Radiographic detection recording, coding and tracing system and working method thereof

A radiographic detection and traceability system technology, applied in typewriters, manufacturing tools, metal processing equipment, etc., can solve the problems of stress caused by the tapping force of thin-walled tubes, heavy steel printing workload, and large workload, etc., to reduce workload, Simple operation and reduced workload

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0032] Below in conjunction with accompanying drawing and embodiment the present invention is described in further detail:

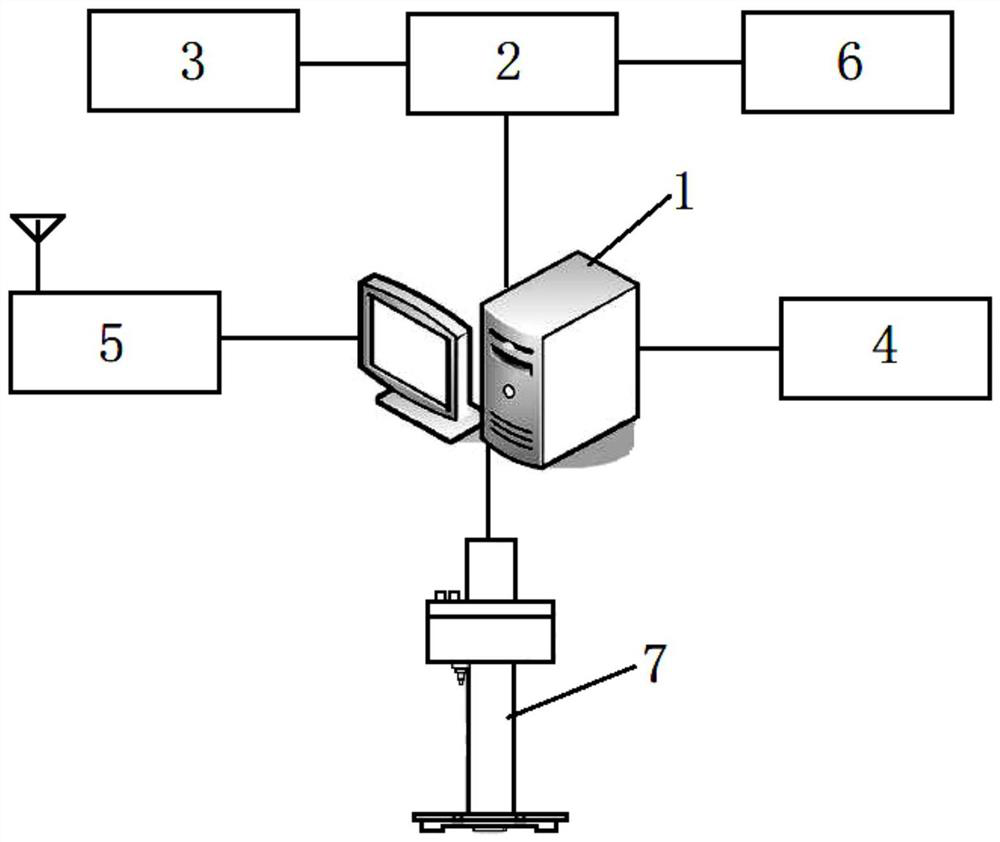

[0033] figure 1 It is a schematic diagram of the overall structure of the radiographic detection record coding traceability system of the present invention, including a processor 1, an encoding module 2, an input and display module 3, a memory module 4, a communication module 5, a welder code management module 6 and a metal coding machine 7 ;

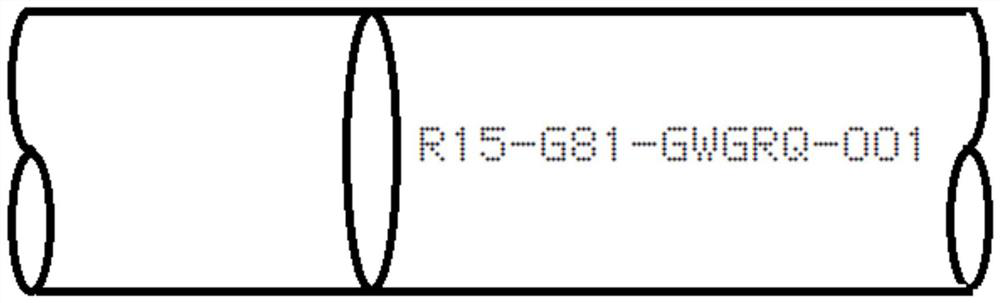

[0034] The processor 1 is respectively connected with the encoding module 2, the memory module 4, the communication module 5 and the metal coding machine 7, and the communication module 5 communicates with the radiation detection system; the encoding module 2 is respectively connected with the input and display module 3 and the welder code management module 6 connected, the coding module 2 is used to generate a unique traceability code corresponding to the radiographic inspection image and containing the welder c...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com