Steam generator with balanced pressure

A technology of steam generator and pressure sensor, which is applied in steam generation, steam generation method, steam boiler, etc., can solve the problems of uneven heat exchange on the left and right sides, fatigue damage of heat exchange elements, unbalanced pressure, etc. Scaling and heating effect, improve heating efficiency, the effect of accurate results

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

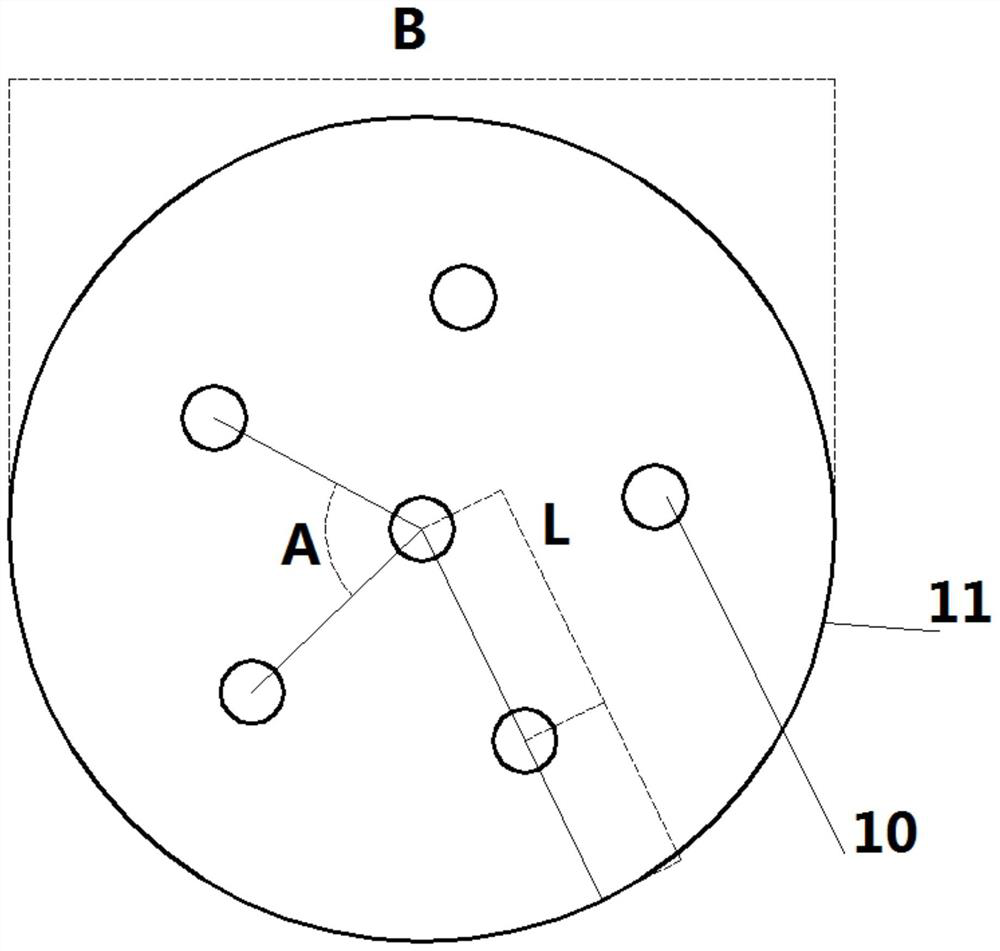

[0037] A steam generator such as Figure 5 As shown, the steam generator includes an electric heating device 10 and a steam drum 11 , the electric heating device 10 is arranged in the steam drum 11 , and the steam drum 11 includes a water inlet pipe 5 and a steam outlet 6 . Steam outlet 6 is arranged on steam drum top.

[0038] Preferably, the steam drum is a cylindrical structure.

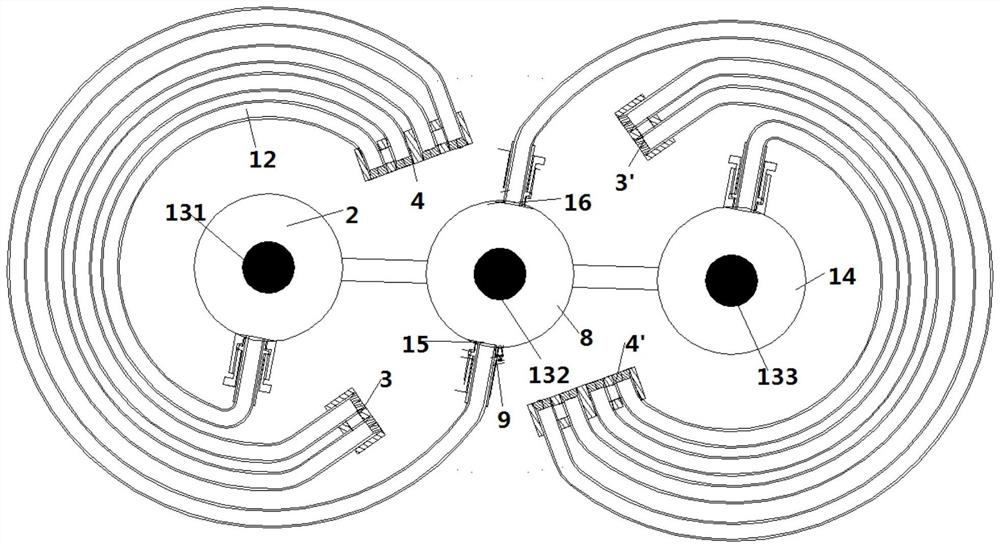

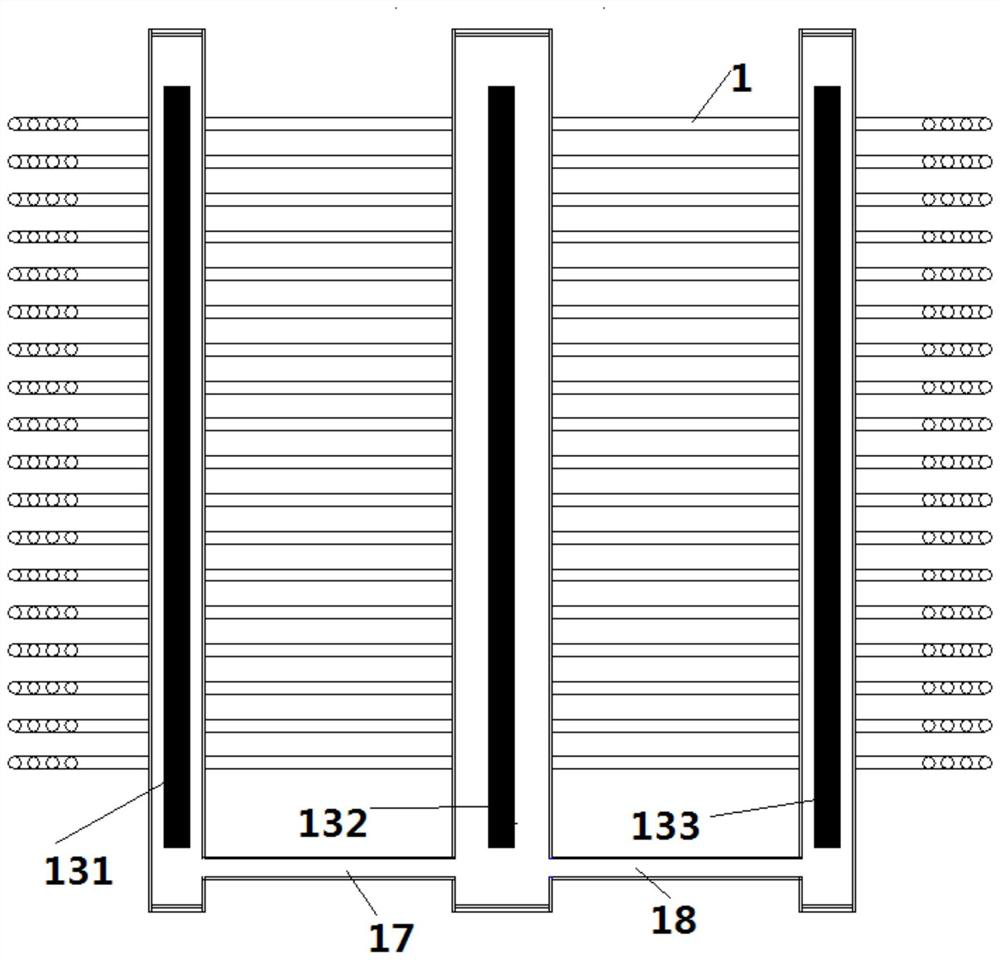

[0039] figure 1 A top view of the electric heating device 10 is shown, as figure 1 As shown, the electric heating device 10 includes a left tube box 2, a middle tube box 8, a right tube box 14 and a coil 1, and the coil 1 includes a left coil 101 and a right coil 102, and the left coil 101 and the left tube Box 2 communicates with middle tube box 8, right coil 102 communicates with right tube box 14 and middle tube box 8, fluid is sealed in left tube box 2, middle tube box 8, right tube box 14 and coil tube 1 circulation, the electric heater 10 is provided with electric heaters 131, 132, 133, ...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap