glycol are formulated into a slurry with an alkyd molar ratio of 1.05, and the slurry is continuously and uniformly transported at a flow rate of 4516kg / h to the vertical first esterification reactor and the vertical second esterification reactor. The esterification reaction is carried out in the esterification reaction system, the reaction temperature of the first esterification reaction tank is 265°C, and the reaction temperature of the second esterification reaction tank is 270°C. The catalyst ethylene glycol antimony solution with a concentration of 3 wt% was continuously and uniformly injected into the second esterification reaction tank at a flow rate of 54.8 kg / h. When the hydroxyl value of the polyester oligomer reaches 40mgKOH / g, the oligomer delivery and metering device consisting of a pump and a flow meter is continuously and stably withdrawn from the second esterification reactor at a flow rate of 3834kg / h.

[0064] The pol...

PUM

| Property | Measurement | Unit |

|---|---|---|

| hydroxyl value | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com