Printed circuit board positioning assembly

A printed circuit board and positioning component technology, which is applied in the direction of printed circuit, printed circuit manufacturing, electrical components, etc., can solve the trouble of laying heat transfer paper, the size of printed circuit board is not the same, the feeling of laying is different, etc., to achieve fast The effect of positioning, improving efficiency, and precise positioning

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

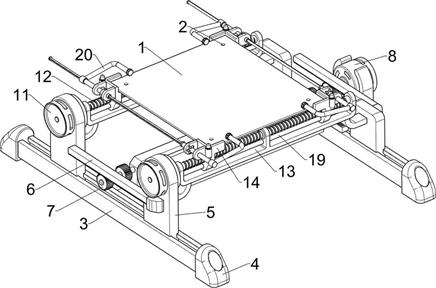

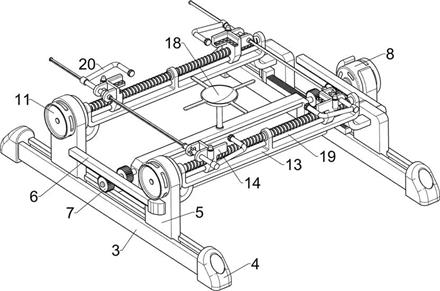

[0036] A printed circuit board positioning assembly includes placement means, such as figure 1 , figure 2 and Figure 4 As shown, the placement device includes a slide block 14, a positioning rod 15, an insulating ring 16 and an insulating pad 17, the slide block 14 is installed on the worm screw 12 and the slide rod 19, and the slide block 14 has a screw thread and a light hole, which are respectively connected to the worm screw 12 and the slide rod 19. The slide bar 19 is corresponding, so that the slide block 14 can move back and forth with the rotation of the worm screw 12, the positioning rod 15 and the insulating pad 17 are fixed above the slide block 14, and the diameter of the positioning rod 15 is smaller than the diameter of the positioning hole 2 on the printed circuit board 1, And the upper end is provided with a chamfer, so that the printed circuit board 1 can be inserted better, the insulating ring 16 is sleeved on the positioning rod 15, and is used to place t...

Embodiment 2

[0038] Embodiment 2: The difference from Embodiment 1 is that when the printed circuit board 1 is a special-shaped board, the printed circuit board 1 cannot be fixed and positioned by the four corners, so the slider 14 can be adjusted so that the positioning rod 15 is aligned with the positioning hole on the printed circuit board 1 2, the positioning hole 2 on the printed circuit board 1 can be set in the positioning rod 15, so that the printed circuit board 1 is placed on the insulating ring 16, and the printed circuit board 1 is fixed and positioned, which is convenient for pasting the thermal transfer paper.

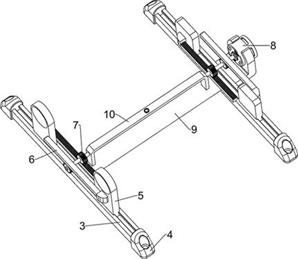

[0039] A printed circuit board positioning assembly includes a lifting device, such as figure 2 As shown, the lifting device is composed of a tray 18, which is fixed on the second mounting plate 10. The upper surface of the tray 18 is 2 mm higher than the placement plane of the placement device, so that the placement device will not bump into the printed circuit board...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com