System and method for optically positioning and measuring level of liquid in transparent container

A transparent container, optical positioning technology, applied in measurement devices, liquid/fluid solid measurement, instruments, etc., can solve the problems of practical impact, no technical solution, too general refraction and reflection in the crescent-shaped area, etc. Small sampling time interval, improve measurement accuracy, and improve the effect of measurement repeatability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0111] Embodiment 1 is to apply the present invention to the positioning and measurement of the liquid level height in a single liquid level pipe.

[0112] The transparent container in embodiment 1 is that single liquid level tube is glass tube 13; Single liquid level tube is glass tube 13; And in order to verify the actual technical effect of the present invention, embodiment 1 was repeated three times, each time using different The glass tube 13; the final experimental results are shown in Table 1.

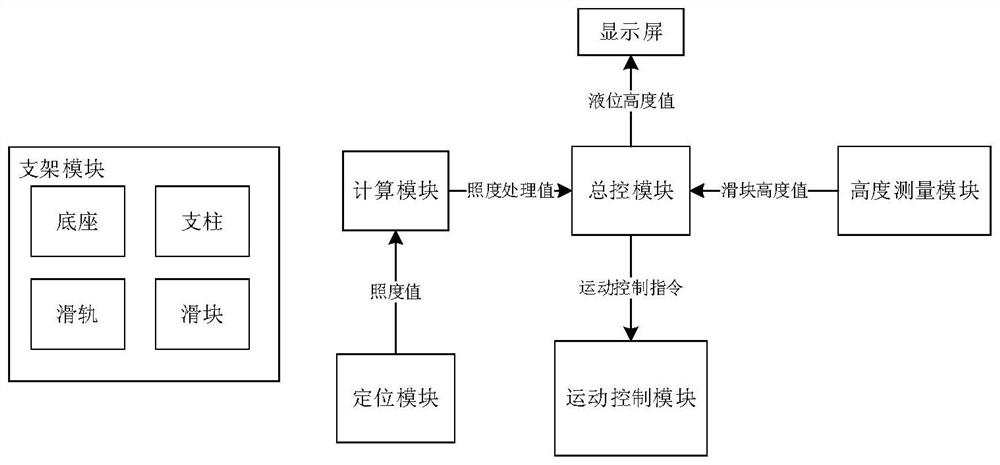

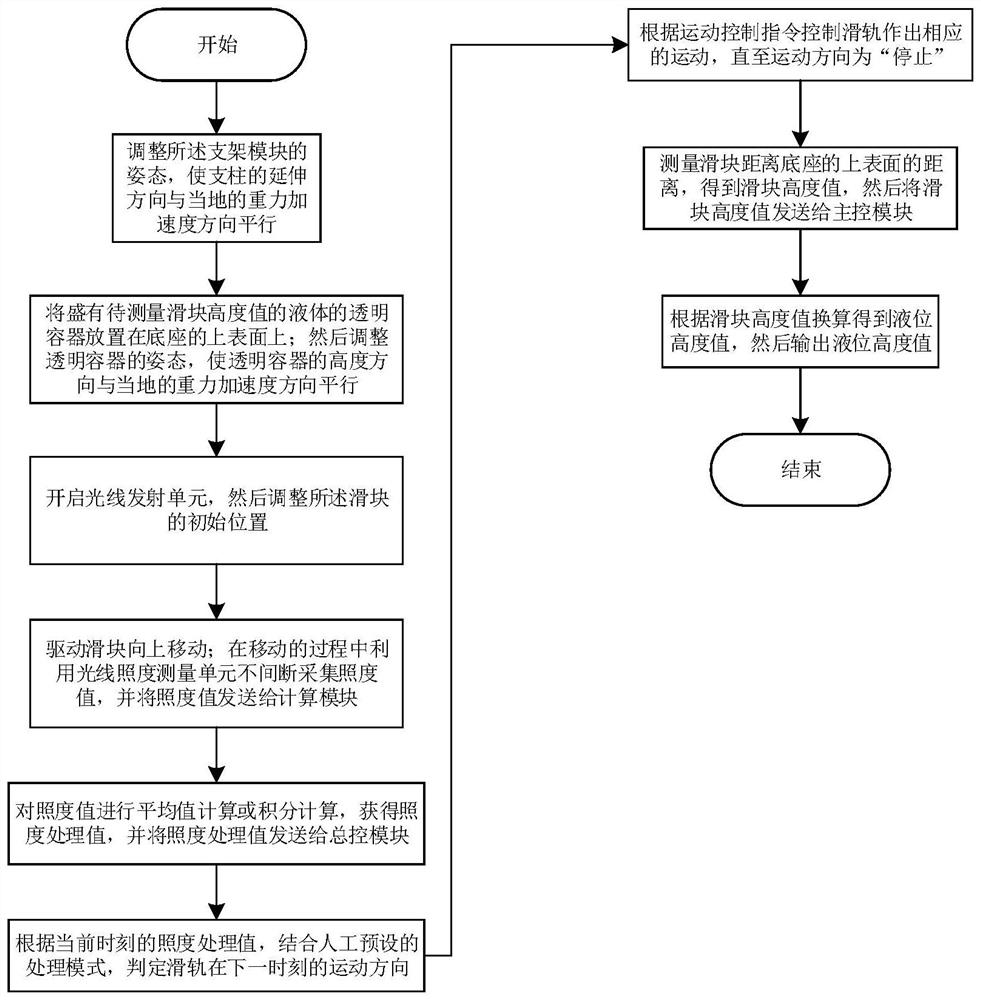

[0113] Such as Image 6 As shown, a system for optically locating and measuring the liquid level in a transparent container consists of the following modules:

[0114] Bracket module: including base 2, pillar, slide rail 4 and slider 3; the pillar is vertically and fixedly installed on the upper surface of the base 2; the slide rail 4 is detachably connected to the pillar, and is on the same side of the base 2 as the pillar; the slide rail 4 The extension direction of the base...

Embodiment 2

[0170] Embodiment 2 is to specifically apply the present invention to liquid level positioning and liquid level height difference measurement in double liquid level pipes.

[0171] The transparent container in Embodiment 2 is a U-shaped glass tube 15 .

[0172] It needs to be explained in advance that the basic principle of optical positioning liquid pressure gauge measurement is to measure the height difference between the two liquid levels, and the pressure difference between the two liquid levels can be calculated and measured by the formula: P=ρ·g·h.

[0173] Such as Figure 7 , Figure 8 with Figure 9 As shown, a system for optically locating and measuring the liquid level in a transparent container consists of the following modules:

[0174] Bracket module: including base 2, pillar, slide rail 4 and slider 3; the pillar is vertically and fixedly installed on the upper surface of the base 2; the slide rail 4 is detachably connected to the pillar, and is on the same si...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com