Food rolling method and device

A technology for making rolls and food, applied in transportation and packaging, conveyor control devices, confectionery, etc., can solve the problems of high labor intensity, complex structure, poor use effect, etc., to reduce labor intensity, improve work efficiency, Cleverly designed effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0027] The present invention will be further described below in conjunction with embodiment:

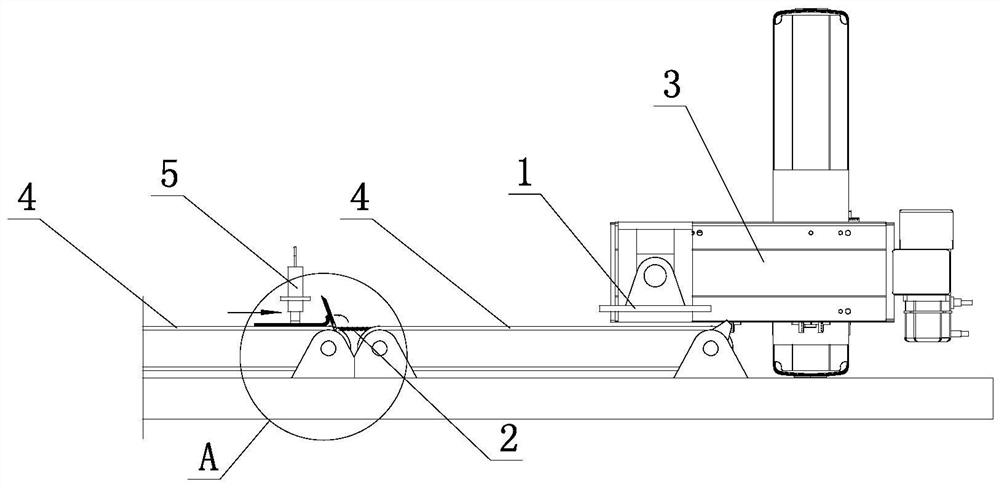

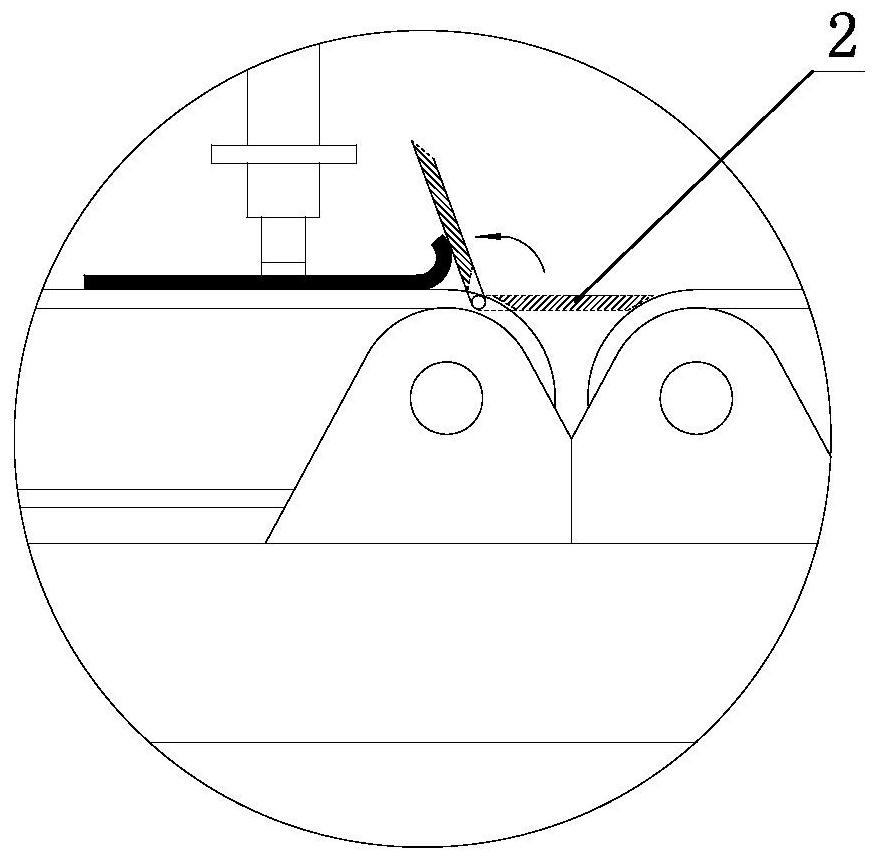

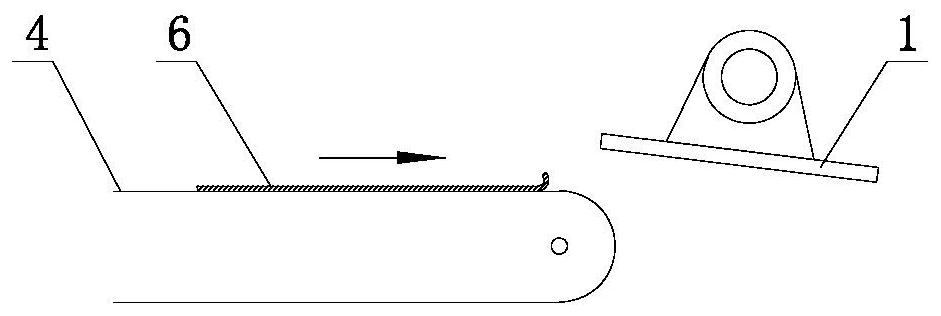

[0028] In the food rolling method described in the present invention, the auxiliary rolling device 2 firstly folds the front end of the sheet food 6 to form a core, and then the sheet food 6 is placed in the upper and lower working parts of the rolling device. Between the surfaces, the sheet food 6 is twisted into rolls under the action of the upper and lower working surfaces moving towards each other.

[0029] Wherein, during the rolling process, the upper and lower working surfaces of the rolling device can always be parallel to each other, and the distance between the upper and lower working surfaces increases with the change of the diameter of the rolled food. During the process, the upper working surface is in contact with the roll food all the time until the sheet food 6 is completely twisted into a roll.

[0030] Another embodiment of the roll forming method is: during the ro...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com