Voltage-stabilizing anti-creeping silicon carbide diode

A silicon carbide diode and silicon carbide technology, applied in the field of diodes, can solve problems affecting the voltage stability of Schottky diodes, and achieve the effects of avoiding edge electric field leakage, ensuring voltage stability, and reducing forward voltage drop

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0023] The present invention will be further described in detail below with reference to the examples and drawings, but the implementation of the present invention is not limited thereto.

[0024] like figure 1 Shown:

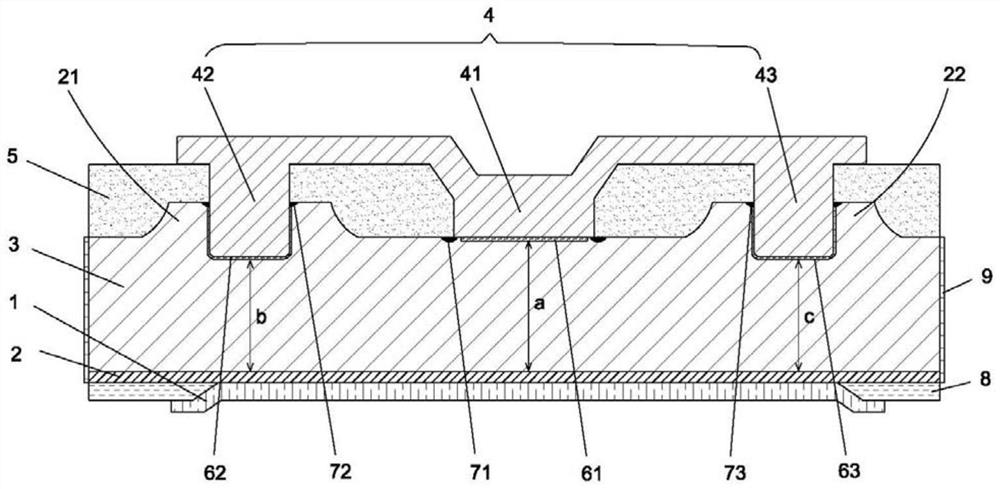

[0025] A voltage-stabilizing and leakage-proof silicon carbide diode, comprising a cathode metal 1, a silicon carbide substrate 2 connected to the upper end of the cathode metal 1, a silicon carbide epitaxial layer 3 formed on the upper end of the silicon carbide substrate 2, and a silicon carbide epitaxial layer connected to the 3 Anode metal at the upper end 4, SiO 2 layer 5;

[0026] The silicon carbide substrate 2 is formed with a first raised portion 21 and a second raised portion 22, the first raised portion 21 is provided with a first groove, and the second raised portion 22 is provided with a second groove;

[0027] The anode metal 4 includes a first contact portion 41, a second contact portion 42, and a third contact portion 43. The first contact po...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com