Optical module automatic test system and method

A technology of automated testing and testing methods, applied in the field of optical communications, can solve the problems of high error rate and high manpower consumption in manual testing, and achieve the effects of improving testing efficiency, reducing investment, and reducing damage and loss

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0041] In order to make the object, technical solution and advantages of the present invention clearer, the present invention will be further described in detail below in conjunction with the accompanying drawings and embodiments. It should be noted that the words "front", "rear", "left", "right", "upper" and "lower" used in the following description refer to the directions in the drawings, and the words "bottom" and "top "Face", "inner" and "outer" refer to directions toward or away from, respectively, the geometric center of a particular component.

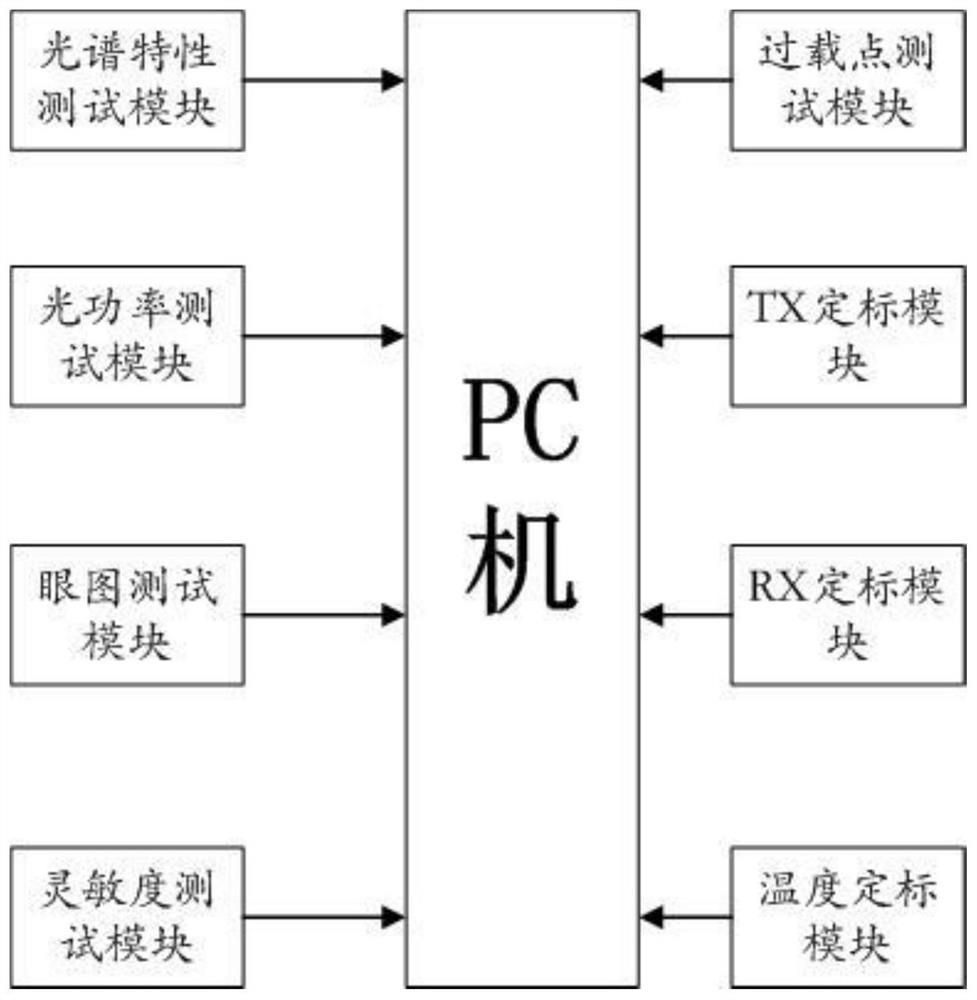

[0042] figure 1 It shows a kind of optical module automatic test system provided by the present invention, including PC, spectral characteristic test module, optical power test module, eye diagram test module, sensitivity test module and overload point test module, said spectral characteristic test module, The optical power test film block, the eye diagram test module, the sensitivity test module, the LOS test module and the ov...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com