Metal part polishing device

A technology for metal parts and fixing devices, which is applied in the field of metal parts grinding devices, can solve the problems of inability to maintain the pressure between metal parts and sandpaper, affect the grinding effect, and low grinding efficiency, and achieve convenient fixing of sandpaper, high grinding efficiency, installation and disassembly convenient effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

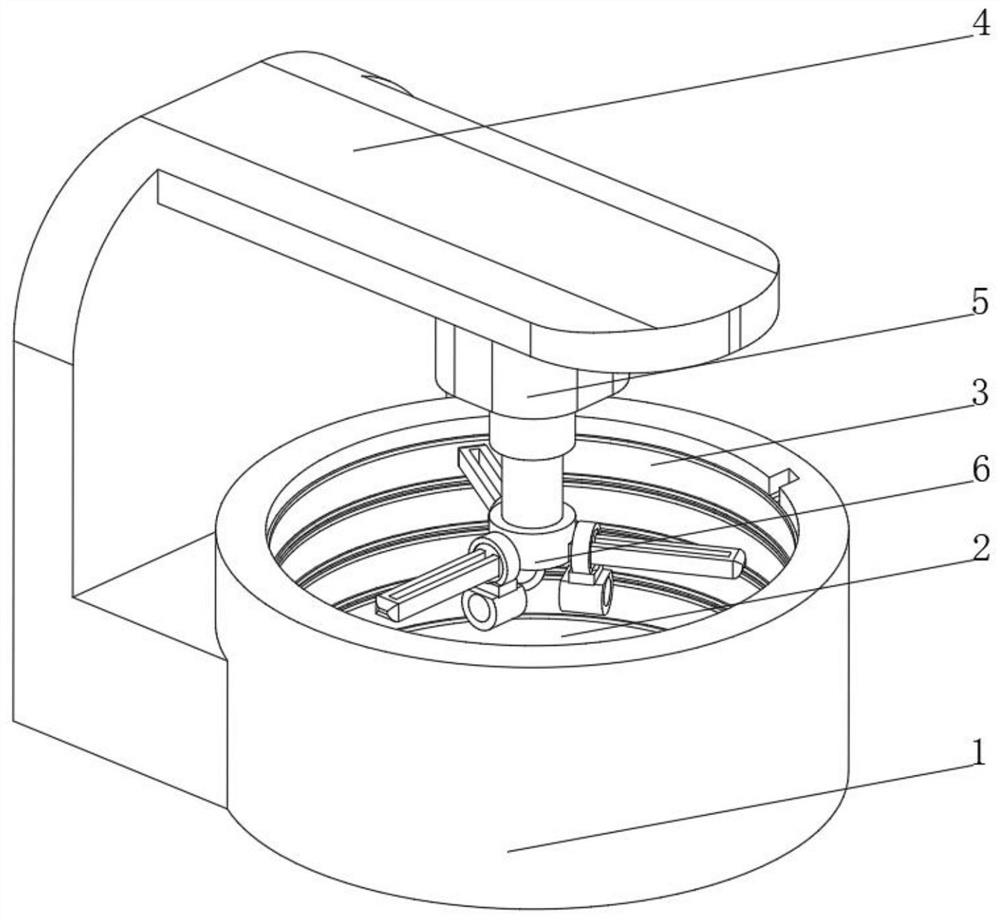

[0039] see Figure 1-2 , the present invention provides a technical solution: a metal piece grinding device, specifically comprising:

[0040] A fixed base 1, the top of the fixed base 1 is provided with a grinding groove 2, and a fixing device 3 arranged inside the grinding groove 2, and the fixing device 3 is slidingly connected with the inner wall of the grinding groove 2;

[0041] A support frame 4, the support frame 4 is arranged on one side of the fixed base 1, the top of the support frame 4 is fixedly connected with a driving device 5, and the bottom of the driving device 5 is connected with a polishing device 6 through a telescopic rod;

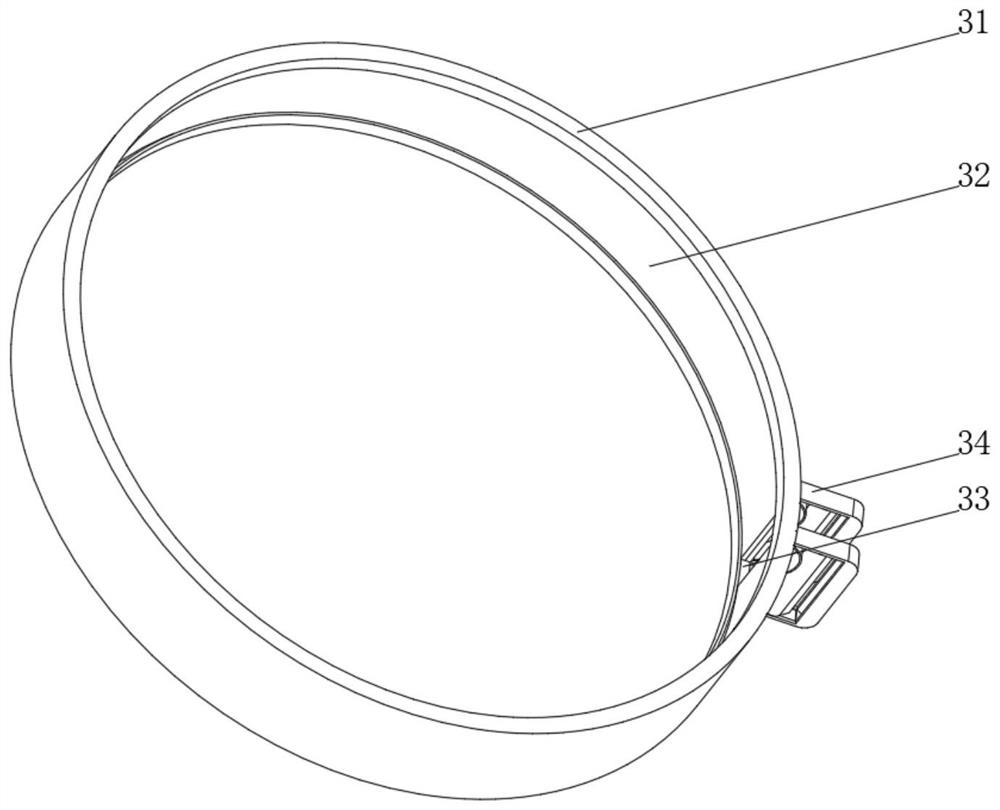

[0042] Fixture 3 includes:

[0043] Fixed ring 31, the inner wall of the fixed ring 31 is provided with a limit slideway 32, one side of the fixed ring 31 is provided with an entrance 33, both sides of the entrance 33 are provided with a clamping device 34, and the top of the limit slideway 32 inner wall side is provided with a tilti...

Embodiment 2

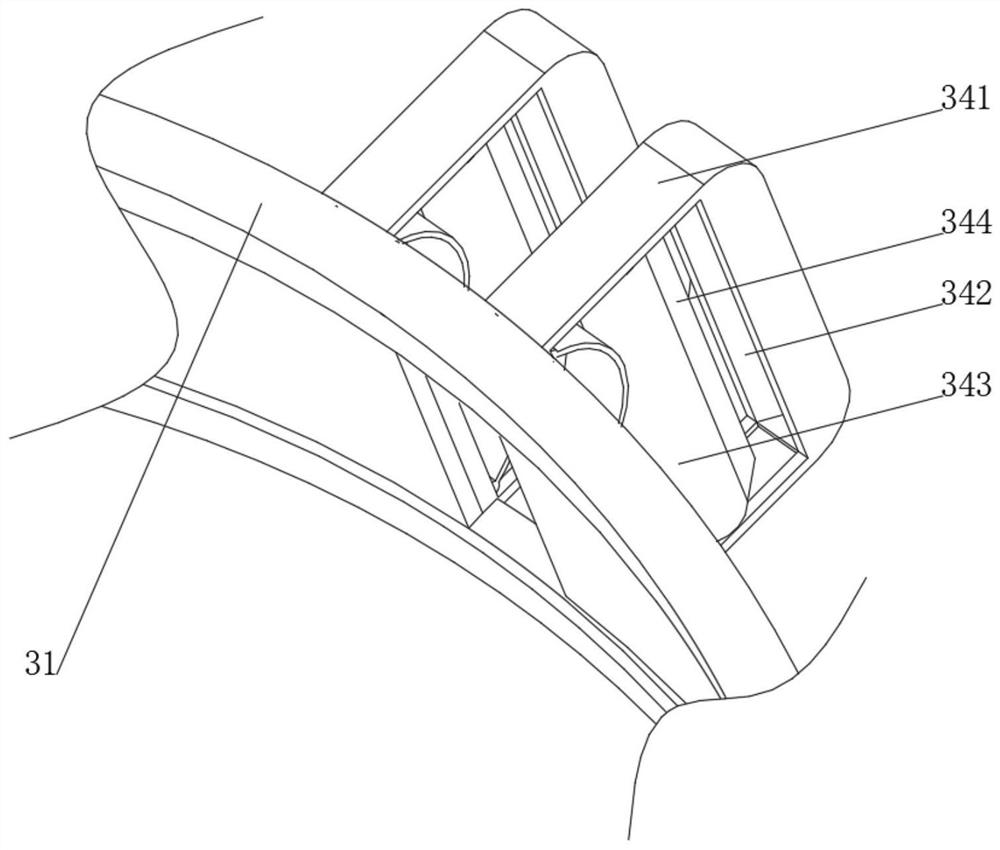

[0046] see Figure 1-3 , on the basis of Embodiment 1, the present invention provides a technical solution: the inner wall of the grinding tank 2 is provided with a chute compatible with the clamping device 34, and the clamping device 34 includes:

[0047] The fixed frame 341, one side of the fixed frame 341 is fixed on the side of the entrance 33 on the fixed ring 31, and the inner wall side of the fixed frame 341 is provided with a clamping groove 342;

[0048] Clamping rod 343, one side of the clamping rod 343 is fixedly connected to one side of the inner wall of the fixed frame 341 through an arc spring, and the side of the clamping rod 343 away from the arc spring is provided with a clamping groove 342 suitable for clamping. Block 344.

[0049] Both the bottom and the bottom of the inner wall of the fixing frame 341 are provided with limiting grooves compatible with the clamping rod 343, and both ends of the clamping rod 343 extend to the inside of the limiting groove an...

Embodiment 3

[0052] see Figure 1-4 , on the basis of Embodiment 1 and Embodiment 2, the present invention provides a technical solution: the grinding device 6 includes a fixed disc 61, and the side of the fixed disc 61 is fixedly connected with a slide bar 62, and the slide bar 62 is provided with a chute 63 for fixing The disk 61 is sleeved and slidably connected with a rotating device 64, the bottom of the rotating device 64 is fixedly connected with a clamp 65, the top of the fixed disk 61 is fixedly connected with the telescopic rod at the bottom of the driving device 5, and the sliding rods 62 are arranged in three groups and evenly distributed on the fixed disk. 61 sides.

[0053] When the grinding device 6 rotates, the fixed disk 61 drives the slide bar 62 to rotate, and the slide bar 62 drives the metal parts on the clamp 65 to rotate through the rotating device 64. One end slides, and at the same time drives the metal parts inside the fixture 65 to be compressed on the sandpaper...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com