Aerator for generating aerated liquid stream

A technology of jet regulator and liquid jet, which is applied in indoor sanitary pipeline installations, buildings, water supply installations, etc., can solve problems such as leakage, and achieve the effect of reducing the risk of leakage

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

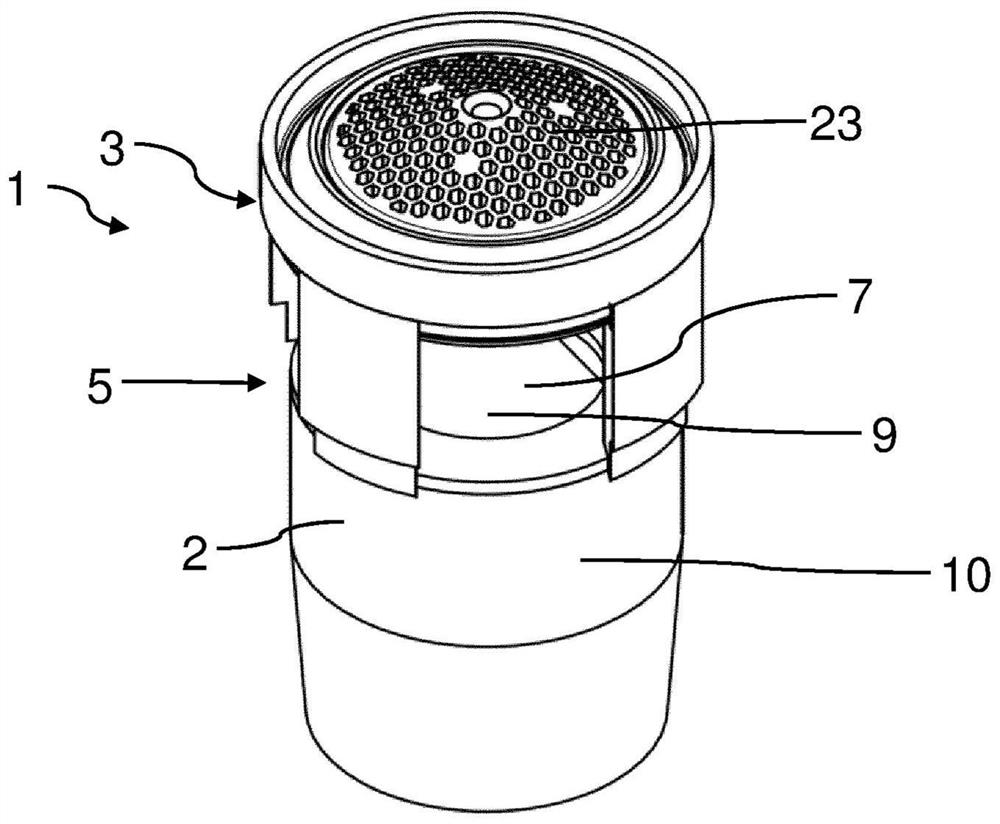

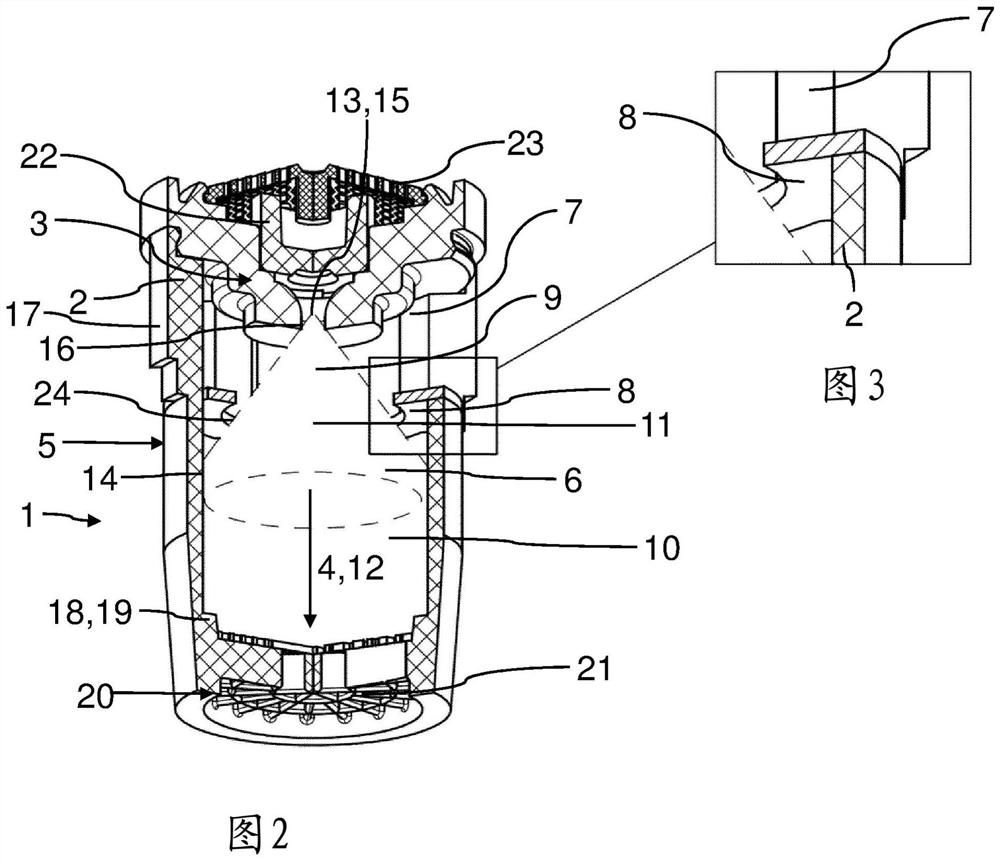

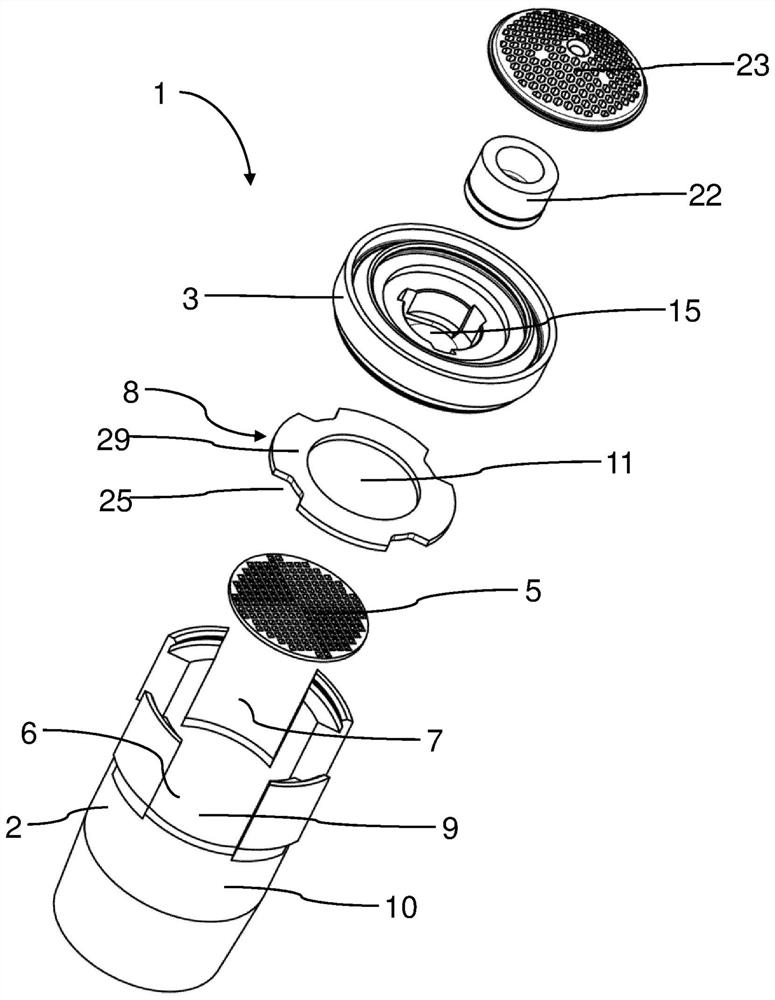

[0036] exist figure 1 , 2 , 4, 5, 6, 8 and 9 show three embodiments of the jet regulator, generally designated 1 . The jet regulator 1 is provided for generating an aerated liquid jet.

[0037] The jet regulator 1 has a housing 2 via which the jet regulator 1 can be connected to a jet regulator receptacle of a sanitary fitting. For this purpose, a coupling point can be formed on the outside of the housing 2 , which can be connected to a corresponding mating coupling point of the sanitary outlet fitting.

[0038] A jet acceleration device 3 is arranged or formed inside the housing 2 . The jet acceleration device 3 is provided to break up the jet flowing into the jet acceleration device 3 into a plurality of separate liquid fractions.

[0039]A screen 23 can be arranged on the inflow side upstream of the jet acceleration device 3 .

[0040] A jet aeration device 5 is provided downstream of the jet acceleration device 3 in the flow direction 4 (of the liquid flowing through ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com