Heat-vulcanized silicone rubber base coat binder and preparation method thereof

A heat-vulcanized silicone rubber and adhesive technology, which is applied in the direction of adhesives, non-polymer organic compound adhesives, non-polymer adhesive additives, etc., can solve the problem of affecting construction personnel and the environment, strong smell of benzene solvents, Hazards and other issues, to achieve stability and retrograde improvement, reduce bonding failure, and simplify the effect of the solvent system

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0024] This embodiment relates to a thermally vulcanized silicone rubber primer adhesive with high viscosity, good stability, low toxicity and high efficiency.

[0025] Configure the production process:

[0026] First, take 14.6g of tetrabutyl titanate and 5.5g of ethyl acetoacetate in a round-bottomed flask, mechanically stir at 80°C for 0.5h, place it at room temperature, add 80.0g of vinyltriethoxysilane, and mix well. That is, the thermally vulcanized silicone rubber primer is prepared.

Embodiment 2~5 and comparative example 1~2

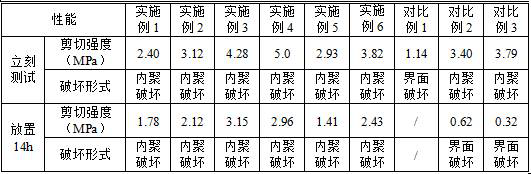

[0028] Refer to the production process described in Example 1, carry out Examples 2-5 and Comparative Examples 1-2, the specific parameters are shown in Table 1 below, and prepare the primer.

[0029] Table 1

[0030]

PUM

| Property | Measurement | Unit |

|---|---|---|

| shear strength | aaaaa | aaaaa |

| shear strength | aaaaa | aaaaa |

| shear strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com