Vapor phase growth device and carrier used in same

A gas phase and carrier technology, which is applied in the field of carriers, can solve the problems of being unable to suppress the sharp change of the film thickness of the epitaxial film formed on the single crystal silicon wafer, and the difficulty of flattening the peripheral edge, so as to suppress the unevenness of the film thickness, The effect of uniform film thickness

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

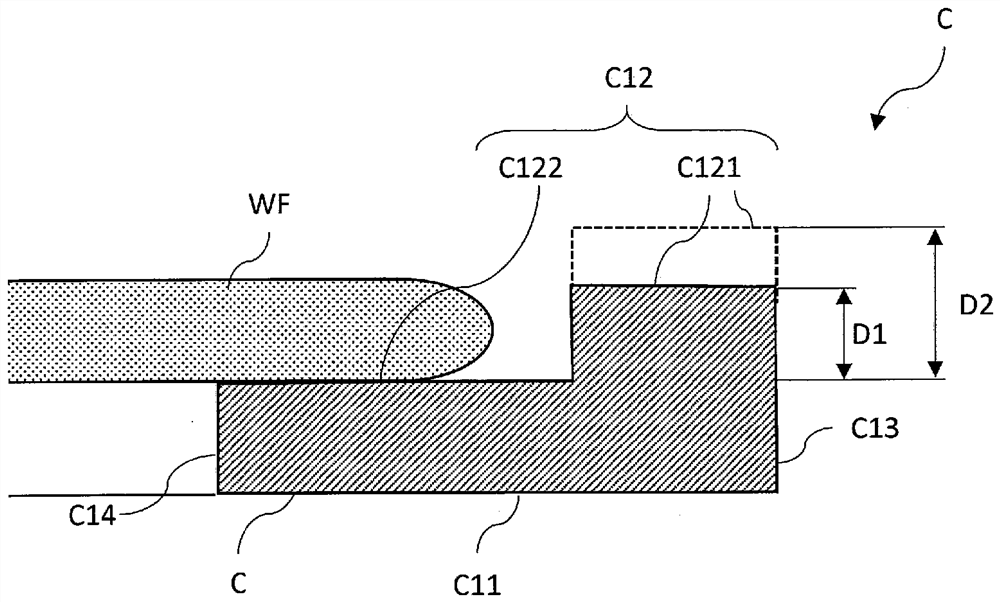

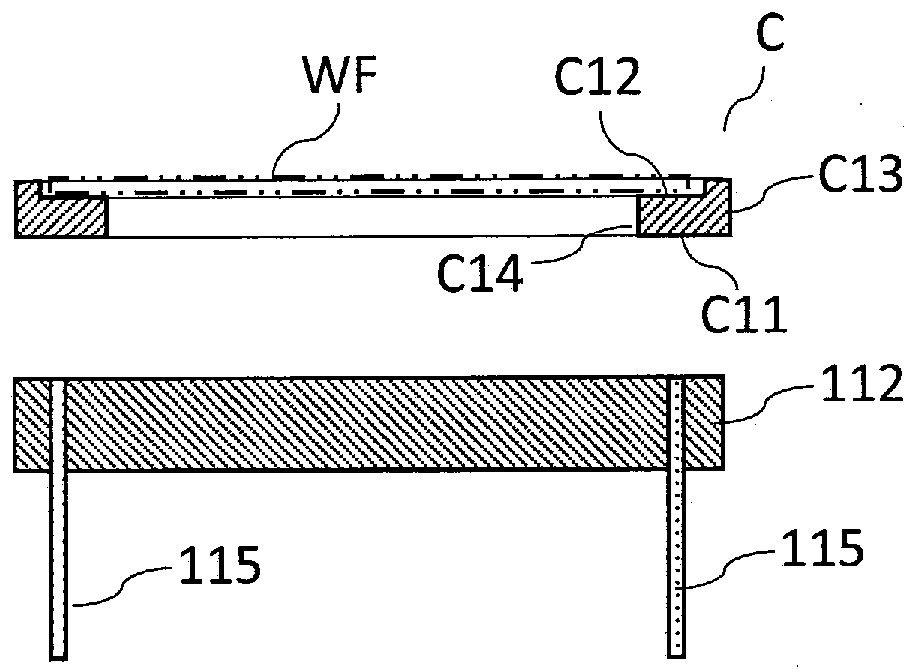

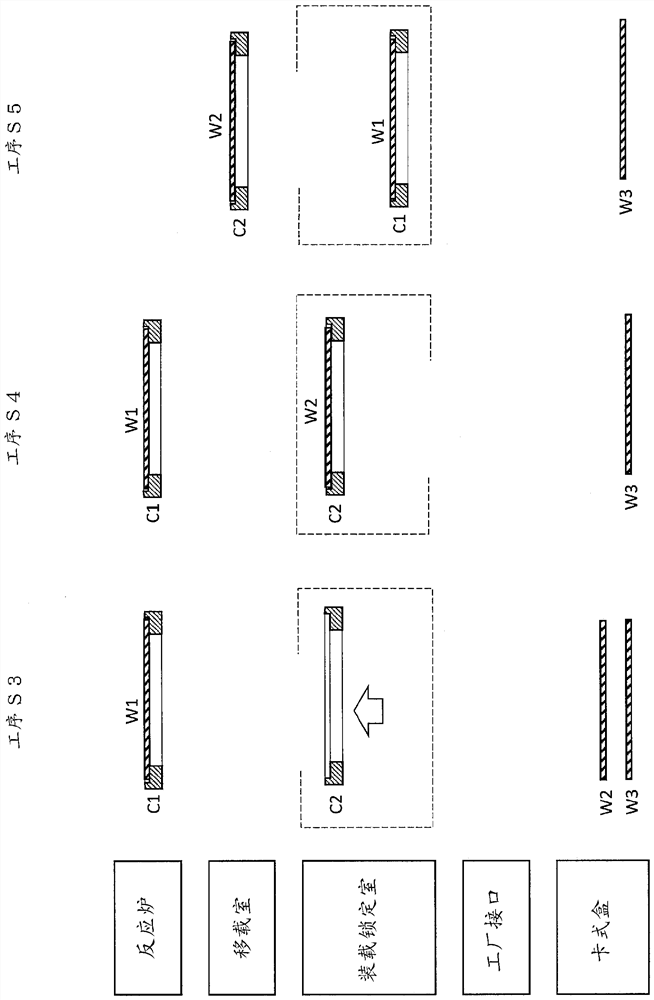

[0049] Embodiments of the present invention will be described below based on the drawings. figure 1It is a block diagram showing the vapor phase growth apparatus 1 according to the embodiment of the present invention, and the main body of the vapor phase growth apparatus 1 shown in the center is shown in plan view. The vapor phase growth apparatus 1 of this embodiment is a so-called CVD apparatus, and includes a pair of reaction furnaces 11, 11, a wafer transfer chamber 12 provided with a first robot 121 for processing a wafer WF such as a silicon single crystal wafer, and a The load lock chamber 13, the factory interface 14 provided with the second robot 141 processing the wafer WF, and the load port of the wafer storage container 15 (cassette) storing a plurality of wafers WF are provided.

[0050] The factory interface 14 is an area having the same atmosphere as that of the clean room where the wafer container 15 is placed. The factory interface 14 is provided with a secon...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com