Roof waterproof heat-insulation and heat-preservation decoration structure integrated system

A technology for thermal insulation and decorative structure, applied in the direction of roofing, roof decoration, roof covering, etc., can solve the problems of affecting indoor living comfort, poor thermal insulation effect, etc., and achieve good connection stability and connection strength, long-term The effect of long service life and good impact strength

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

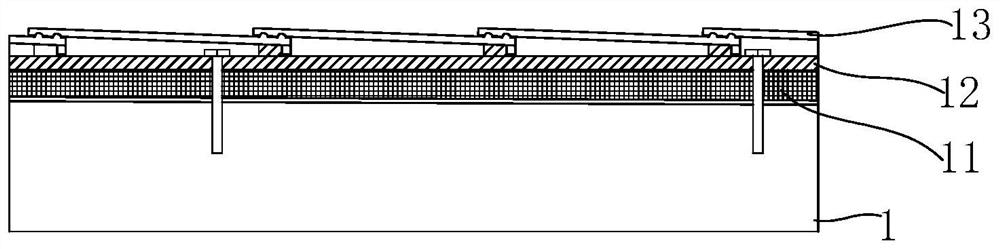

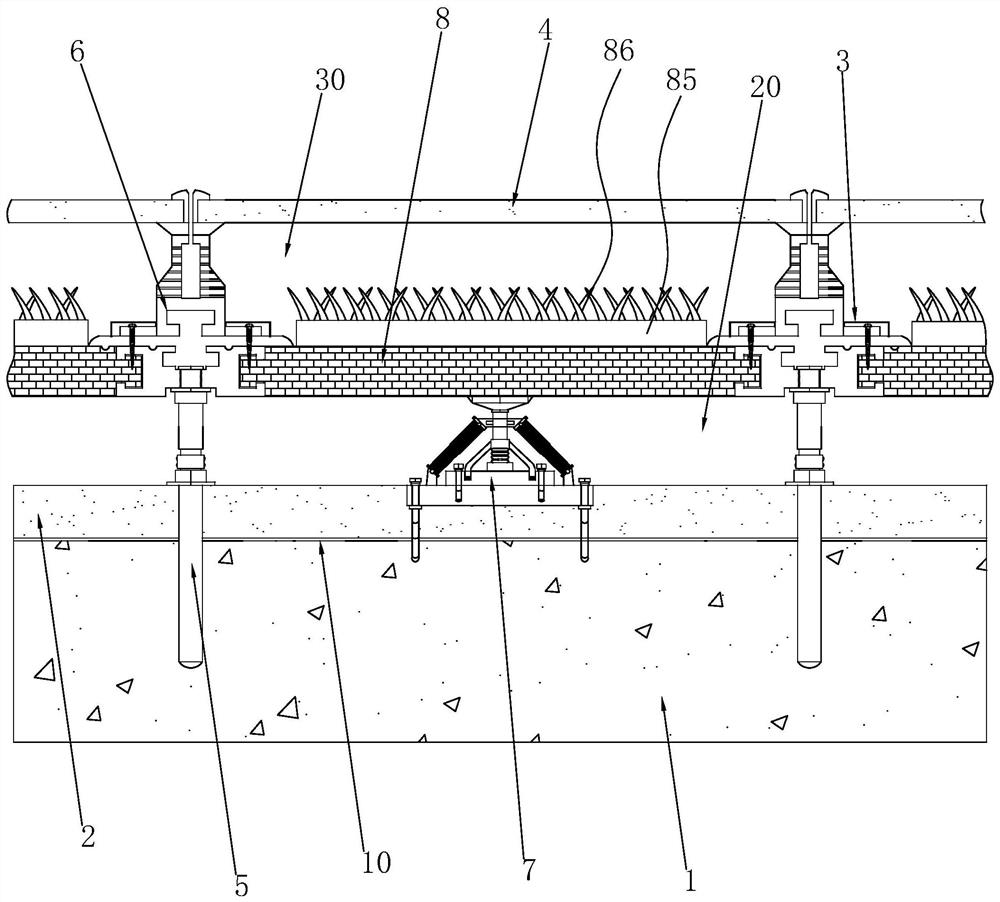

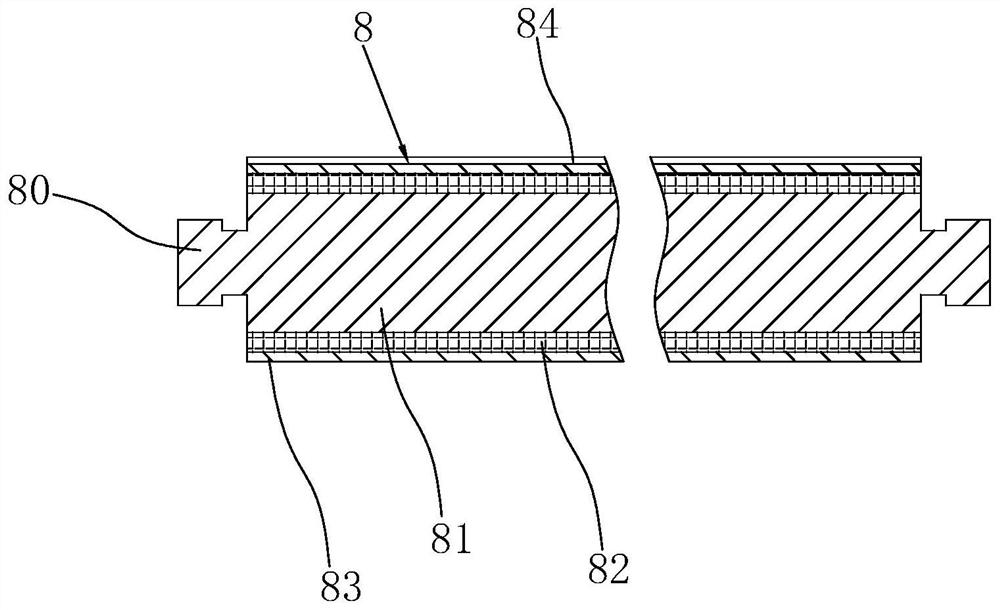

[0040] refer to figure 2 , is an integrated roof waterproof, thermal insulation and decorative structure system disclosed in this application, including roof surface layer 1, waterproof silicone rubber, waterproof cloth layer 10, thermal insulation cement mortar layer 2, thermal insulation component 3, and tempered glass layer 4. The roof surface 1 needs to fill the cracks before laying the waterproof cloth layer 10 to enhance the overall waterproof performance. The specific construction operation is as follows: use waterproof silicone rubber to fill the cracks in the roof surface 1, and use sandpaper to polish the roof surface after the waterproof silicone rubber is cured 1. After removing excess waterproof silicone rubber, the waterproof cloth layer 10 can be laid on the roof surface layer 1. The thermal insulation cement mortar layer 2 is poured on the upper surface of the waterproof cloth layer 10 . The thermal insulation cement mortar layer 2 is prepared from the follow...

Embodiment 2

[0059] The difference between embodiment 2 and embodiment 1 is: refer to Figure 7 There is an air circulation mechanism 9 connected between the second thermal insulation area 30 and the room, which can circulate the oxygen generated by the green plants 86 to the room to improve the indoor air quality. The air circulation mechanism 9 includes a first connecting pipe 91, an air exhaust fan 92, a second connecting pipe 93, and an air supply fan 94. One end of the first connecting pipe 91 communicates with the second thermal insulation area 30 and the other end communicates with the room. The exhaust fan 92 is fixedly connected in the first connecting pipe 91 and is used to draw indoor air into the second thermal insulation area 30 . One end of the second connecting pipe 93 communicates with the second thermal insulation area 30 and the other end communicates with the room. The air supply fan 94 is fixedly connected in the second connecting pipe 93, and is used for transporting ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com