Early warning and positioning method and system for key process parameters of dimethyl phosphite

A technology of dimethyl phosphite and process parameters is applied in the field of early warning positioning method and system of key process parameters of dimethyl phosphite, which can solve the problem of affecting the monitoring effect of key process parameters, reduce the production efficiency and consumption of dimethyl phosphite. Time-consuming and labor-intensive problems, to achieve the effect of improving prediction accuracy, prolonging production cycle and improving production efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

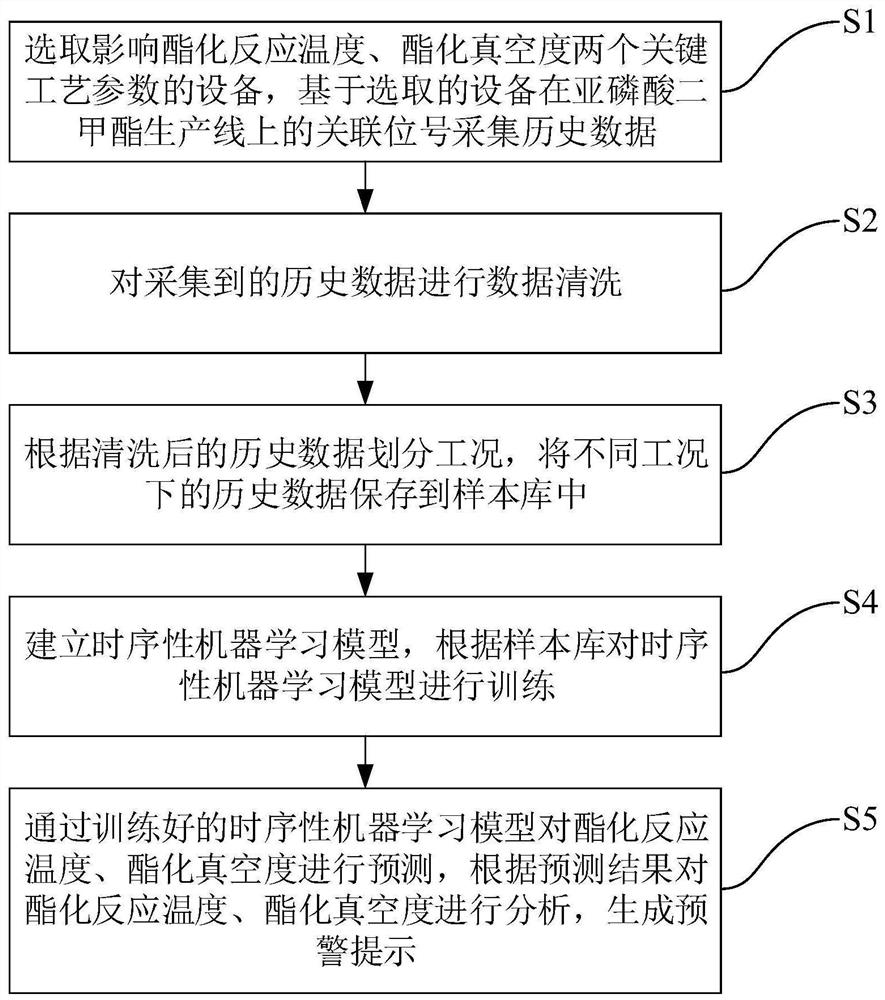

[0056] Such as figure 1 As shown, the present invention proposes a kind of early warning positioning method of dimethyl phosphite key process parameter, comprising:

[0057] S1: Select equipment that affects the two key process parameters of esterification reaction temperature and esterification vacuum degree, and collect historical data based on the associated bit number of the selected equipment on the dimethyl phosphite production line;

[0058] S2: Perform data cleaning on the collected historical data;

[0059] S3: Divide the working conditions according to the historical data after cleaning, and save the historical data under different working conditions in the sample library;

[0060] S4: Establish a sequential machine learning model, and train the sequential machine learning model according to the sample library;

[0061] S5: Predict the esterification reaction temperature and esterification vacuum degree through the trained sequential machine learning model, analyze...

Embodiment 2

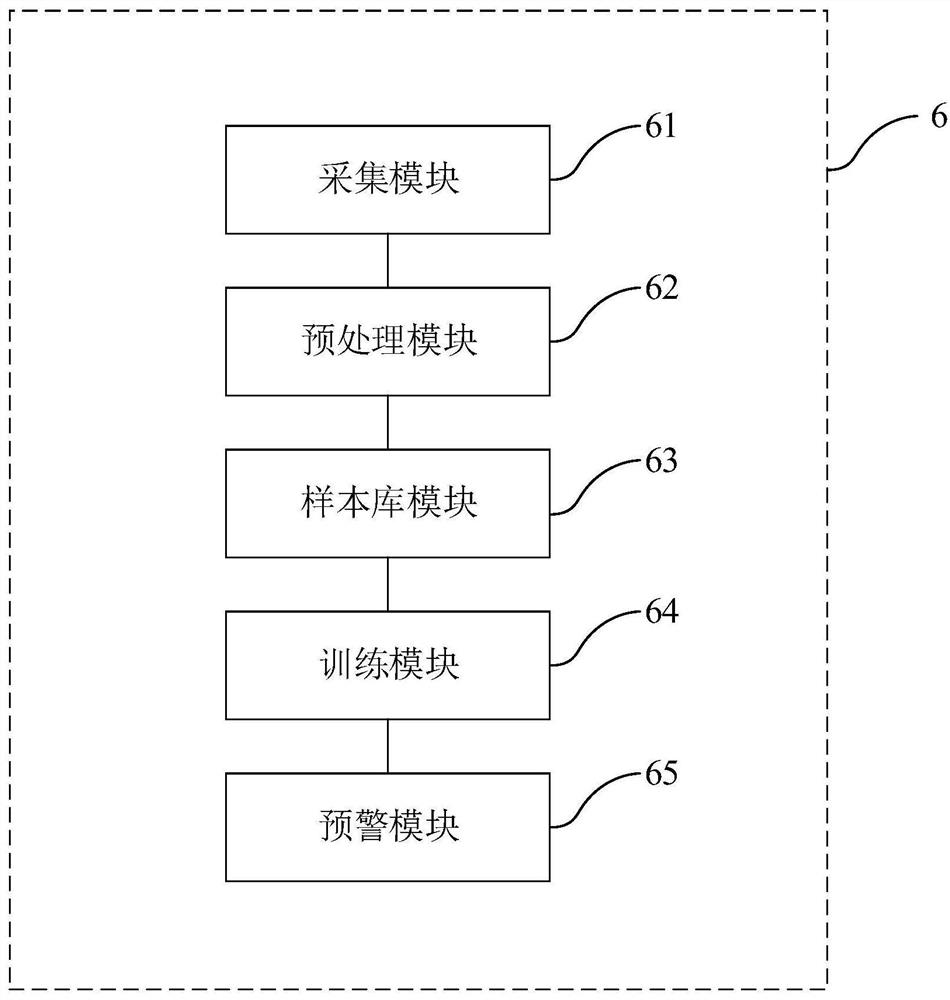

[0100] Such as figure 2 As shown, the present embodiment proposes an early warning positioning system 6 of key process parameters of dimethyl phosphite, including:

[0101] Acquisition module 61: used to select equipment that affects the two key process parameters of esterification reaction temperature and esterification vacuum degree, and collect historical data based on the associated bit number of the selected equipment on the dimethyl phosphite production line;

[0102] Preprocessing module 62: used for data cleaning of the collected historical data;

[0103] Sample library module 63: used to divide the working conditions according to the historical data after cleaning, and save the historical data under different working conditions in the sample library;

[0104] Training module 64: used to establish a sequential machine learning model, and train the sequential machine learning model according to the sample library;

[0105] Early warning module 65: used to predict the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com