Method for acquiring precise contour of workpiece, machine tool and storage medium

A workpiece and precise technology, applied in the field of workpiece processing equipment, can solve the problems of limited accuracy, difficulty in detecting the error of workpiece contour shape, complicated programming, etc., and achieve the effects of reducing material waste, saving money, precision and cost.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

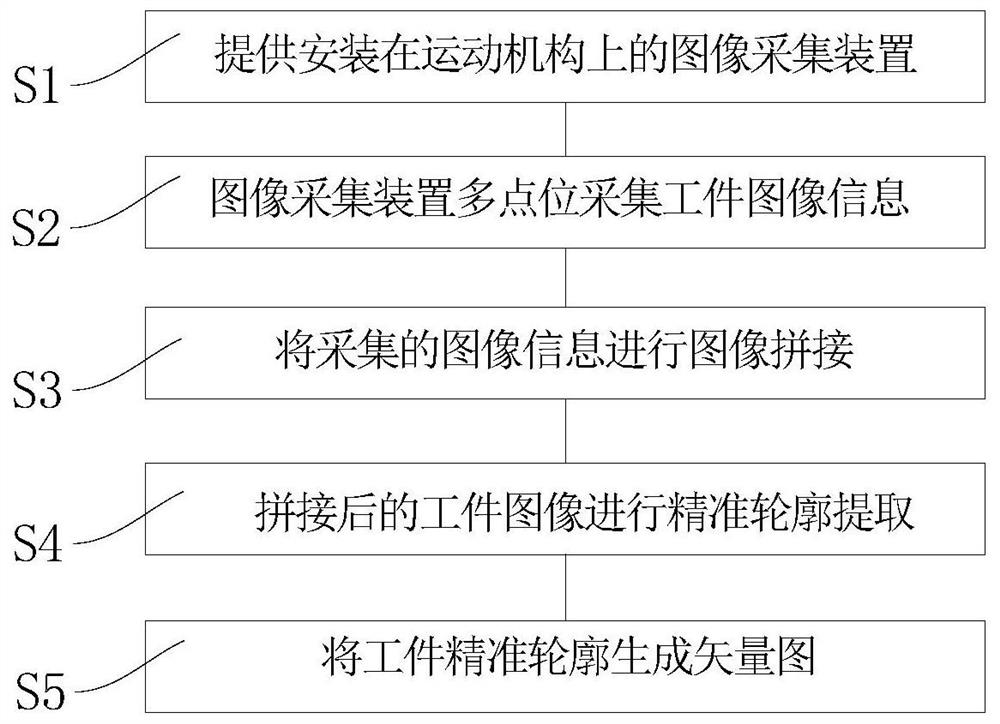

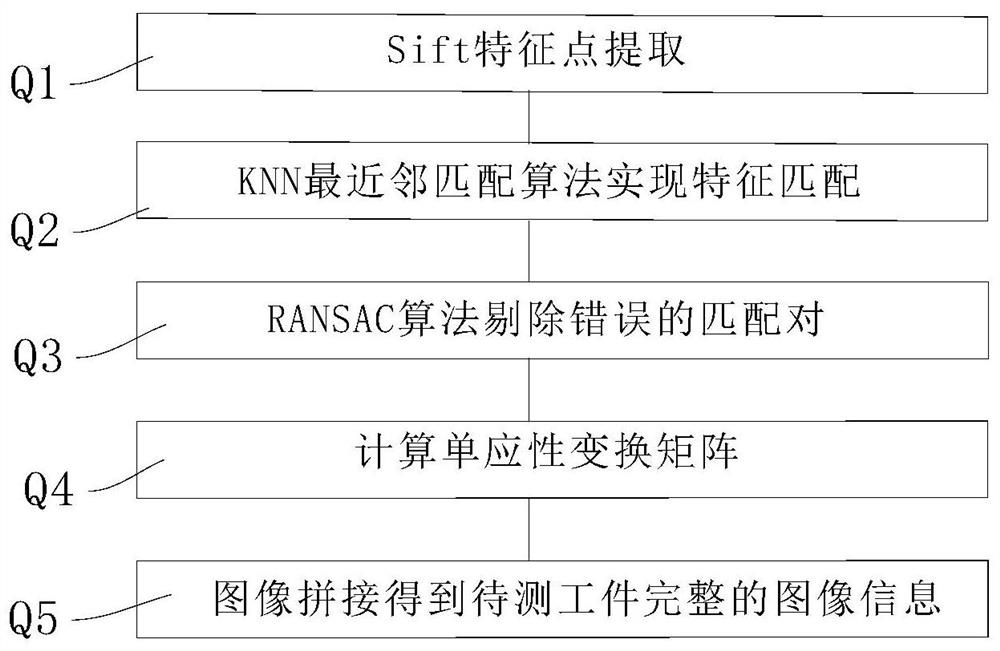

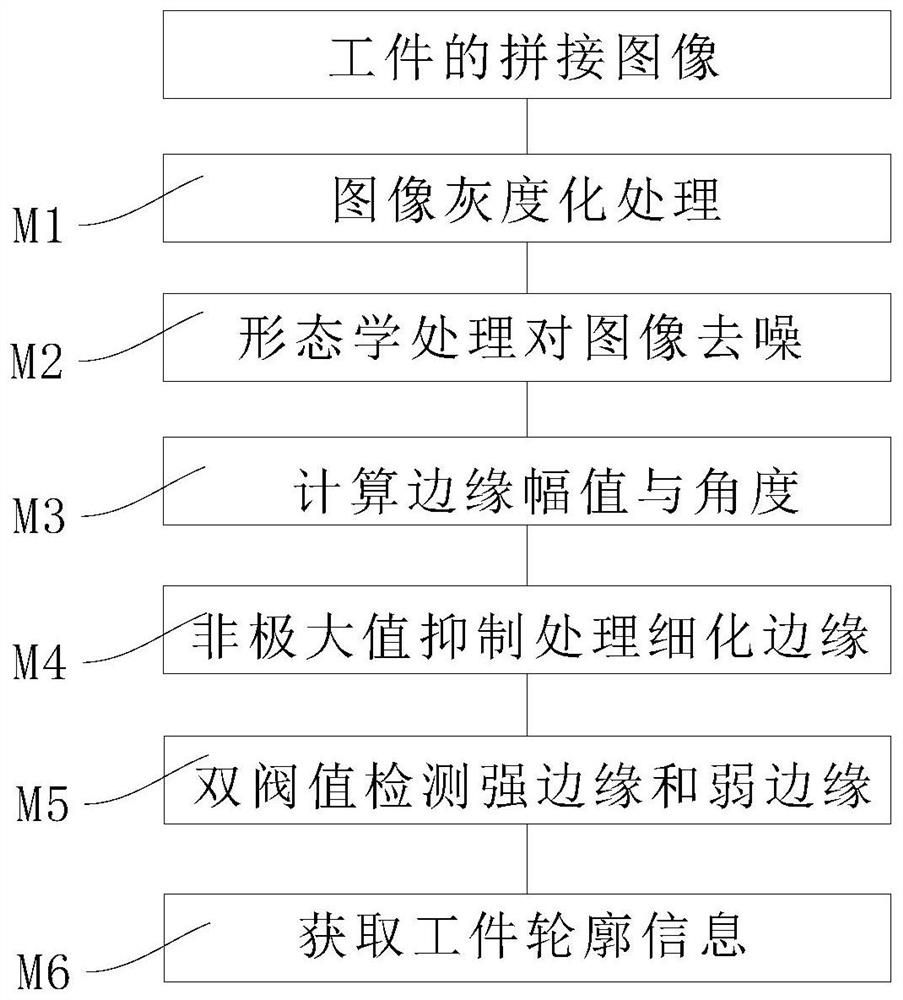

[0068] A method for obtaining an accurate profile of a workpiece: comprising the following steps:

[0069] S1: Provide an image acquisition device that is installed on the movement mechanism and moves with the movement of the movement mechanism; the image acquisition device in this embodiment is an industrial camera.

[0070] The specific parameters of the camera in this embodiment are that the field of view of the image is 500mm×500mm, the distance between the camera and the object to be measured is 500mm, and the measurement accuracy of the image should reach 0.05mm; the camera Basler_acA2440-75uc: the frame rate reaches 75fps, the resolution 5 million pixels (2448px×2048px), chip size 8.4mm×7.1mm, chip type CMOS, interface usb3.0, color camera; lens ML-M0822UR: 8mm lens, object distance 580mm, field of view 660×500mm. If the 1 / 5 sub-pixel edge detection algorithm is used, the horizontal measurement accuracy of the workpiece image can reach 0.054mm / px, and the vertical measu...

Embodiment 2

[0096] The difference between this embodiment and Embodiment 1 is that: performing step S5 includes a workpiece image contour smoothing process for eliminating burrs, fractures and unevenness problems in the workpiece contour line, and the smoothing process includes the following steps:

[0097] N1: Analyze the error characteristics of the extracted workpiece contour;

[0098] N2: Detect and eliminate these contour segments with errors;

[0099] N3: Replace multiple line segments fitted by straight lines or arcs with fitted line segments;

[0100] N4: Use B-spline curves to replace multiple line segments that cannot be fitted with straight lines or arcs;

[0101] N5: Obtain a complete and smooth contour line of the workpiece.

[0102] Firstly, analyze the error features of the extracted workpiece contour, and propose a detection method that can identify these error feature information, which is used to detect and eliminate these error contour line segments, and can be fitted...

Embodiment 3

[0104] The difference between this embodiment and Embodiment 2 is that step S1 in this embodiment also includes: setting an industrial light source and a polarizer for illuminating the workpiece to be tested; step S2 also includes: using an industrial light source to unilaterally or multilaterally Irradiate the workpiece to be tested, highlight the edge features of the workpiece to be tested, and reduce the reflection phenomenon of metal workpieces in the imaging occasion of large-sized workpieces; and use the polarizer installed on the lens to reduce or eliminate astigmatism, reflection, glare and other interference role. The combined use of industrial light sources and polarizers can eliminate the reflection phenomenon of the workpiece to a certain extent, and avoid the unfavorable image caused by the reflection of the workpiece on the later image processing. In other embodiments, it is also possible to illuminate from above the workpiece to be tested. This method is to use ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com