Power system machine room temperature control coordination control method based on optimal working point

A power system, coordinated control technology, applied in mechanical equipment, high-efficiency regulation technology, climate sustainability, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

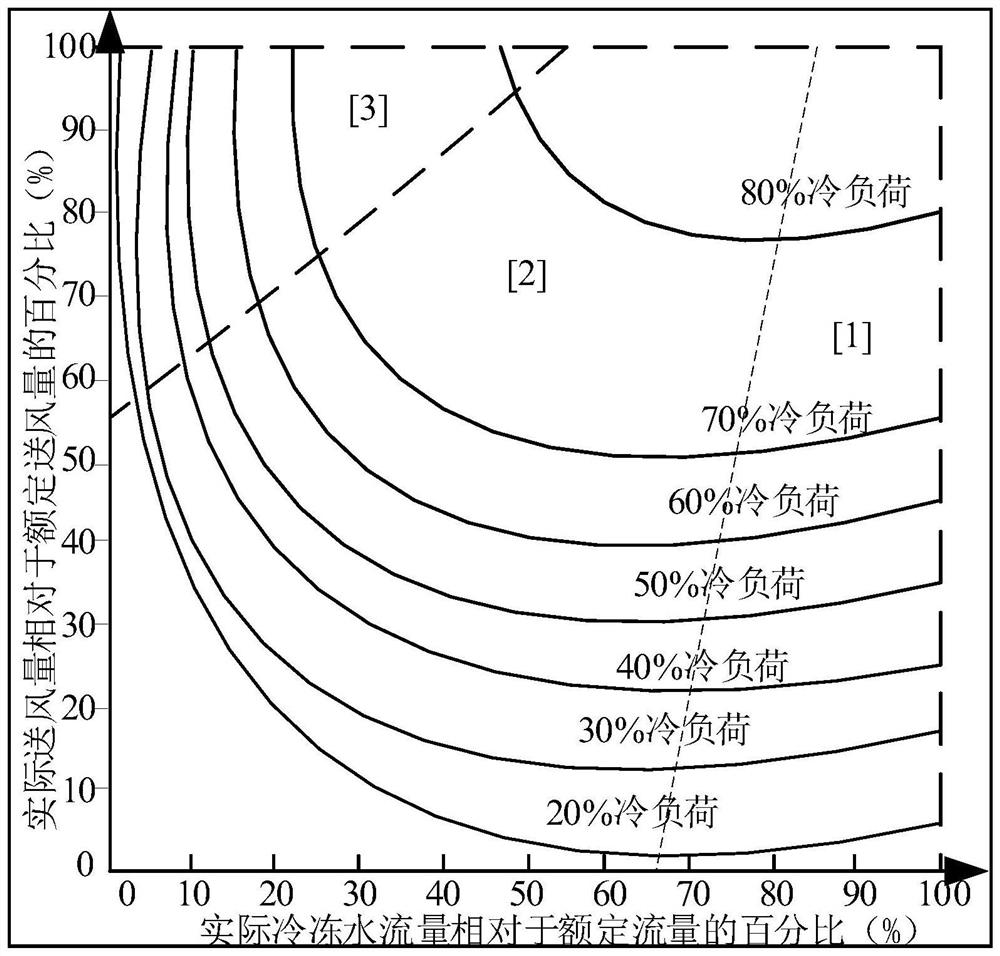

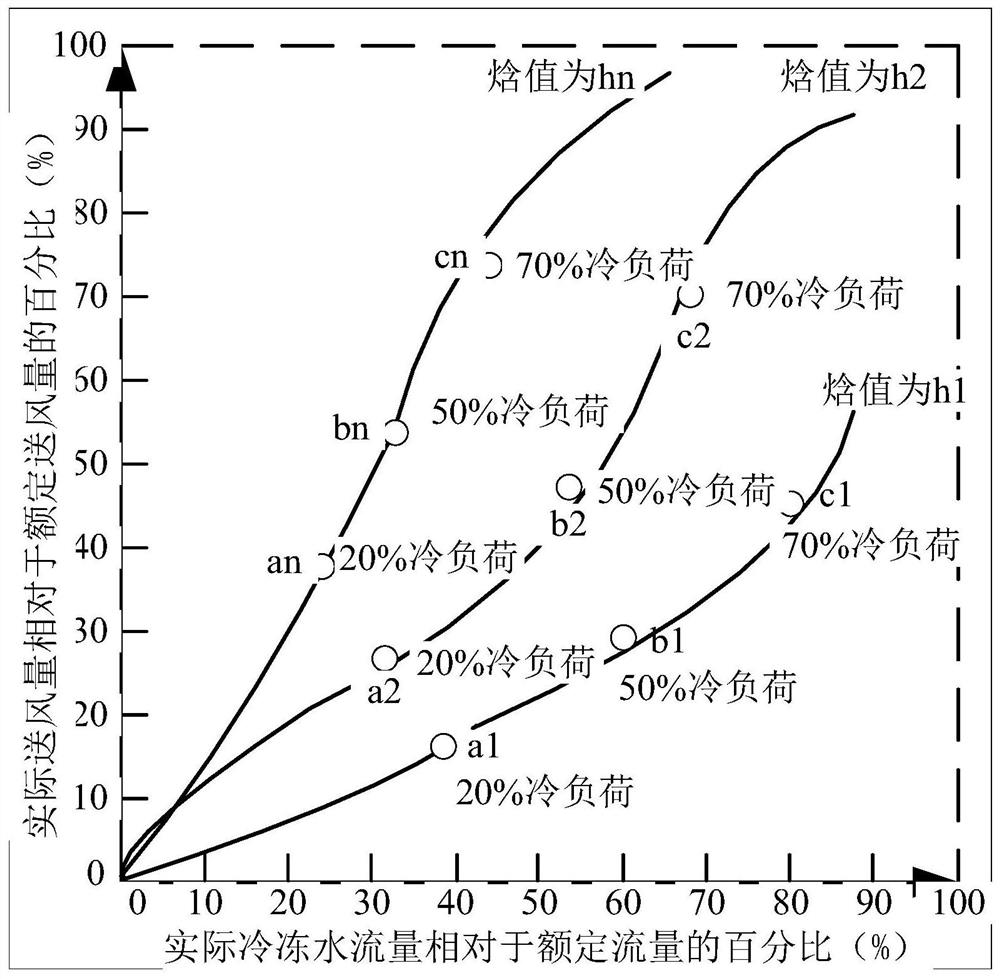

[0036] Because the energy consumption curves of fans and pumps are different, when the cooling load demand is given, there is an optimal operating point to minimize the sum of energy consumption of fans and chilled water pumps. Based on this understanding, the following energy-saving control ideas can be drawn:

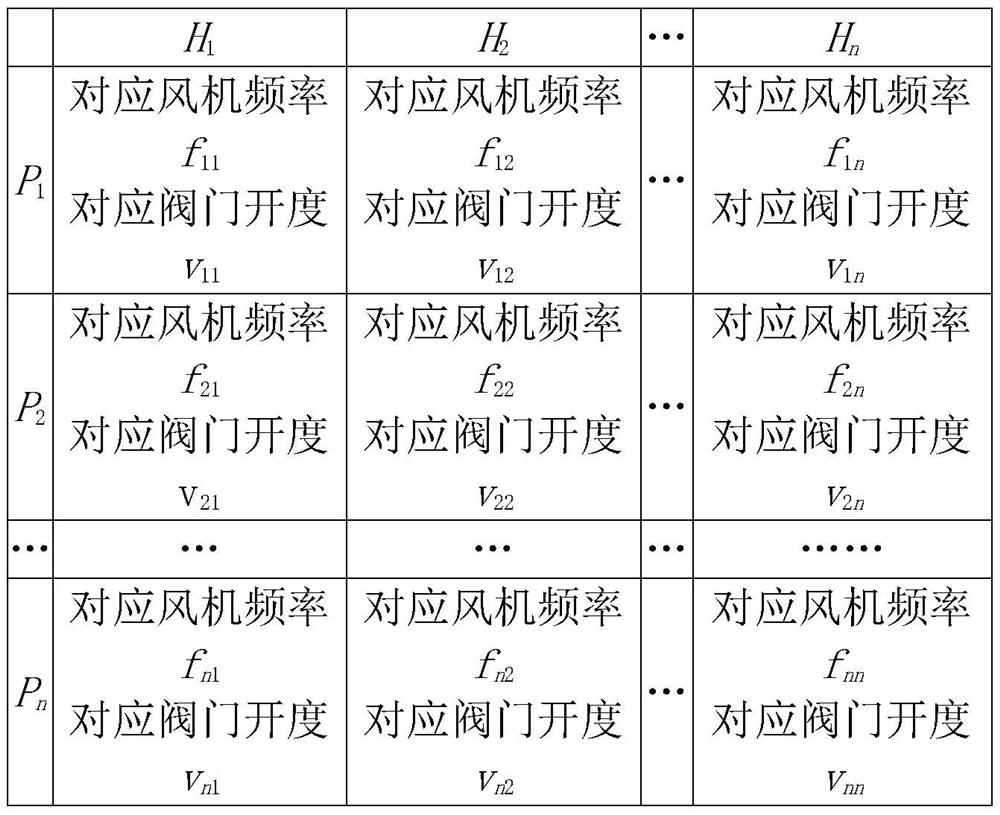

[0037] 1) Store parameters such as fan frequency, chilled water valve opening, and load at the optimal operating point corresponding to each enthalpy value into the database, and directly query the database to determine the ideal fan frequency and water valve during system operation. Ideal opening;

[0038] 2) Update the parameters stored in the database according to the operating conditions of the system. The air supply and exhaust air energy-saving control system includes sensors for measuring the temperature and humidity of the air, and the flow rate of cold slurry water.

[0039] System Tuning Control Process

[0040] Assuming that the optimal operating point o...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com