Methanol fuel containment system and ship

A methanol fuel and methanol technology, applied in the field of ships, can solve problems such as pipeline corrosion, blockage or damage of heat exchangers, pumps and fuel injectors, and inability to deal with methanol fuel impurities, so as to ensure normal operation and avoid pipeline corrosion Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

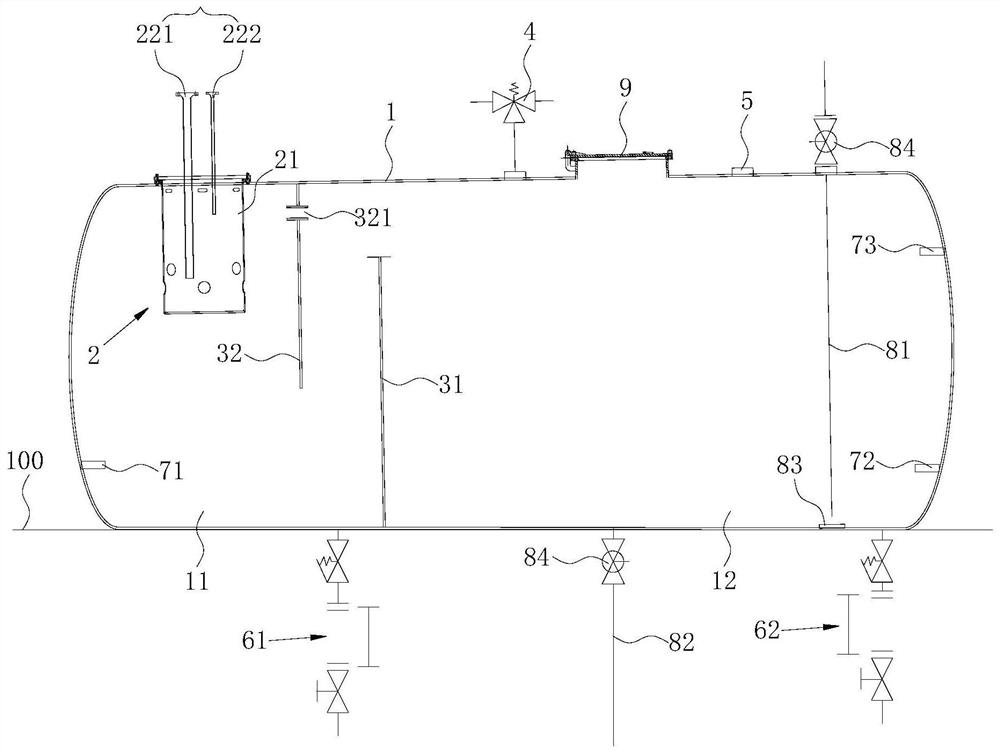

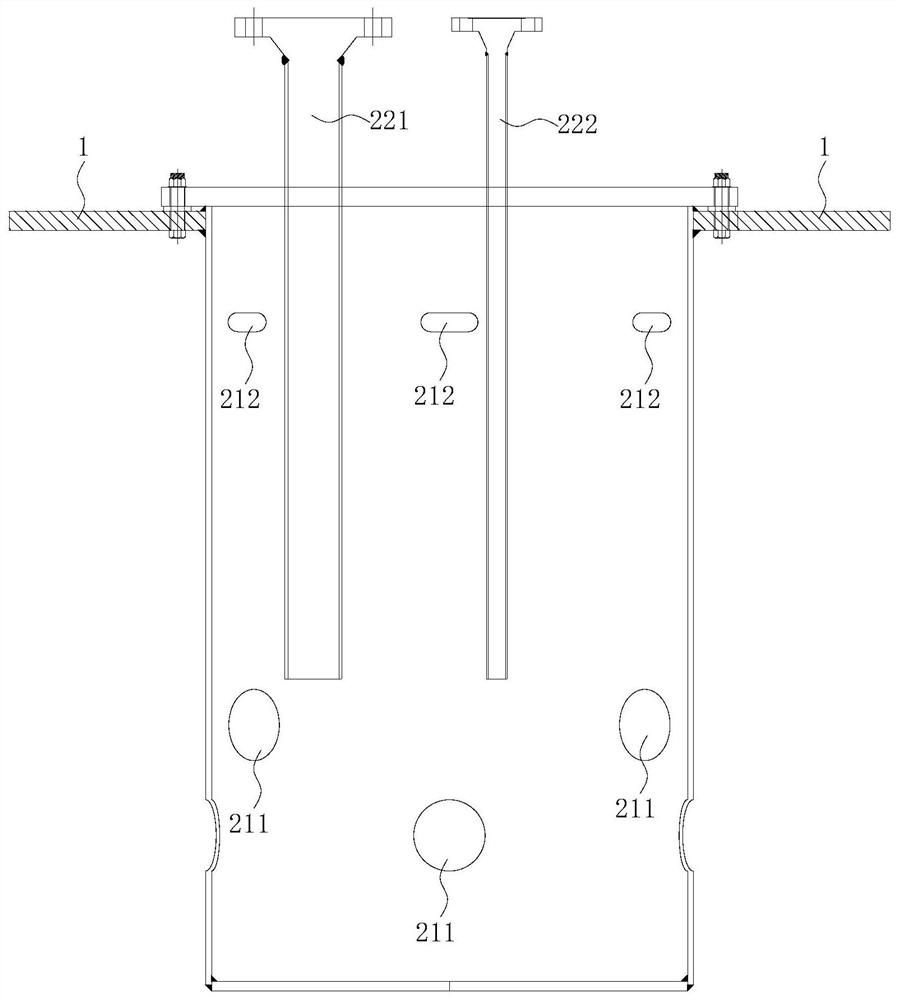

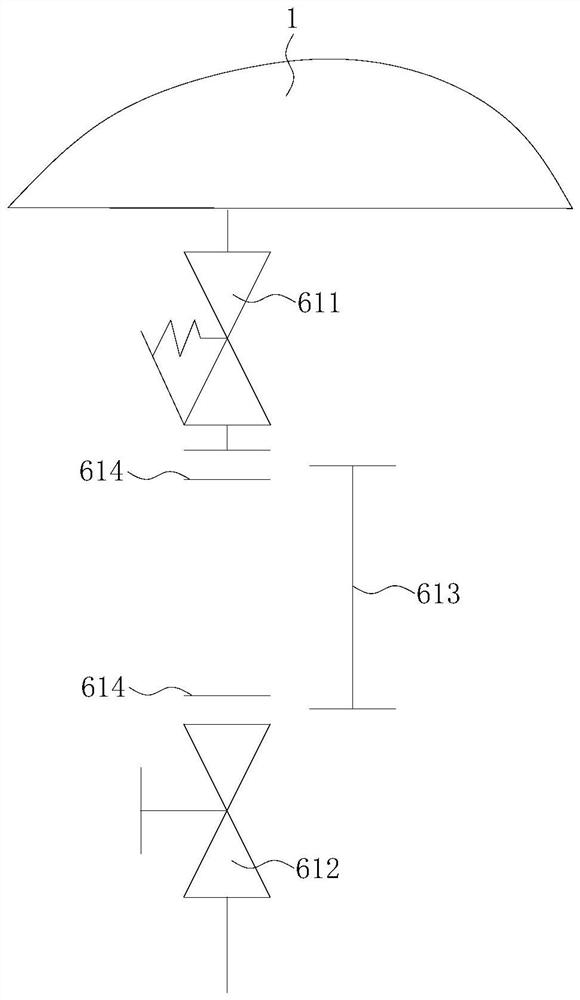

[0022] The technical solutions of the present invention will be further described below in conjunction with the accompanying drawings and through specific implementation methods.

[0023] In the present invention, unless otherwise clearly specified and limited, a first feature being "on" or "under" a second feature may include direct contact between the first and second features, and may also include the first and second features Not in direct contact but through another characteristic contact between them. Moreover, the first feature being "on" the second feature includes the first feature being directly above and obliquely above the second feature, or simply means that the first feature is horizontally higher than the second feature. "Below" the first feature below the second feature includes that the first feature is directly below and obliquely below the second feature, or simply means that the level of the first feature is smaller than that of the second feature.

[0024...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com