Method and device for determining oil reservoir foam seepage bubble generation and breaking speed

A technology of bubbles and foams, which is applied in the field of determining the formation and collapse speed of foam seepage bubbles in reservoirs, to achieve accurate calculation results and good oil displacement effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

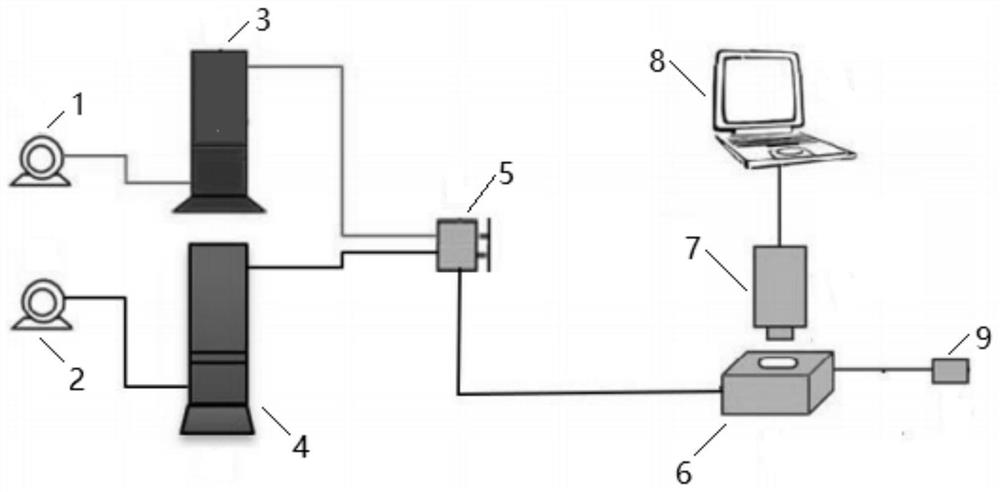

[0043] A device for determining the generation and collapse speed of foam seepage bubbles in reservoirs, including a foam generation unit, a microscopic visualization model, an image acquisition and analysis unit, and a back pressure control device:

[0044] Foam generating unit: including high-precision plunger pump 1, high-precision plunger pump 2, intermediate container A 3, intermediate container B 4 and three-way valve 5, the two inlets of three-way valve 5 are respectively connected to the upper end of intermediate container A3 The interface is connected to the interface on the upper end of the intermediate container B 4 through pipelines, the other end of the intermediate container A 3 is connected to the high-precision plunger pump 1, the other end of the intermediate container B 4 is connected to the high-precision plunger pump 2 2, and the intermediate container A3 contains There is a foam solution, and there is gas in the intermediate container B4; the outlet of the ...

Embodiment 2

[0049] A method for determining the formation and collapse speed of reservoir foam seepage bubbles with the device in embodiment 1, comprising the following steps:

[0050] (1) Foam generation

[0051] Add 2g of Sudan red dyeing agent into 500mL of 0.5% SDS aqueous solution and stir evenly to obtain a dyed foaming agent solution; inject 200mL of dyed foaming agent solution into the intermediate container A3, and pass 200mL of nitrogen gas into the intermediate container B In 4, set the injection speed of the high-precision plunger pump-1 to 25 μL min -1 , set the injection speed of the high-precision plunger pump 2 to 100 μL min -1 , set the pressure of the back pressure control device to 8MPa, and start the high-precision plunger pump 1 and the high-precision plunger pump 2 at the same time, so that the dyed foaming agent solution and nitrogen enter the microscopic visualization model 6 through the outlet of the three-way valve 5 entry port.

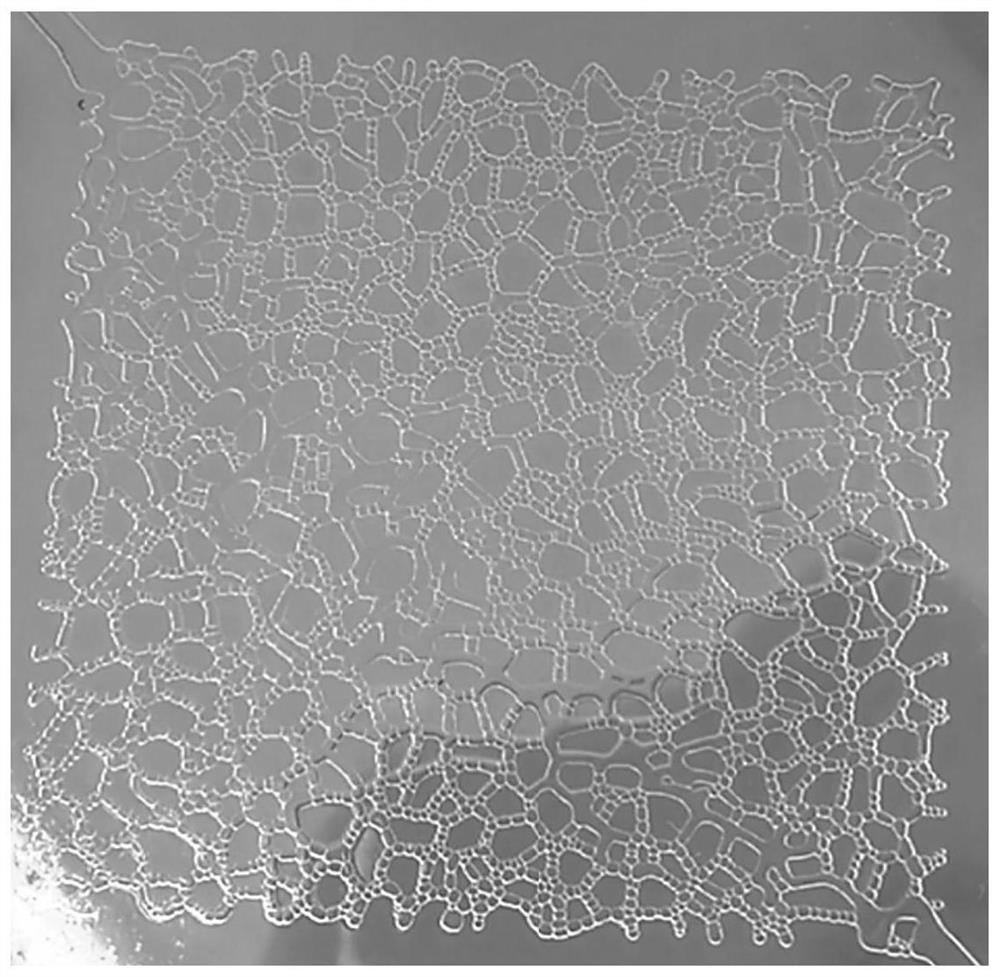

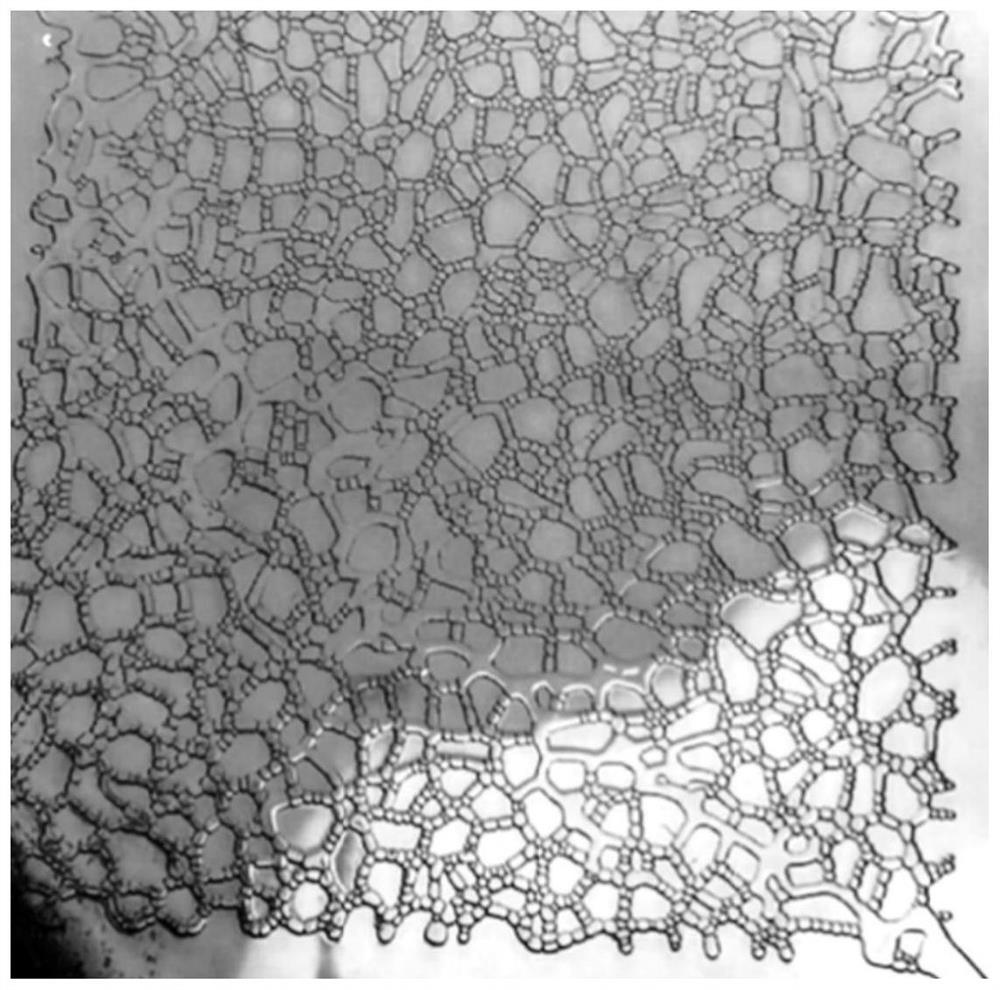

[0052] (2) Foam observation ...

Embodiment 3

[0065] In order to verify that this application can effectively prove the stability of the foam, use the device in Example 1 and the method in Example 2 to record a video with a duration of 120 minutes, take ten time points, calculate the generation and burst speed of bubbles, and then compare with The change trend of the number of bubbles was compared.

[0066] Select a time point every 10 minutes in the video saved in the computer within the time period of 0-120 minutes to take screenshots, and finally obtain 00:10:00, 00:20:00, 00:30:00, 00:40:00 , 00:50:00, 00:60:00, 01:10:00, 01:20:00, 01:30:00, 01:40:00 10 video screenshots. Calculate the number of bubbles at each time point, the total velocity of the bubbles in each time period, and the bubble collapse rate that tends to be stable, and calculate the bubble generation rate in each time period by formula (3). The results are shown in Table 1.

[0067] The number of bubbles at each time point is 2902, 3520, 3292, 2856, 26...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com