Welding spot standard curve band fitting system and method

A standard curve, solder joint technology, applied in the field of auto parts manufacturing, can solve problems such as high energy consumption and poor solder joint quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0023] Below in conjunction with accompanying drawing and specific embodiment the present invention is described in further detail:

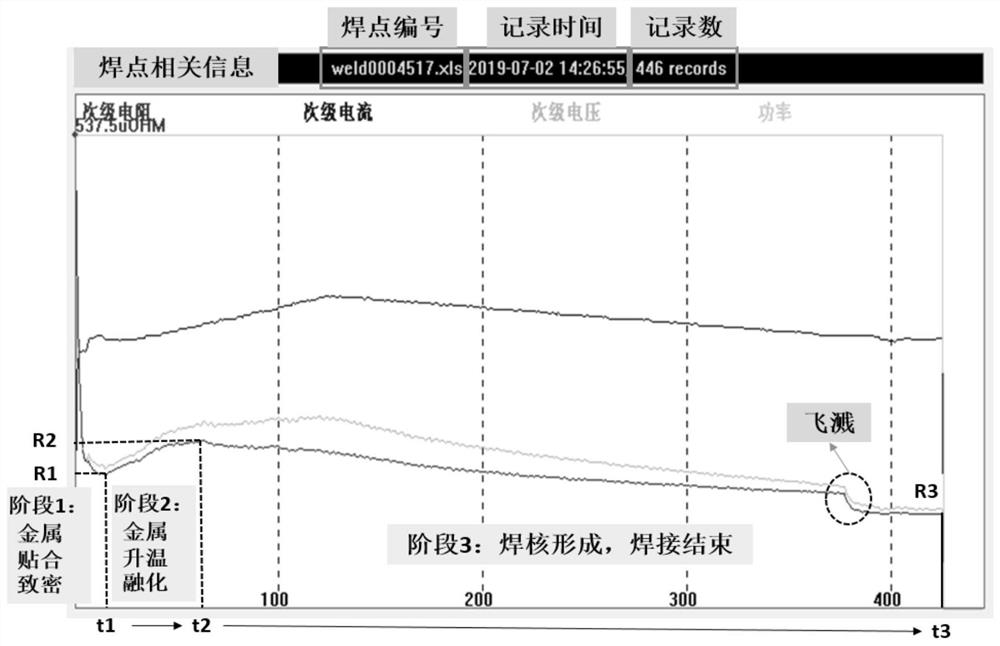

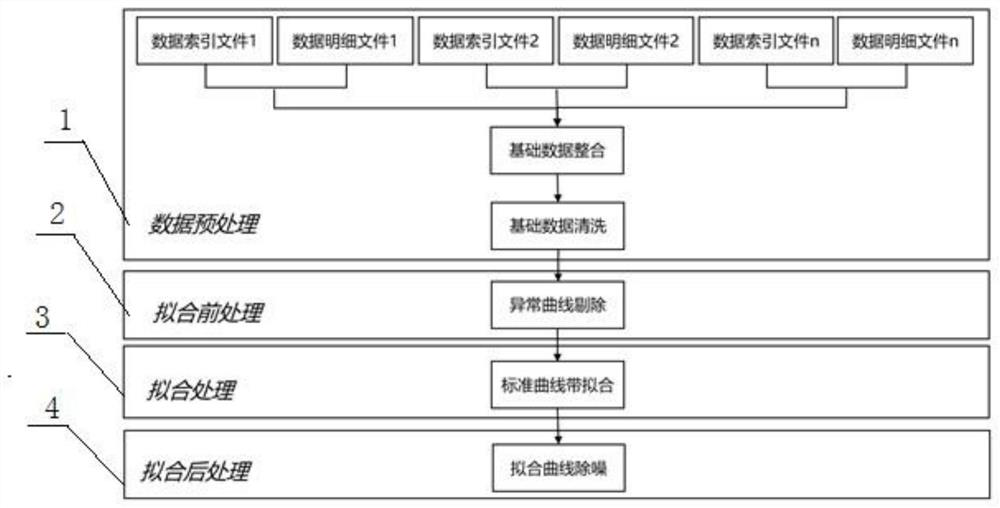

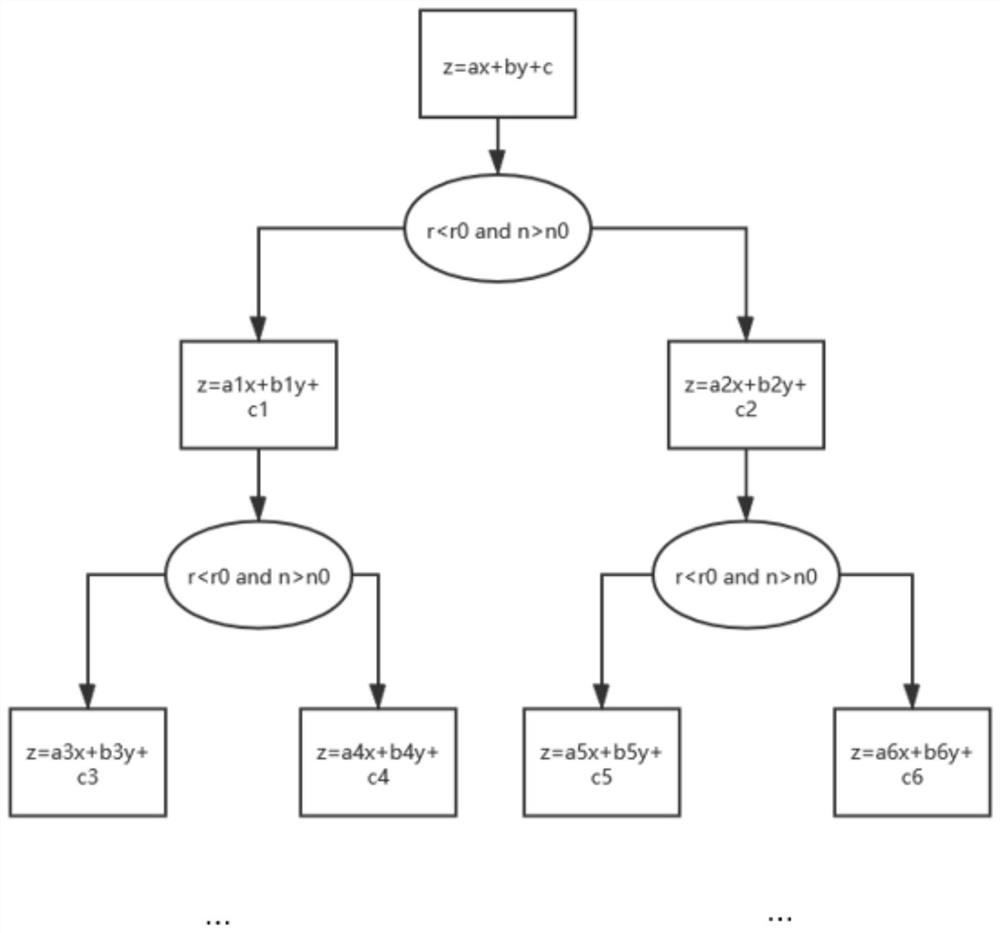

[0024] The solder joint standard curve band refers to the bandwidth formed by many solder joint curves. The actual solder joint data is a table of discrete data points, and there is no analytical formula to describe the relationship between the dynamic characteristic quantities of solder joints (resistance, voltage, current, energy consumption) and welding time. The so-called curve fitting method is to establish a data relationship (mathematical model) by given discrete data points, and find a series of tiny straight line segments to connect these interpolation points into a curve to form a smooth curve. It reflects the functional relationship between the welding object and the object to be welded under the condition of excluding the disturbance factors of the solder joint dynamic characteristics (resistance, voltage, current, energy consumption...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com