Laser beam coaxial same-wave-surface control system and method

A control system and laser beam technology, applied in the field of optical engineering, can solve the problem of not considering the performance degradation of beam combining, and achieve the effects of short response time, elimination of coaxial wave plane error, pointing error and focal plane error

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

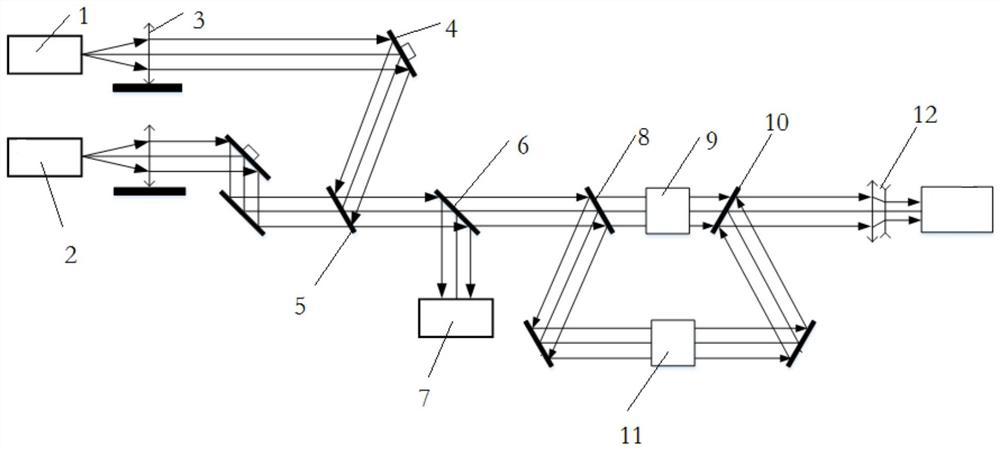

[0071] Such as figure 1 As shown, a laser beam coaxial coaxial control system includes: multiple input sub-beam lasers, sampling mirror 6, beam splitting unit and processor, wherein the wavelengths of multiple input sub-beam lasers are different, and the input sub-beams There are no less than 2 laser beams. The input sub-beam lasers are transmitted to the first beam combining element 5 through the collimation transmission unit to be combined and output to form a beam combining laser. The beam combining lasers are transmitted and reflected by the sampling mirror 6 and then divided into measurement lasers. And the main laser, the main laser can enter the laser emission system 7 to act on the target according to actual needs, the beam separation unit divides the measurement laser into multiple measurement sub-beam lasers, ensuring that the wavefront sensor can separately collect the wavefronts of the multi-channel measurement sub-beam lasers For aberration, the processor calculat...

Embodiment 2

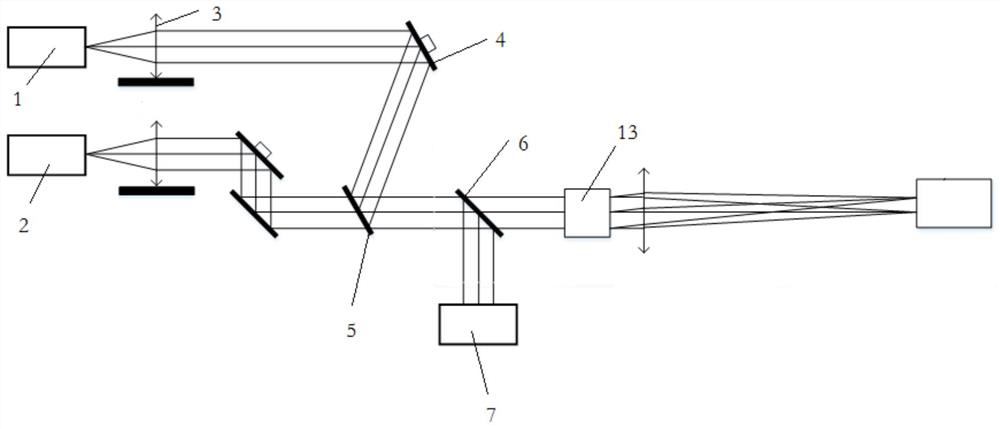

[0093] Such as image 3 As shown, the same parts of this embodiment and Embodiment 1 will not be repeated, and the difference is:

[0094] The beam splitting unit can also be a dispersive element 13, the dispersive element 13 spatially separates the measuring laser light to form multiple measurement sub-beam lasers, and the multi-channel measurement sub-beam lasers become independent image points on the image sensor, realizing the image sensor The spot information of the multi-channel measurement sub-beam laser is collected in different regions. Further, the number of paths of the measuring sub-beam laser is the same as that of the input sub-beam laser. Preferably, the image sensor is a CCD.

[0095] A control method for a laser beam coaxial coaxial co-wave surface control system, comprising the following steps:

[0096] Step S201, move the dispersive element 13 out of the optical path, adjust the first input sub-beam laser 1, so that the light spots are respectively locate...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com