Light emitting diode

A technology of light-emitting diodes and negative poles, which is applied in the direction of electrical components, circuits, semiconductor devices, etc., can solve the problems of light-emitting diode reliability and shortened life, device failure, rework temperature and tin amount can not be accurately controlled, etc., to improve resistance to high temperature deformation Capability and sealing performance, reduction of product cost and quality cost, and effect of solving the problem of resin cracking

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0037] The present invention will be further described in detail below in conjunction with the accompanying drawings and specific embodiments, but the protection scope of the present invention is not limited thereby.

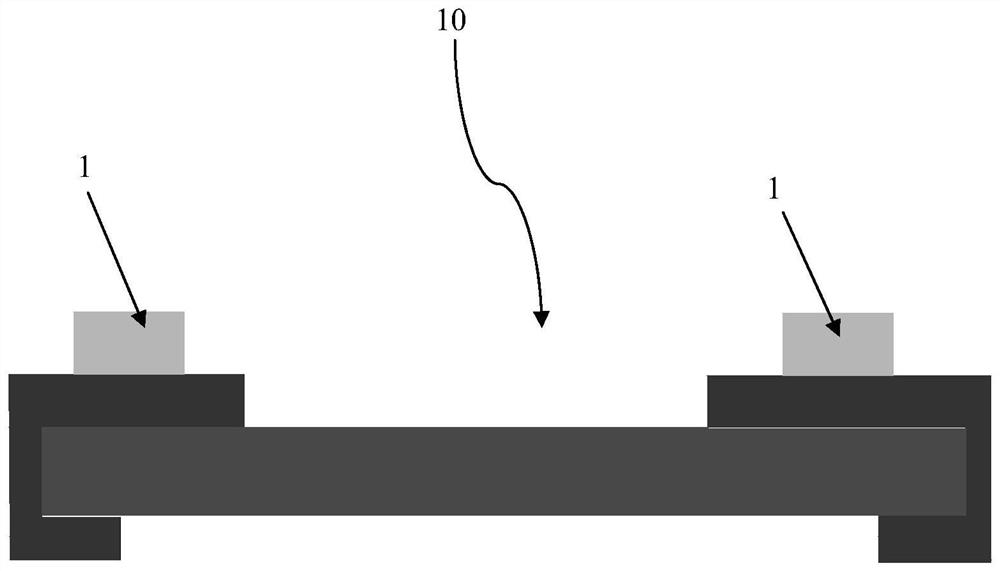

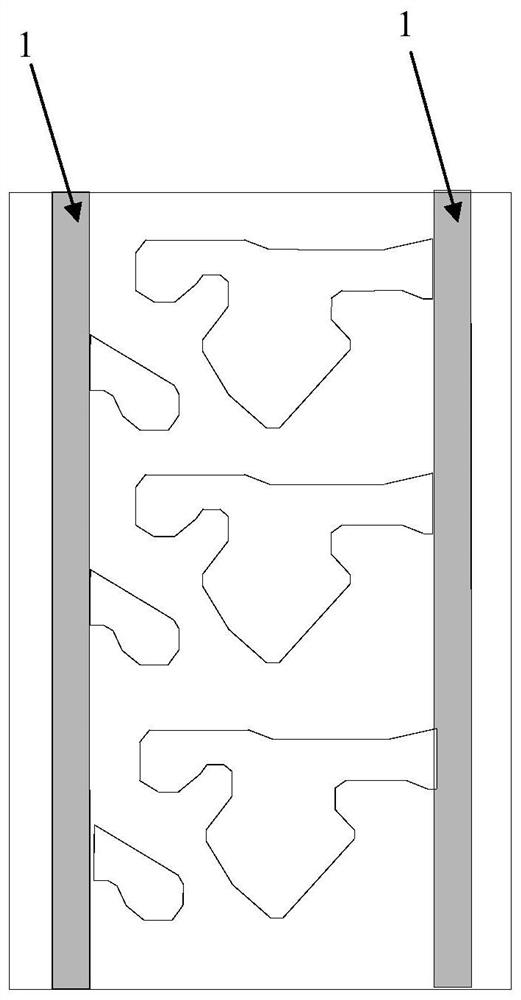

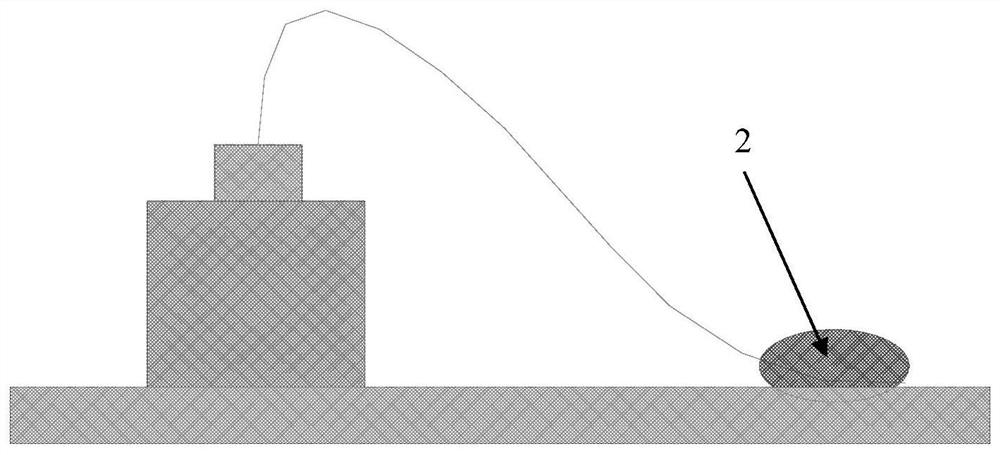

[0038] figure 1 The overall structure of the light emitting diode 10 according to the embodiment of the present invention is schematically shown. figure 2 A printing template of a light emitting diode 10 according to an embodiment of the present invention is schematically shown. image 3 It schematically shows the welding structure of the gold wire in the embodiment of the present invention. Figure 4 It schematically shows the top view structure of the gold wire welding structure in the embodiment of the present invention. Figure 5 It schematically shows the front view structure of the gold wire welding structure in the embodiment of the present invention. Image 6 The overall structure of the light emitting diode 10 according to the embodiment of the pres...

PUM

| Property | Measurement | Unit |

|---|---|---|

| width | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap